D.Feed Direction Lever: Controls direction or stops (center position) the rotation of the feed rod or leadscrew.

E.Feed Rod/Leadscrew Lever: Selects feed rod rotation when positioned to the left, leadscrew rotation when positioned to the right, and stops the rotation of either when in the center position.

F.Feed Rate Selectors: Sets the feed rate of the feed rod or leadscrew.

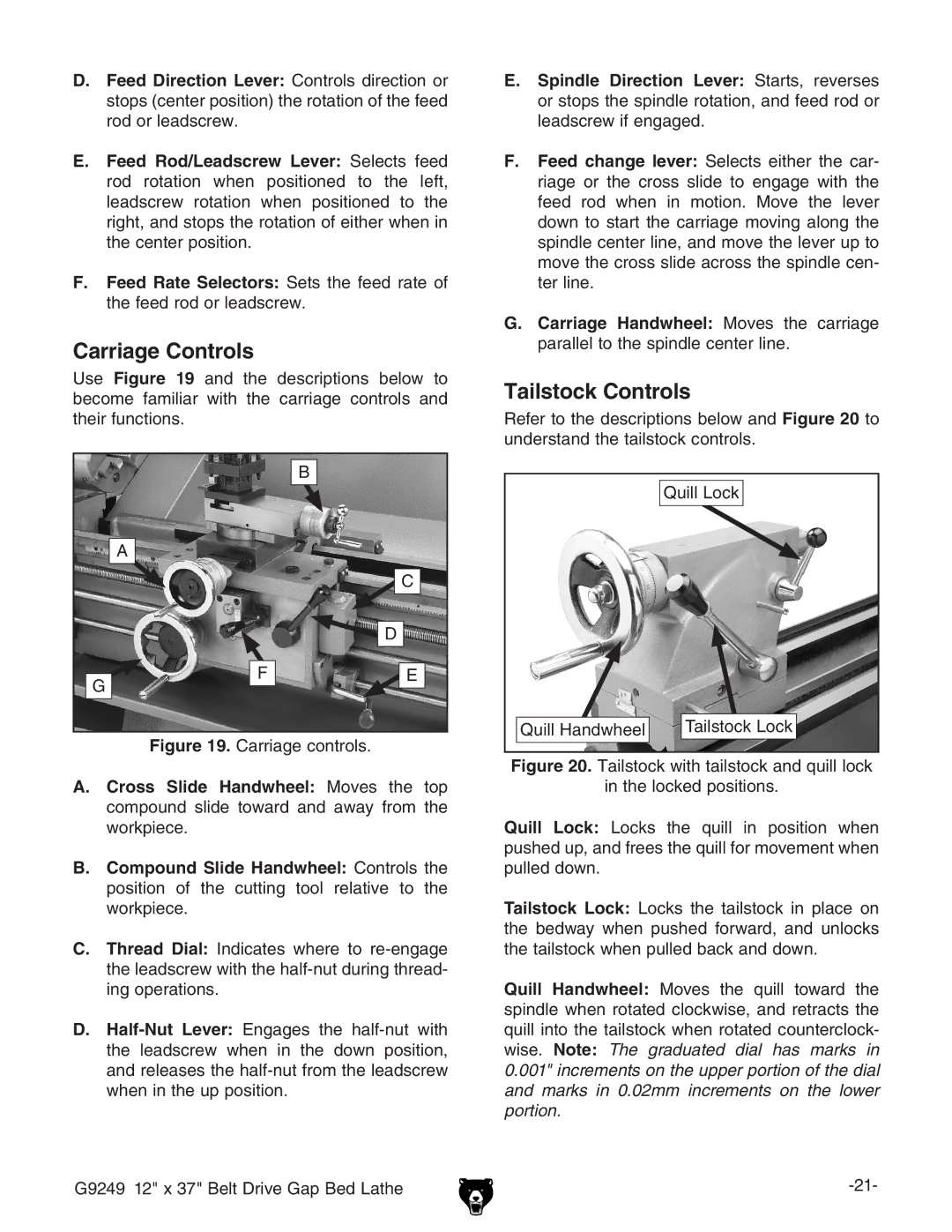

Carriage Controls

Use Figure 19 and the descriptions below to become familiar with the carriage controls and their functions.

E.Spindle Direction Lever: Starts, reverses or stops the spindle rotation, and feed rod or leadscrew if engaged.

F.Feed change lever: Selects either the car- riage or the cross slide to engage with the feed rod when in motion. Move the lever down to start the carriage moving along the spindle center line, and move the lever up to move the cross slide across the spindle cen- ter line.

G.Carriage Handwheel: Moves the carriage parallel to the spindle center line.

Tailstock Controls

Refer to the descriptions below and Figure 20 to understand the tailstock controls.

A

G

F

B

C

![]()

![]() D

D

E

Quill Lock

Figure 19. Carriage controls.

A.Cross Slide Handwheel: Moves the top compound slide toward and away from the workpiece.

B.Compound Slide Handwheel: Controls the position of the cutting tool relative to the workpiece.

C.Thread Dial: Indicates where to re-engage the leadscrew with the half-nut during thread- ing operations.

D.Half-Nut Lever: Engages the half-nut with the leadscrew when in the down position, and releases the half-nut from the leadscrew when in the up position.

G9249 12" x 37" Belt Drive Gap Bed Lathe

Quill Handwheel |

| Tailstock Lock |

|

|

|