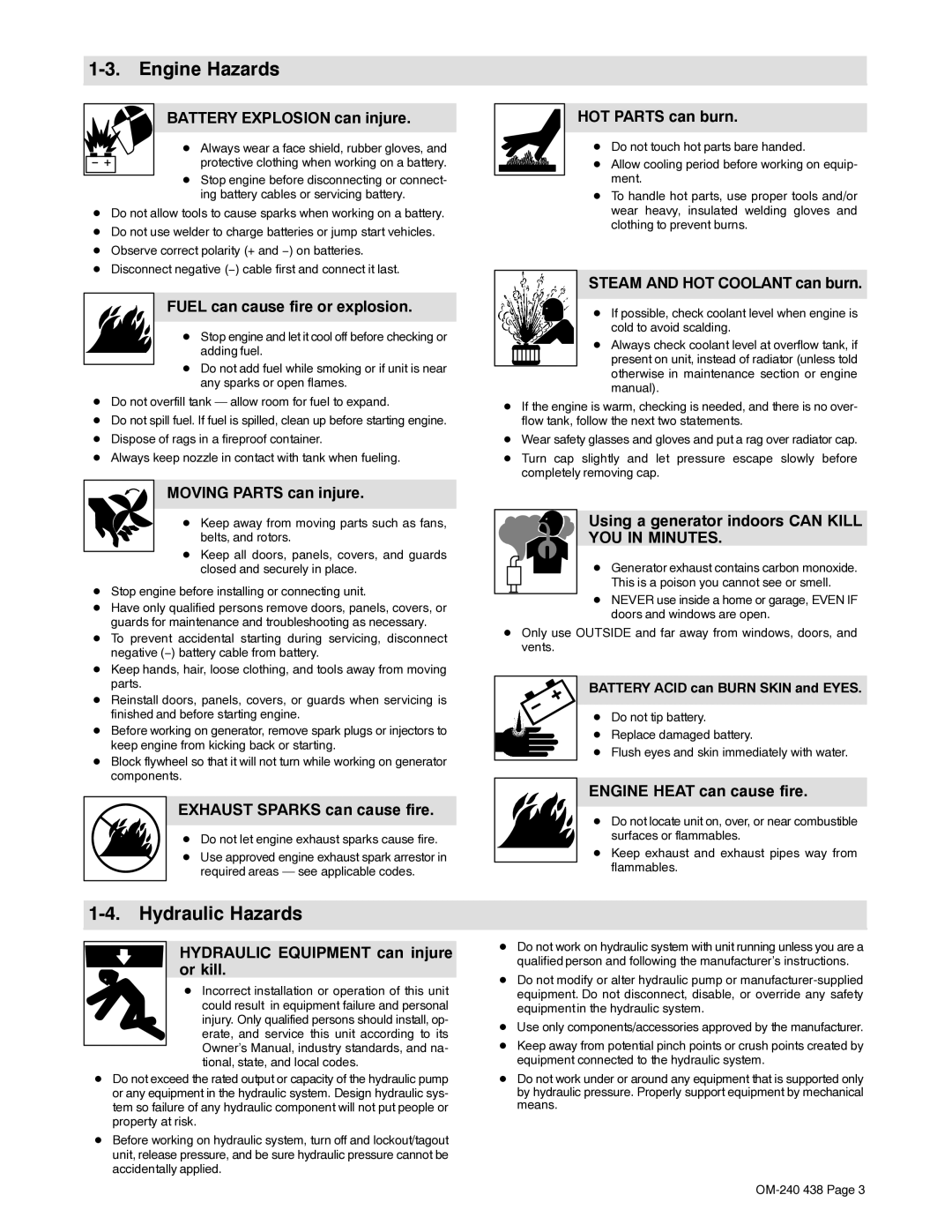

1-3. Engine Hazards

BATTERY EXPLOSION can injure.

