. A complete Parts List is available at www.HobartWelders.com

SECTION 6 − OPERATING THE WELDING GENERATOR

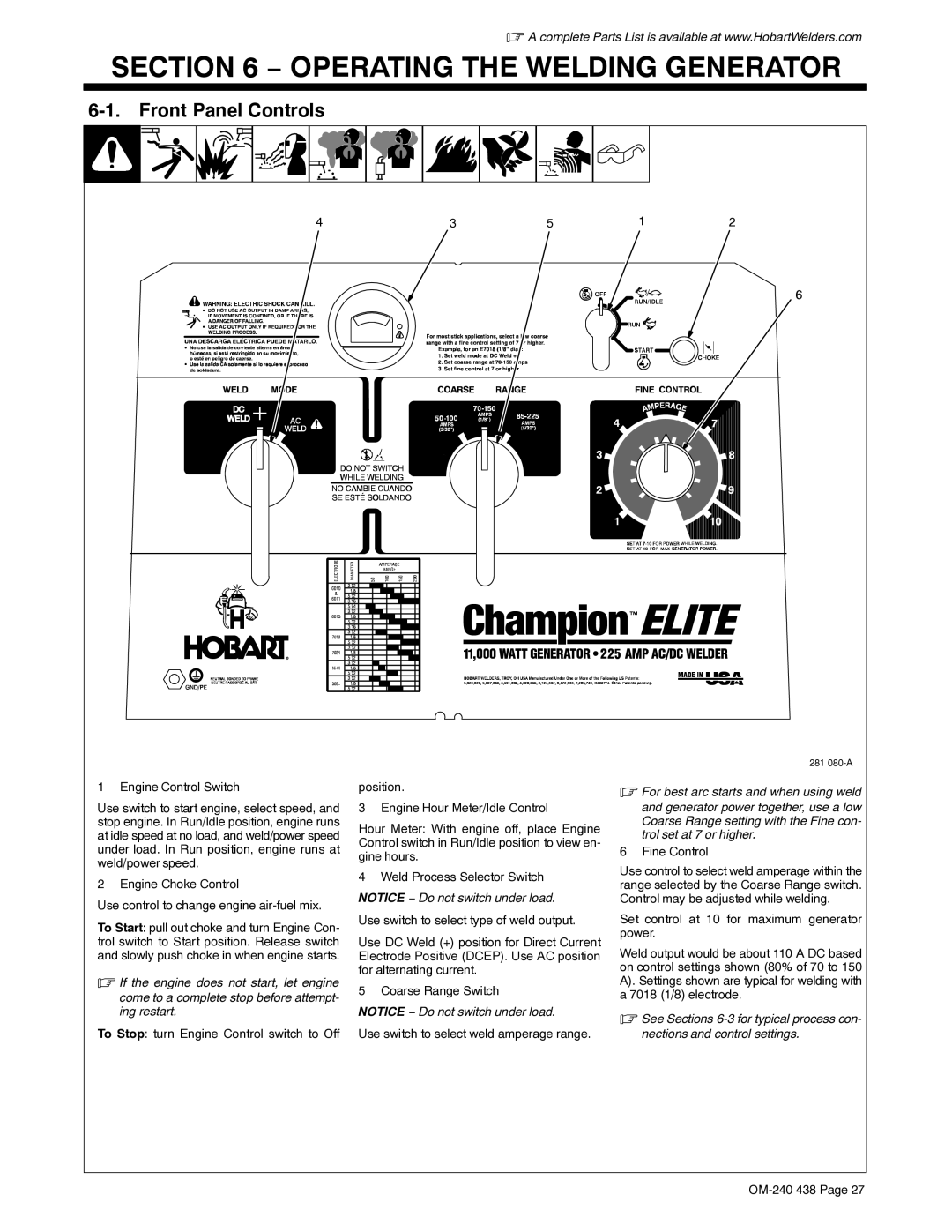

6-1. Front Panel Controls

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1 |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

4 | 3 | 5 |

| 2 | ||||||||||||

6

1 Engine Control Switch

Use switch to start engine, select speed, and stop engine. In Run/Idle position, engine runs at idle speed at no load, and weld/power speed under load. In Run position, engine runs at weld/power speed.

2 Engine Choke Control

Use control to change engine

To Start: pull out choke and turn Engine Con- trol switch to Start position. Release switch and slowly push choke in when engine starts.

.If the engine does not start, let engine come to a complete stop before attempt- ing restart.

To Stop: turn Engine Control switch to Off

position.

3 Engine Hour Meter/Idle Control

Hour Meter: With engine off, place Engine Control switch in Run/Idle position to view en- gine hours.

4Weld Process Selector Switch NOTICE − Do not switch under load. Use switch to select type of weld output.

Use DC Weld (+) position for Direct Current Electrode Positive (DCEP). Use AC position for alternating current.

5 Coarse Range Switch

NOTICE − Do not switch under load.

Use switch to select weld amperage range.

281

.For best arc starts and when using weld

and generator power together, use a low Coarse Range setting with the Fine con- trol set at 7 or higher.

6 Fine Control

Use control to select weld amperage within the range selected by the Coarse Range switch. Control may be adjusted while welding.

Set control at 10 for maximum generator power.

Weld output would be about 110 A DC based on control settings shown (80% of 70 to 150 A). Settings shown are typical for welding with a 7018 (1/8) electrode.

.See Sections