. A complete Parts List is available at www.HobartWelders.com

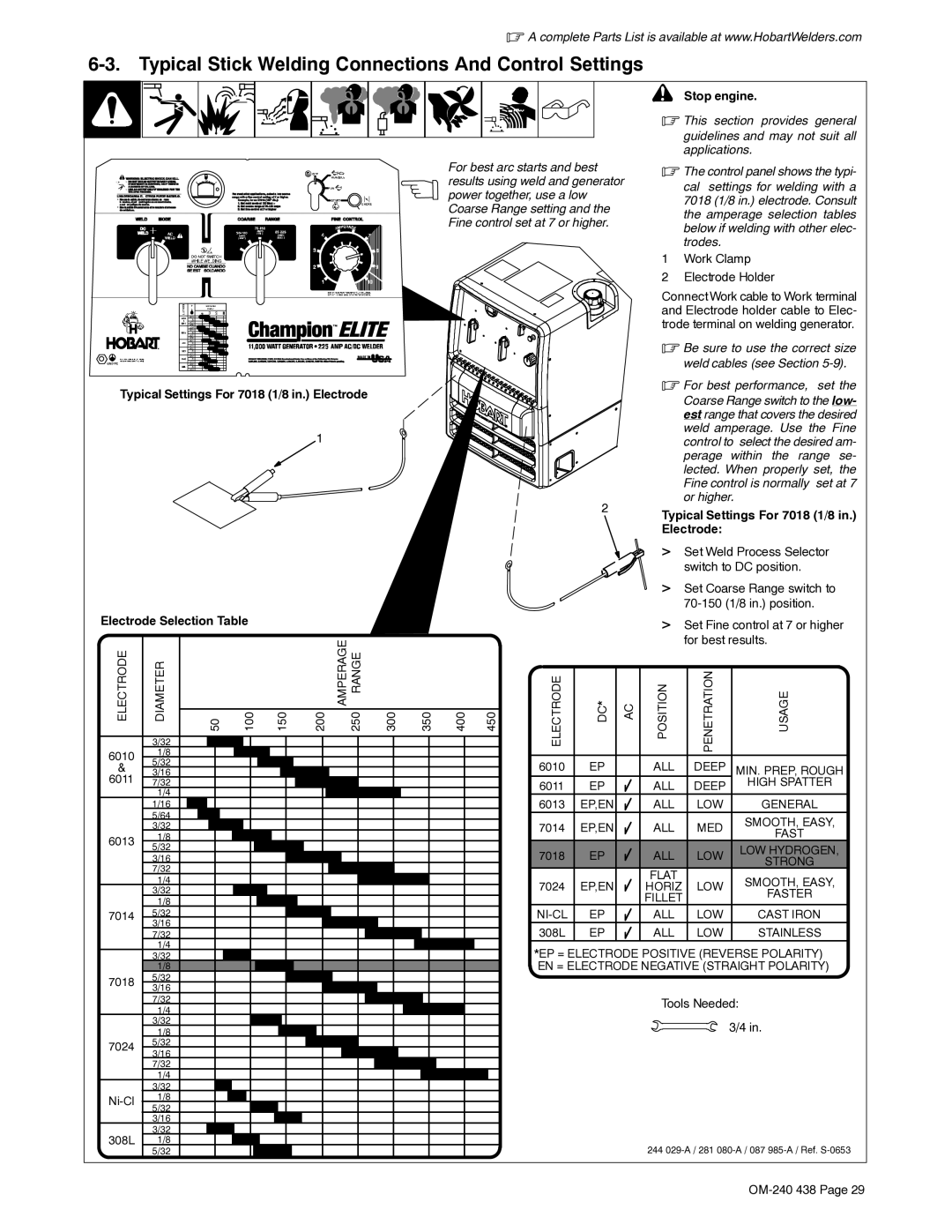

6-3. Typical Stick Welding Connections And Control Settings

! Stop engine.

|

|

|

|

|

|

|

|

|

|

|

|

| . This section provides general | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

| guidelines and may not suit all | |

|

|

|

|

|

|

|

|

|

|

|

|

|

| applications. | |

|

|

|

|

|

|

|

| For best arc starts and best |

| . The control panel shows the typi- | |||||

|

|

|

|

|

|

|

| results using weld and generator |

| cal settings for welding with a | |||||

|

|

|

|

|

|

|

| power together, use a low |

|

| |||||

|

|

|

|

|

|

|

|

|

| 7018 (1/8 in.) electrode. Consult | |||||

|

|

|

|

|

|

|

| Coarse Range setting and the |

|

| |||||

|

|

|

|

|

|

|

|

|

| the amperage selection tables | |||||

|

|

|

|

|

|

|

| Fine control set at 7 or higher. |

|

| |||||

|

|

|

|

|

|

|

|

|

| below if welding with other elec- | |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

| trodes. |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1 | Work Clamp | |

