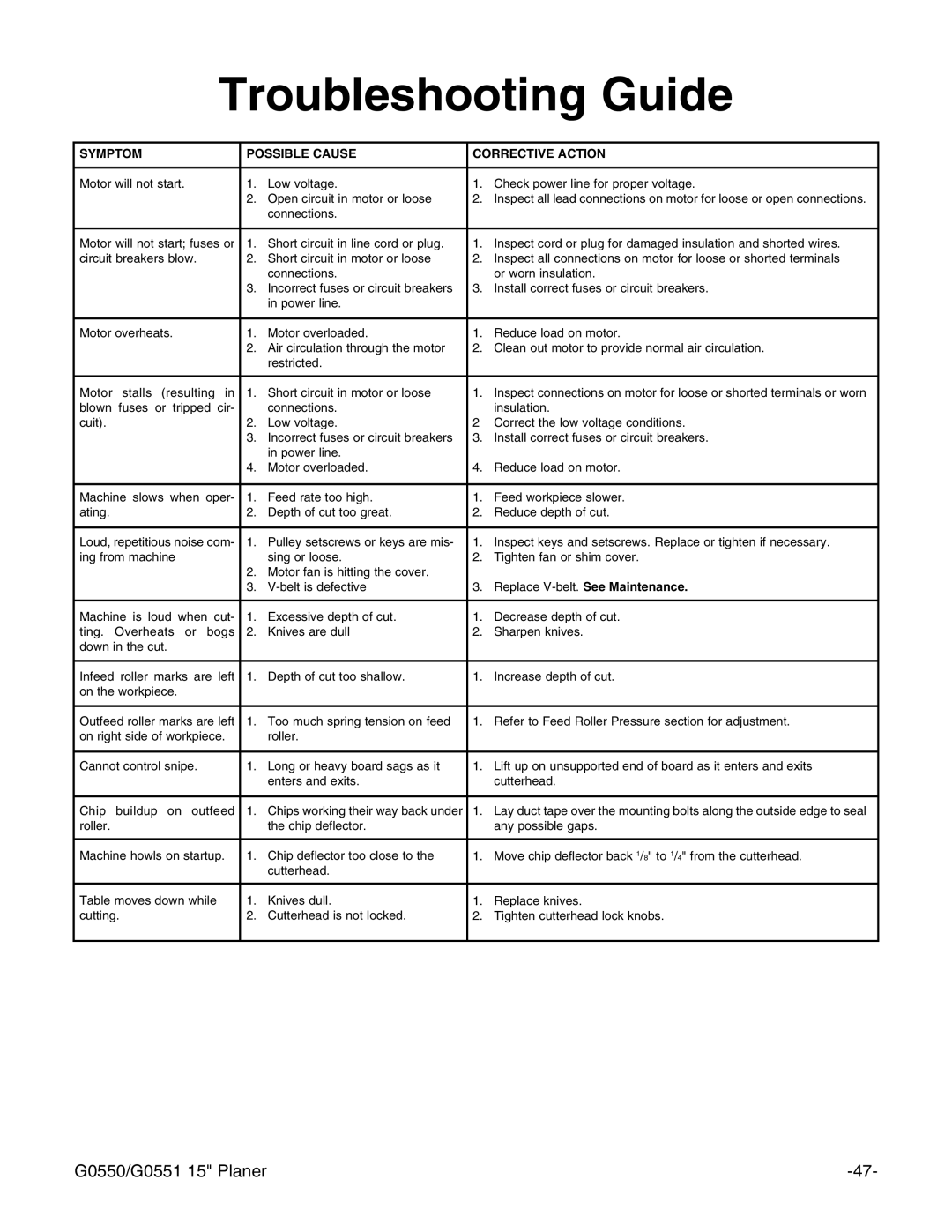

Troubleshooting Guide

SYMPTOM |

| POSSIBLE CAUSE | CORRECTIVE ACTION | |||

|

|

|

|

|

| |

Motor will not start. |

| 1. | Low voltage. | 1. | Check power line for proper voltage. | |

|

|

| 2. | Open circuit in motor or loose | 2. | Inspect all lead connections on motor for loose or open connections. |

