Steady Rest

The steady rest serves as a support for long shafts where the length to diameter ratio is 3:1 or greater. The steady rest can be positioned anywhere along the length of the workpiece or bedway.

Tools Needed | Qty |

Wrench 19mm | 1 |

Wrench 10mm | 1 |

Standard Screwdriver #1 | 1 |

To install and use the steady rest:

1.Remove the clamp hex nut, flat washer, and clamp block from the bottom of the steady rest.

2.Clean away any debris or grime from the bedways, the steady rest ways, and the clamp block.

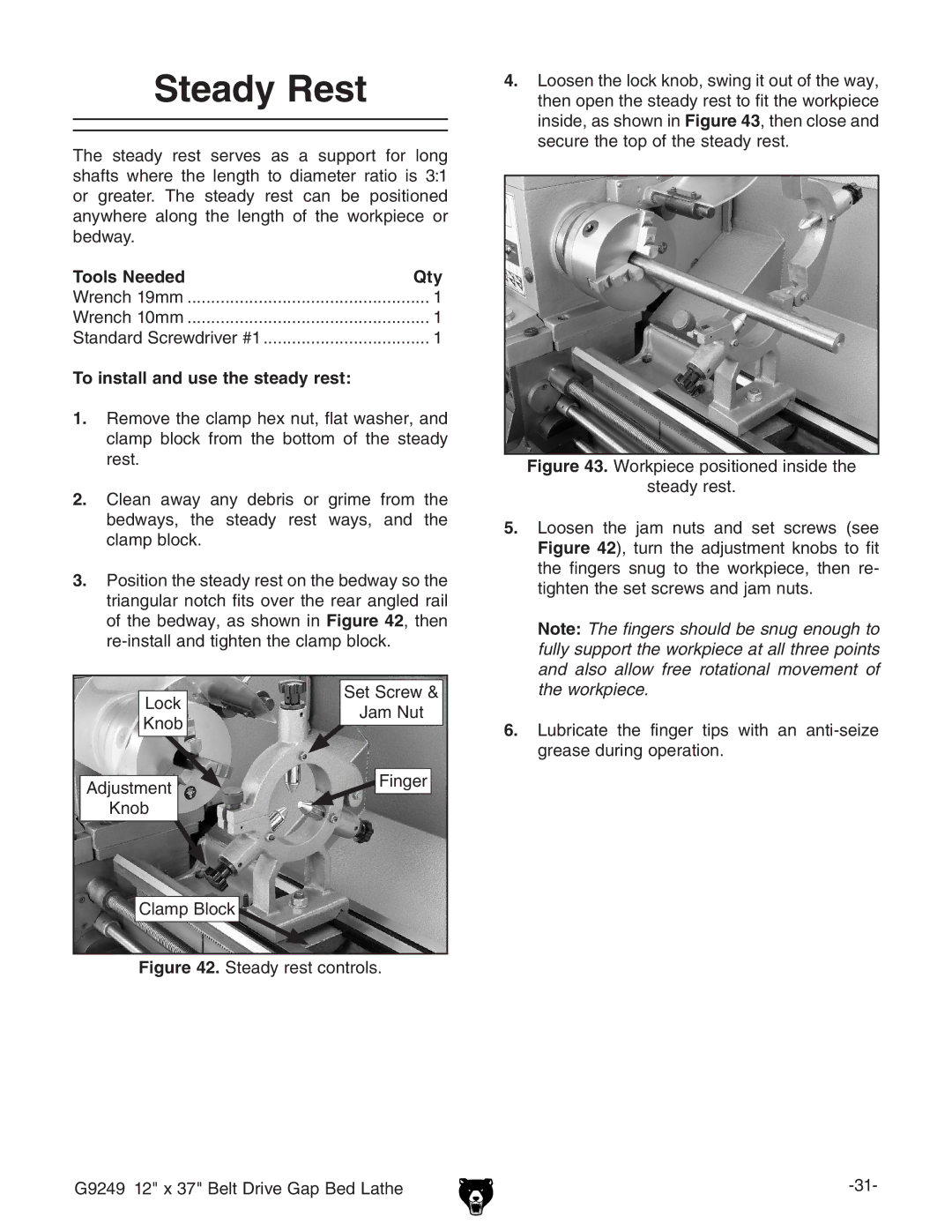

3.Position the steady rest on the bedway so the triangular notch fits over the rear angled rail of the bedway, as shown in Figure 42, then

Lock | Set Screw & | |

Jam Nut | ||

Knob | ||

| ||

Adjustment | Finger | |

| ||

Knob |

| |

Clamp Block |

|

Figure 42. Steady rest controls.

4.Loosen the lock knob, swing it out of the way, then open the steady rest to fit the workpiece inside, as shown in Figure 43, then close and secure the top of the steady rest.

Figure 43. Workpiece positioned inside the

steady rest.

5.Loosen the jam nuts and set screws (see Figure 42), turn the adjustment knobs to fit the fingers snug to the workpiece, then re- tighten the set screws and jam nuts.

Note: The fingers should be snug enough to fully support the workpiece at all three points and also allow free rotational movement of the workpiece.

6.Lubricate the finger tips with an anti-seize grease during operation.

G9249 12" x 37" Belt Drive Gap Bed Lathe |