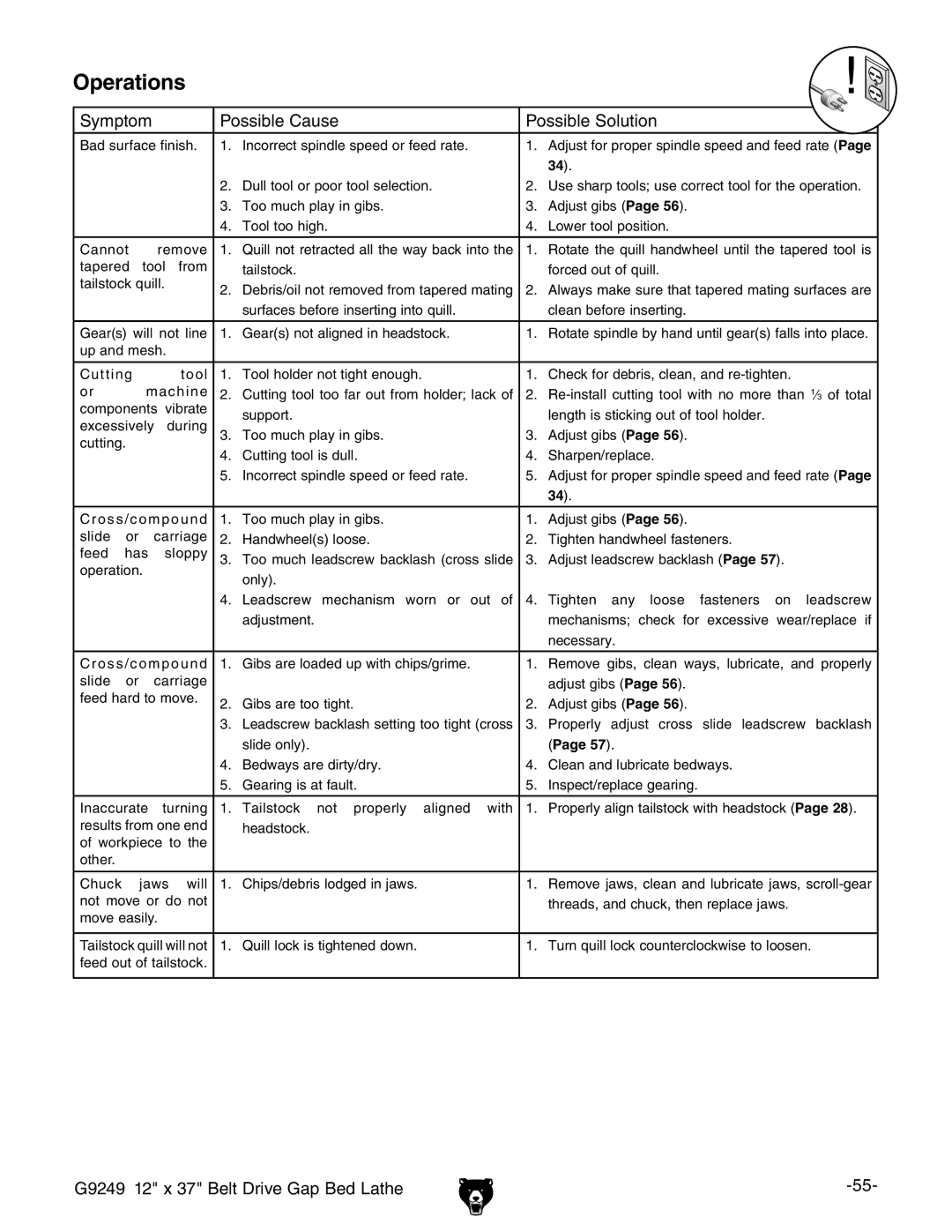

Operations

Symptom |

|

| Possible Cause | Possible Solution | ||||

Bad surface finish. | 1. | Incorrect spindle speed or feed rate. | 1. | Adjust for proper spindle speed and feed rate (Page | ||||

|

|

|

|

|

|

|

| 34). |

|

|

|

|

| 2. | Dull tool or poor tool selection. | 2. | Use sharp tools; use correct tool for the operation. |