|

|

|

| connections. |

|

|

|

|

|

|

| ||

Motor will not start; fuses or | 1. | Short circuit in line cord or plug. | 1. | Inspect cord or plug for damaged insulation and shorted wires. | ||

circuit breakers blow. | 2. | Short circuit in motor or loose | 2. | Inspect all connections on motor for loose or shorted terminals | ||

|

|

|

| connections. |

| or worn insulation. |

|

|

| 3. | Incorrect fuses or circuit breakers | 3. | Install correct fuses or circuit breakers. |

|

|

|

| in power line. |

|

|

|

|

|

|

|

| |

Motor overheats. |

| 1. | Motor overloaded. | 1. | Reduce load on motor. | |

|

|

| 2. | Air circulation through the motor | 2. | Clean out motor to provide normal air circulation. |

|

|

|

| restricted. |

|

|

|

|

|

|

|

| |

Motor | stalls (resulting in | 1. | Short circuit in motor or loose | 1. | Inspect connections on motor for loose or shorted terminals or worn | |

blown fuses or tripped cir- |

| connections. |

| insulation. | ||

cuit). |

|

| 2. | Low voltage. | 2 | Correct the low voltage conditions. |

|

|

| 3. | Incorrect fuses or circuit breakers | 3. | Install correct fuses or circuit breakers. |

|

|

|

| in power line. |

|

|

|

|

| 4. | Motor overloaded. | 4. | Reduce load on motor. |

|

|

|

|

| ||

Machine slows when oper- | 1. | Feed rate too high. | 1. | Feed workpiece slower. | ||

ating. |

|

| 2. | Depth of cut too great. | 2. | Reduce depth of cut. |

|

|

|

|

| ||

Loud, repetitious noise com- | 1. | Pulley setscrews or keys are mis- | 1. | Inspect keys and setscrews. Replace or tighten if necessary. | ||

ing from machine |

|

| sing or loose. | 2. | Tighten fan or shim cover. | |

|

|

| 2. | Motor fan is hitting the cover. |

|

|

|

|

| 3. | 3. | Replace | |

|

|

|

|

| ||

Machine is loud when cut- | 1. | Excessive depth of cut. | 1. | Decrease depth of cut. | ||

ting. | Overheats | or bogs | 2. | Knives are dull | 2. | Sharpen knives. |

down in the cut. |

|

|

|

|

| |

|

|

|

|

| ||

Infeed roller marks are left | 1. | Depth of cut too shallow. | 1. | Increase depth of cut. | ||

on the workpiece. |

|

|

|

|

| |

|

|

|

|

| ||

Outfeed roller marks are left | 1. | Too much spring tension on feed | 1. | Refer to Feed Roller Pressure section for adjustment. | ||

on right side of workpiece. |

| roller. |

|

| ||

|

|

|

|

| ||

Cannot control snipe. | 1. | Long or heavy board sags as it | 1. | Lift up on unsupported end of board as it enters and exits | ||

|

|

|

| enters and exits. |

| cutterhead. |

|

|

|

|

|

|

|

Chip | buildup on | outfeed | 1. | Chips working their way back under | 1. | Lay duct tape over the mounting bolts along the outside edge to seal |

roller. |

|

|

| the chip deflector. |

| any possible gaps. |

|

|

|

|

| ||

Machine howls on startup. | 1. | Chip deflector too close to the | 1. | Move chip deflector back 1/8" to 1/4" from the cutterhead. | ||

|

|

|

| cutterhead. |

|

|

|

|

|

|

| ||

Table moves down while | 1. | Knives dull. | 1. | Replace knives. | ||

cutting. |

| 2. | Cutterhead is not locked. | 2. | Tighten cutterhead lock knobs. | |

|

|

|

|

|

|

|

G0550/G0551 15" Planer |