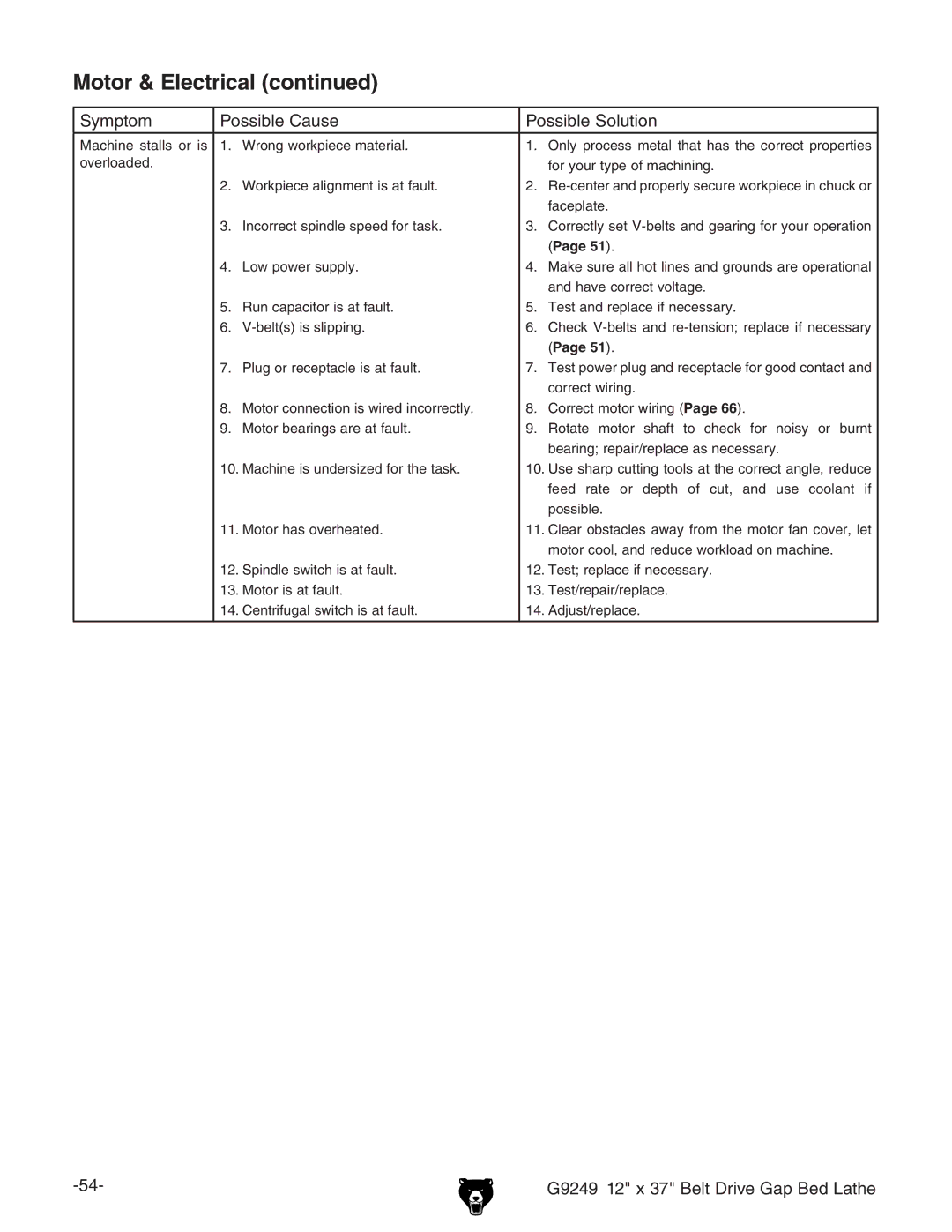

Motor & Electrical (continued)

Symptom | Possible Cause | Possible Solution | ||

Machine stalls or is | 1. | Wrong workpiece material. | 1. | Only process metal that has the correct properties |

overloaded. |

|

|

| for your type of machining. |

| 2. | Workpiece alignment is at fault. | 2. | |

|

|

|

| faceplate. |

| 3. | Incorrect spindle speed for task. | 3. | Correctly set |

|

|

|

| (Page 51). |

| 4. | Low power supply. | 4. | Make sure all hot lines and grounds are operational |

|

|

|

| and have correct voltage. |

| 5. | Run capacitor is at fault. | 5. | Test and replace if necessary. |

| 6. | 6. | Check | |

|

|

|

| (Page 51). |

| 7. | Plug or receptacle is at fault. | 7. | Test power plug and receptacle for good contact and |

|

|

|

| correct wiring. |

| 8. | Motor connection is wired incorrectly. | 8. | Correct motor wiring (Page 66). |

| 9. | Motor bearings are at fault. | 9. | Rotate motor shaft to check for noisy or burnt |

|

|

|

| bearing; repair/replace as necessary. |

| 10. Machine is undersized for the task. | 10. Use sharp cutting tools at the correct angle, reduce | ||

|

|

|

| feed rate or depth of cut, and use coolant if |

|

|

|

| possible. |

| 11. Motor has overheated. | 11. Clear obstacles away from the motor fan cover, let | ||

|

|

|

| motor cool, and reduce workload on machine. |

| 12. Spindle switch is at fault. | 12. Test; replace if necessary. | ||

| 13. Motor is at fault. | 13. Test/repair/replace. | ||

| 14. Centrifugal switch is at fault. | 14. Adjust/replace. | ||

|

|

|

|

|

G9249 12" x 37" Belt Drive Gap Bed Lathe |