Adjusting Half-Nut

The

The goal of adjusting the

Tools Needed | Qty |

Hex Wrench 3mm | 1 |

Hex Wrench 5mm | 1 |

To adjust the |

|

1.DISCONNECT LATHE FROM POWER!

2.Unscrew the cap screw shown in Figure 107 and remove the thread dial assembly.

![]() Cap Screw

Cap Screw

Thread Dial

Assembly

Figure 107. Thread dial and cap screw.

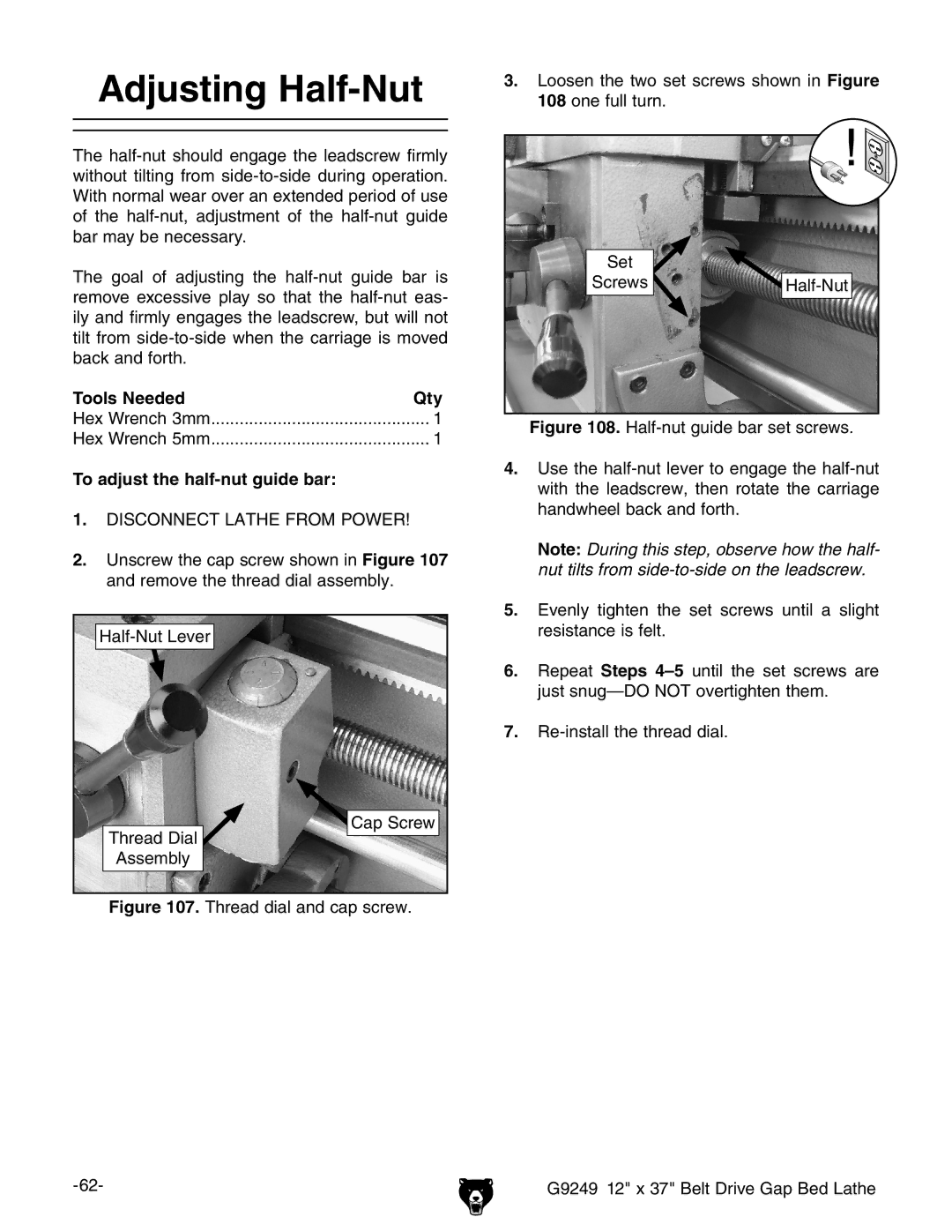

3.Loosen the two set screws shown in Figure 108 one full turn.

Set |

|

Screws |

Figure 108. Half-nut guide bar set screws.

4.Use the half-nut lever to engage the half-nut with the leadscrew, then rotate the carriage handwheel back and forth.

Note: During this step, observe how the half- nut tilts from