Tailstock

The tailstock is typically used to support long workpieces at the side opposite the spindle, using a live or dead center. It can also hold a tapered drill bit (or a drill chuck with a regular drill bit) for boring holes. Unlike boring done with a drill press where the workpiece is fixed and the drill bit rotates, the drill bit in a tailstock remains station- ary while the workpiece is rotated by the spindle.

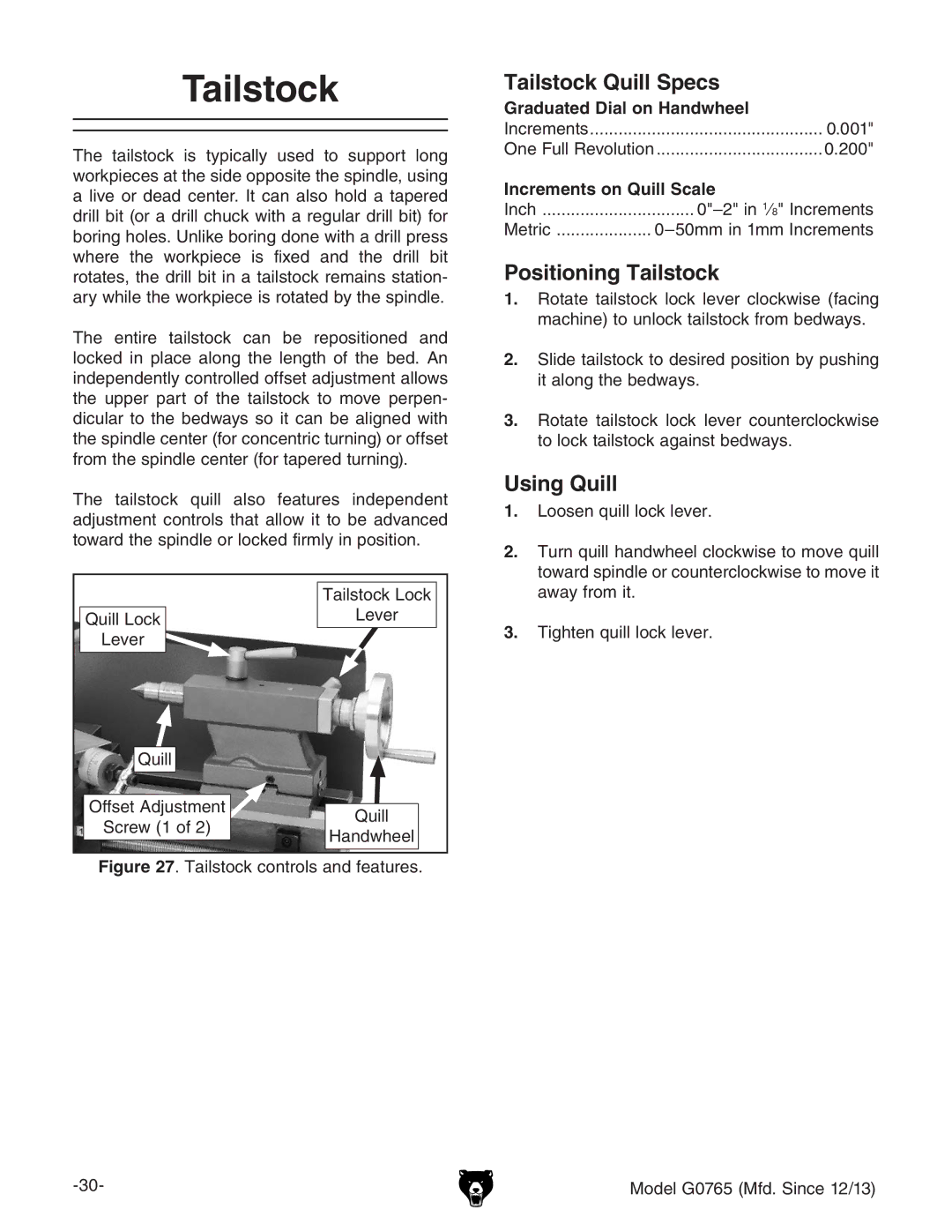

The entire tailstock can be repositioned and locked in place along the length of the bed. An independently controlled offset adjustment allows the upper part of the tailstock to move perpen- dicular to the bedways so it can be aligned with the spindle center (for concentric turning) or offset from the spindle center (for tapered turning).

The tailstock quill also features independent adjustment controls that allow it to be advanced toward the spindle or locked firmly in position.

| Tailstock Lock | |

Quill Lock | Lever | |

Lever |

| |

Quill |

| |

Offset Adjustment | Quill | |

Screw (1 of 2) | ||

Handwheel | ||

|

Figure 27. Tailstock controls and features.

Tailstock Quill Specs

Graduated Dial on Handwheel

Increments | 0.001" |

One Full Revolution | 0.200" |

Increments on Quill Scale | |

Inch | |

Metric | |

Positioning Tailstock

1.Rotate tailstock lock lever clockwise (facing machine) to unlock tailstock from bedways.

2.Slide tailstock to desired position by pushing it along the bedways.

3.Rotate tailstock lock lever counterclockwise to lock tailstock against bedways.

Using Quill

1.Loosen quill lock lever.

2.Turn quill handwheel clockwise to move quill toward spindle or counterclockwise to move it away from it.

3.Tighten quill lock lever.

Model G0765 (Mfd. Since 12/13)