|

|

|

|

| 3. | Too much play in gibs. | 3. | Adjust gibs (Page 56). |

|

|

|

|

| 4. | Tool too high. | 4. | Lower tool position. |

|

|

|

|

|

|

| ||

Cannot |

| remove | 1. | Quill not retracted all the way back into the | 1. | Rotate the quill handwheel until the tapered tool is | ||

tapered | tool | from |

| tailstock. |

| forced out of quill. | ||

tailstock quill. |

| 2. | Debris/oil not removed from tapered mating | 2. | Always make sure that tapered mating surfaces are | |||

|

|

|

|

| ||||

|

|

|

|

|

| surfaces before inserting into quill. |

| clean before inserting. |

|

|

|

|

| ||||

Gear(s) will not line | 1. | Gear(s) not aligned in headstock. | 1. | Rotate spindle by hand until gear(s) falls into place. | ||||

up and mesh. |

|

|

|

|

| |||

|

|

|

|

|

|

|

| |

Cutting |

|

| tool | 1. | Tool holder not tight enough. | 1. | Check for debris, clean, and | |

or |

| machine | 2. | Cutting tool too far out from holder; lack of | 2. | |||

components vibrate |

| support. |

| length is sticking out of tool holder. | ||||

excessively | during |

|

| |||||

3. | Too much play in gibs. | 3. | Adjust gibs (Page 56). | |||||

cutting. |

|

|

| 4. | Cutting tool is dull. | 4. | Sharpen/replace. | |

|

|

|

|

| ||||

|

|

|

|

| 5. | Incorrect spindle speed or feed rate. | 5. | Adjust for proper spindle speed and feed rate (Page |

|

|

|

|

|

|

|

| 34). |

|

|

|

|

| ||||

Cross/compound | 1. | Too much play in gibs. | 1. | Adjust gibs (Page 56). | ||||

slide | or | carriage | 2. | Handwheel(s) loose. | 2. | Tighten handwheel fasteners. | ||

feed | has | sloppy | 3. | Too much leadscrew backlash (cross slide | 3. | Adjust leadscrew backlash (Page 57). | ||

operation. |

|

|

| only). |

|

| ||

|

|

|

|

|

|

|

| |

|

|

|

|

| 4. | Leadscrew mechanism worn or out of | 4. | Tighten any loose fasteners on leadscrew |

|

|

|

|

|

| adjustment. |

| mechanisms; check for excessive wear/replace if |

|

|

|

|

|

|

|

| necessary. |

|

|

|

|

| ||||

Cross/compound | 1. | Gibs are loaded up with chips/grime. | 1. | Remove gibs, clean ways, lubricate, and properly | ||||

slide | or | carriage |

|

|

| adjust gibs (Page 56). | ||

feed hard to move. | 2. | Gibs are too tight. | 2. | Adjust gibs (Page 56). | ||||

|

|

|

|

| ||||

|

|

|

|

| 3. | Leadscrew backlash setting too tight (cross | 3. | Properly adjust cross slide leadscrew backlash |

|

|

|

|

|

| slide only). |

| (Page 57). |

|

|

|

|

| 4. | Bedways are dirty/dry. | 4. | Clean and lubricate bedways. |

|

|

|

|

| 5. | Gearing is at fault. | 5. | Inspect/replace gearing. |

|

|

|

|

|

| |||

Inaccurate | turning | 1. | Tailstock not properly aligned with | 1. | Properly align tailstock with headstock (Page 28). | |||

results from one end |

| headstock. |

|

| ||||

of workpiece to the |

|

|

|

| ||||

other. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Chuck |

| jaws | will | 1. | Chips/debris lodged in jaws. | 1. | Remove jaws, clean and lubricate jaws, | |

not move or do not |

|

|

| threads, and chuck, then replace jaws. | ||||

move easily. |

|

|

|

|

| |||

|

|

|

|

| ||||

Tailstock quill will not | 1. | Quill lock is tightened down. | 1. | Turn quill lock counterclockwise to loosen. | ||||

feed out of tailstock. |

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

G9249 12" x 37" Belt Drive Gap Bed Lathe |