|

|

|

|

|

|

|

|

|

|

|

|

| 2 | Electrode Holder | |

|

|

|

|

|

|

|

|

|

|

|

|

| Connect Work cable to Work terminal | ||

|

|

|

|

|

|

|

|

|

|

|

|

| and Electrode holder cable to Elec- | ||

|

|

|

|

|

|

|

|

|

|

|

|

| trode terminal on welding generator. | ||

|

|

|

|

|

|

|

|

|

|

|

|

| . Be sure to use the correct size | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

| weld cables (see Section | |

Typical Settings For 7018 (1/8 in.) Electrode |

|

|

|

|

|

|

| . For best performance, set the | |||||||

|

|

|

|

|

|

|

| Coarse Range switch to the low- | |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

| est range that covers the desired | |

|

|

|

|

| 1 |

|

|

|

|

|

|

|

| weld amperage. Use the Fine | |

|

|

|

|

|

|

|

|

|

|

|

|

| control to | select the desired am- | |

|

|

|

|

|

|

|

|

|

|

|

|

|

| perage within the range se- | |

|

|

|

|

|

|

|

|

|

|

|

|

|

| lected. When properly set, the | |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Fine control is normally set at 7 | |

|

|

|

|

|

|

|

|

|

|

| 2 |

|

| or higher. |

|

|

|

|

|

|

|

|

|

|

|

|

| Typical Settings For 7018 (1/8 in.) | |||

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

| Electrode: |

| |

|

|

|

|

|

|

|

|

|

|

|

|

| > Set Weld Process Selector | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

| switch to DC position. | |

|

|

|

|

|

|

|

|

|

|

|

|

| > Set Coarse Range switch to | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

Electrode Selection Table |

|

|

|

|

|

|

|

|

| > Set Fine control at 7 or higher | |||||

|

|

|

|

|

|

|

|

|

|

|

|

| |||

ELECTRODE |

|

| 100 | 150 | 200 AMPERAGE 250 RANGE | 300 | 350 | 400 | 450 | ELECTRODE | DC* |

| POSITION | for best results. | |

DIAMETER | 50 | AC | PENETRATION | USAGE | |||||||||||

| 3/32 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6010 | 1/8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

& | 5/32 |

|

|

|

|

|

|

|

| 6010 | EP |

| ALL | DEEP | MIN. PREP, ROUGH |

3/16 |

|

|

|

|

|

|

|

|

| ||||||

6011 | 7/32 |

|

|

|

|

|

|

|

| 6011 | EP |

| ALL | DEEP | HIGH SPATTER |

| 1/4 |

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

| 6013 | EP,EN |

| ALL | LOW | GENERAL | |

| 1/16 |

|

|

|

|

|

|

|

|

| |||||

| 5/64 |

|

|

|

|

|

|

|

|

|

|

|

|

| SMOOTH, EASY, |

| 3/32 |

|

|

|

|

|

|

|

| 7014 | EP,EN |

| ALL | MED | |

|

|

|

|

|

|

|

|

|

| FAST | |||||

6013 | 1/8 |

|

|

|

|

|

|

|

|

|

|

|

|

| |

5/32 |

|

|

|

|

|

|

|

|

|

|

|

|

| LOW HYDROGEN, | |

|

|

|

|

|

|

|

|

| 7018 | EP |

| ALL | LOW | ||

| 3/16 |

|

|

|

|

|

|

|

|

| STRONG | ||||

| 7/32 |

|

|

|

|

|

|

|

|

|

|

| FLAT |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

| 1/4 |

|

|

|

|

|

|

|

|

|

|

|

| SMOOTH, EASY, | |

|

|

|

|

|

|

|

|

| 7024 | EP,EN |

| HORIZ | LOW | ||

| 3/32 |

|

|

|

|

|

|

|

|

| FASTER | ||||

|

|

|

|

|

|

|

|

|

|

|

| FILLET |

| ||

| 1/8 |

|

|

|

|

|

|

|

|

|

|

|

|

| |

7014 | 5/32 |

|

|

|

|

|

|

|

| EP |

| ALL | LOW | CAST IRON | |

| 3/16 |

|

|

|

|

|

|

|

| 308L | EP |

| ALL | LOW | STAINLESS |

| 7/32 |

|

|

|

|

|

|

|

|

| |||||

| 1/4 |

|

|

|

|

|

|

|

| *EP = ELECTRODE POSITIVE (REVERSE POLARITY) | |||||

| 3/32 |

|

|

|

|

|

|

|

| ||||||

| 1/8 |

|

|

|

|

|

|

|

| EN = ELECTRODE NEGATIVE (STRAIGHT POLARITY) | |||||

7018 | 5/32 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3/16 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| 7/32 |

|

|

|

|

|

|

|

|

|

|

| Tools Needed: | ||

| 1/4 |

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| 3/32 |

|

|

|

|

|

|

|

|

|

|

|

| 3/4 in. | |

| 1/8 |

|

|

|

|

|

|

|

|

|

|

|

| ||

7024 | 5/32 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3/16 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| 7/32 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1/4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 3/32 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1/8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

5/32 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| 3/16 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

308L | 3/32 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1/8 |

|

|

|

|

|

|

|

|

|

|

| 244 | |||

| 5/32 |

|

|

|

|

|

|

|

|

|

|

| |||