Adjusting Gibs

Gibs control the accuracy of the carriage, cross slide, and compound slide movements along the ways. Tight gibs make the movements more accurate, but harder to perform. Loose gibs make the movements sloppy, but easier to perform. The goal of gib adjustment is to remove unnecessary sloppiness without causing the ways to bind.

NOTICE

Excessively loose gibs may cause poor workpiece finishes, and may cause undue wear of sliding surfaces and ways. Over- tightening the gibs may cause premature wear of these sliding devices.

Tools Needed | Qty |

Hex Wrench 6mm | 1 |

Wrench 14mm | 1 |

To adjust the saddle gib: |

|

1.DISCONNECT LATHE FROM POWER!

2.Loosen the three hex nuts one full turn (see

Figure 95).

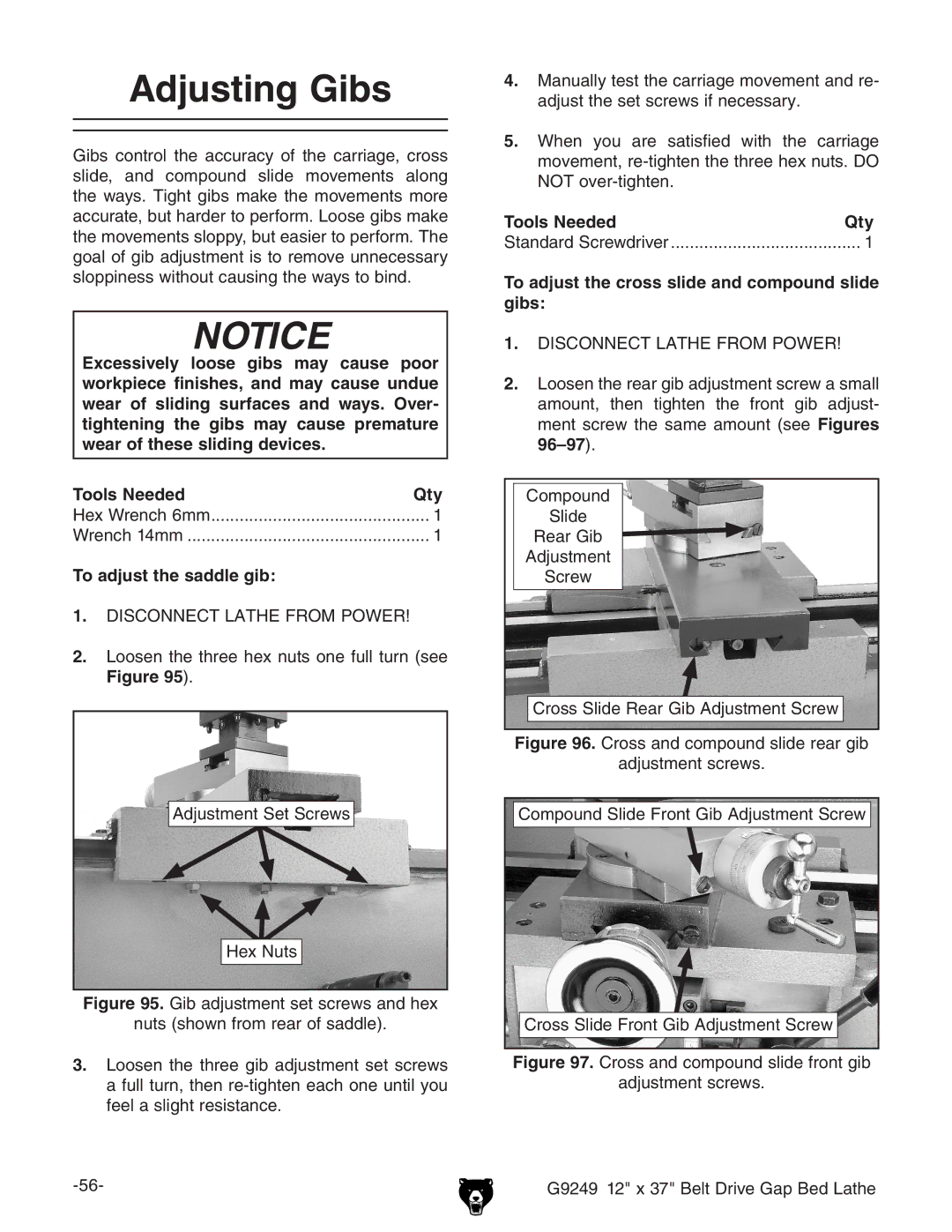

Adjustment Set Screws

Hex Nuts

Figure 95. Gib adjustment set screws and hex

nuts (shown from rear of saddle).

3.Loosen the three gib adjustment set screws a full turn, then re-tighten each one until you feel a slight resistance.

4.Manually test the carriage movement and re- adjust the set screws if necessary.

5.When you are satisfied with the carriage movement, re-tighten the three hex nuts. DO NOT over-tighten.

Tools Needed | Qty |

Standard Screwdriver | ......................................... 1 |

To adjust the cross slide and compound slide gibs:

1.DISCONNECT LATHE FROM POWER!

2.Loosen the rear gib adjustment screw a small amount, then tighten the front gib adjust- ment screw the same amount (see Figures

Compound |

Slide |

Rear Gib |

Adjustment |

Screw |

Cross Slide Rear Gib Adjustment Screw |

Figure 96. Cross and compound slide rear gib

adjustment screws.

Compound Slide Front Gib Adjustment Screw |

Cross Slide Front Gib Adjustment Screw |

Figure 97. Cross and compound slide front gib

adjustment screws.

G9249 12" x 37" Belt Drive Gap Bed Lathe |