Chuck Installation

To ensure accurate work, it is extremely important to make sure the spindle nose and chuck mating surfaces are clean. Even a small amount of lint or debris can affect accuracy.

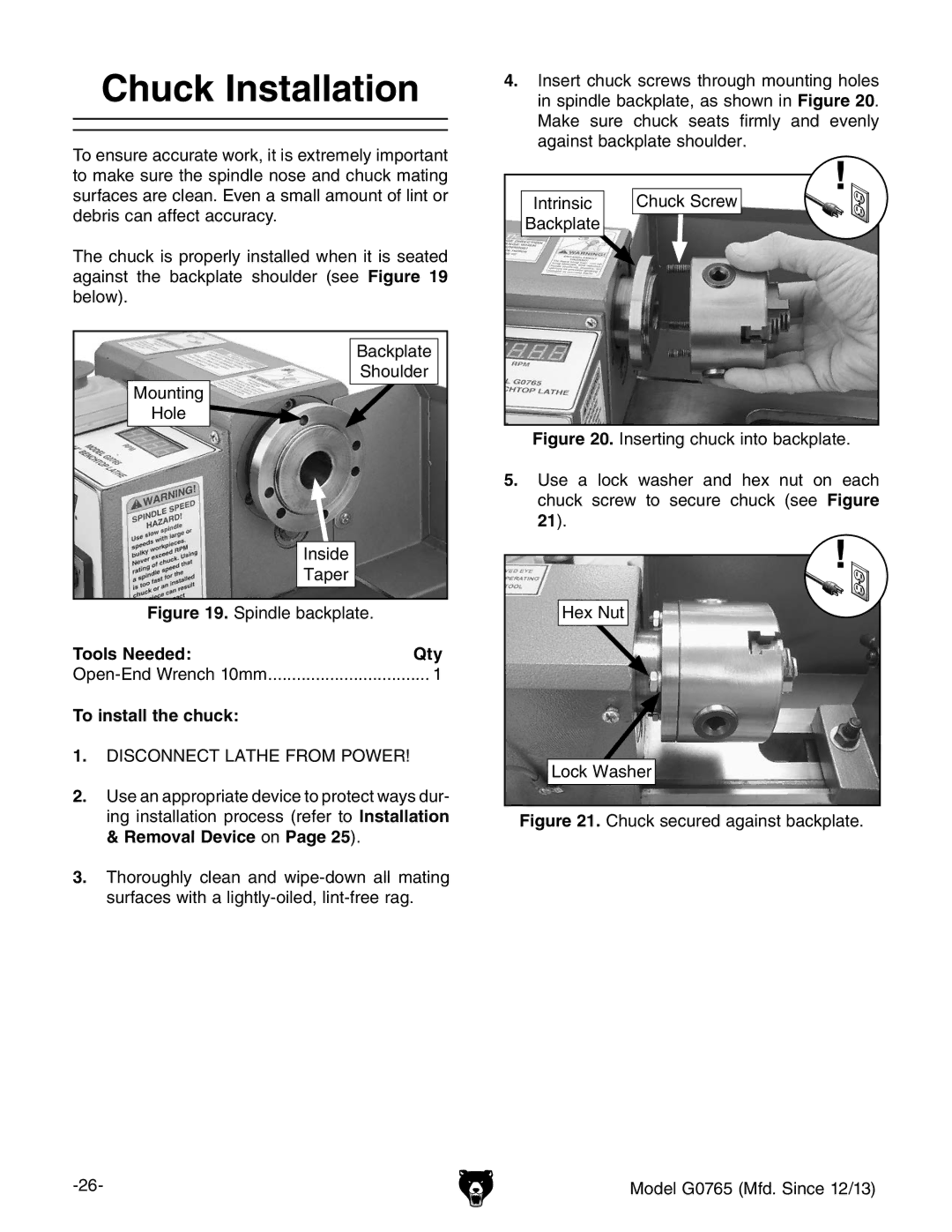

The chuck is properly installed when it is seated against the backplate shoulder (see Figure 19 below).

Backplate

Shoulder

Mounting

Hole

Inside |

|

Taper |

|

Figure 19. Spindle backplate. |

|

Tools Needed: | Qty |

1 | |

To install the chuck: |

|

1.DISCONNECT LATHE FROM POWER!

2.Use an appropriate device to protect ways dur- ing installation process (refer to Installation & Removal Device on Page 25).

3.Thoroughly clean and

4.Insert chuck screws through mounting holes in spindle backplate, as shown in Figure 20. Make sure chuck seats firmly and evenly against backplate shoulder.

Intrinsic | Chuck Screw |

Backplate |

|