DAlways wear a face shield, rubber gloves, and

protective clothing when working on a battery.

D Stop engine before disconnecting or connect- ing battery cables or servicing battery.

DDo not allow tools to cause sparks when working on a battery.

DDo not use welder to charge batteries or jump start vehicles.

DObserve correct polarity (+ and −) on batteries.

DDisconnect negative (−) cable first and connect it last.

FUEL can cause fire or explosion.

D Stop engine and let it cool off before checking or adding fuel.

DDo not add fuel while smoking or if unit is near any sparks or open flames.

DDo not overfill tank — allow room for fuel to expand.

DDo not spill fuel. If fuel is spilled, clean up before starting engine.

DDispose of rags in a fireproof container.

DAlways keep nozzle in contact with tank when fueling.

MOVING PARTS can injure.

D Keep away from moving parts such as fans, belts, and rotors.

DKeep all doors, panels, covers, and guards closed and securely in place.

DStop engine before installing or connecting unit.

DHave only qualified persons remove doors, panels, covers, or guards for maintenance and troubleshooting as necessary.

DTo prevent accidental starting during servicing, disconnect negative (−) battery cable from battery.

DKeep hands, hair, loose clothing, and tools away from moving parts.

DReinstall doors, panels, covers, or guards when servicing is finished and before starting engine.

DBefore working on generator, remove spark plugs or injectors to keep engine from kicking back or starting.

DBlock flywheel so that it will not turn while working on generator components.

EXHAUST SPARKS can cause fire.

D Do not let engine exhaust sparks cause fire.

DUse approved engine exhaust spark arrestor in required areas — see applicable codes.

HOT PARTS can burn.

DDo not touch hot parts bare handed.

D Allow cooling period before working on equip- ment.

DTo handle hot parts, use proper tools and/or wear heavy, insulated welding gloves and clothing to prevent burns.

STEAM AND HOT COOLANT can burn.

DIf possible, check coolant level when engine is cold to avoid scalding.

D Always check coolant level at overflow tank, if present on unit, instead of radiator (unless told otherwise in maintenance section or engine manual).

DIf the engine is warm, checking is needed, and there is no over- flow tank, follow the next two statements.

DWear safety glasses and gloves and put a rag over radiator cap.

DTurn cap slightly and let pressure escape slowly before completely removing cap.

Using a generator indoors CAN KILL YOU IN MINUTES.

D Generator exhaust contains carbon monoxide.

This is a poison you cannot see or smell.

DNEVER use inside a home or garage, EVEN IF doors and windows are open.

DOnly use OUTSIDE and far away from windows, doors, and vents.

BATTERY ACID can BURN SKIN and EYES.

DDo not tip battery.

DReplace damaged battery.

DFlush eyes and skin immediately with water.

ENGINE HEAT can cause fire.

D Do not locate unit on, over, or near combustible surfaces or flammables.

DKeep exhaust and exhaust pipes way from flammables.

1-4. Hydraulic Hazards

HYDRAULIC EQUIPMENT can injure or kill.

DIncorrect installation or operation of this unit could result in equipment failure and personal injury. Only qualified persons should install, op- erate, and service this unit according to its Owner’s Manual, industry standards, and na- tional, state, and local codes.

DDo not exceed the rated output or capacity of the hydraulic pump or any equipment in the hydraulic system. Design hydraulic sys- tem so failure of any hydraulic component will not put people or property at risk.

DBefore working on hydraulic system, turn off and lockout/tagout unit, release pressure, and be sure hydraulic pressure cannot be accidentally applied.

DDo not work on hydraulic system with unit running unless you are a qualified person and following the manufacturer’s instructions.

DDo not modify or alter hydraulic pump or

DUse only components/accessories approved by the manufacturer.

DKeep away from potential pinch points or crush points created by equipment connected to the hydraulic system.

DDo not work under or around any equipment that is supported only by hydraulic pressure. Properly support equipment by mechanical means.