Power Feed

The carriage has power feed options for either threading or

To avoid damaging lathe, ALWAYS make sure spindle is completely stopped BEFORE using headstock controls to make changes.

Power Feed Controls

Use the following descriptions and figures to understand the power feed controls.

Before using power feed, you may have to recon- figure the end gears, depending on how they are set up. The lathe comes from the factory with the end gears setup in the standard configuration (refer to End Gears on Page 43). This end gear configuration achieves a fixed feed rate of 0.04 in/ rev. Refer to End Gears on Page 43 for detailed instructions on how to configure the end gears.

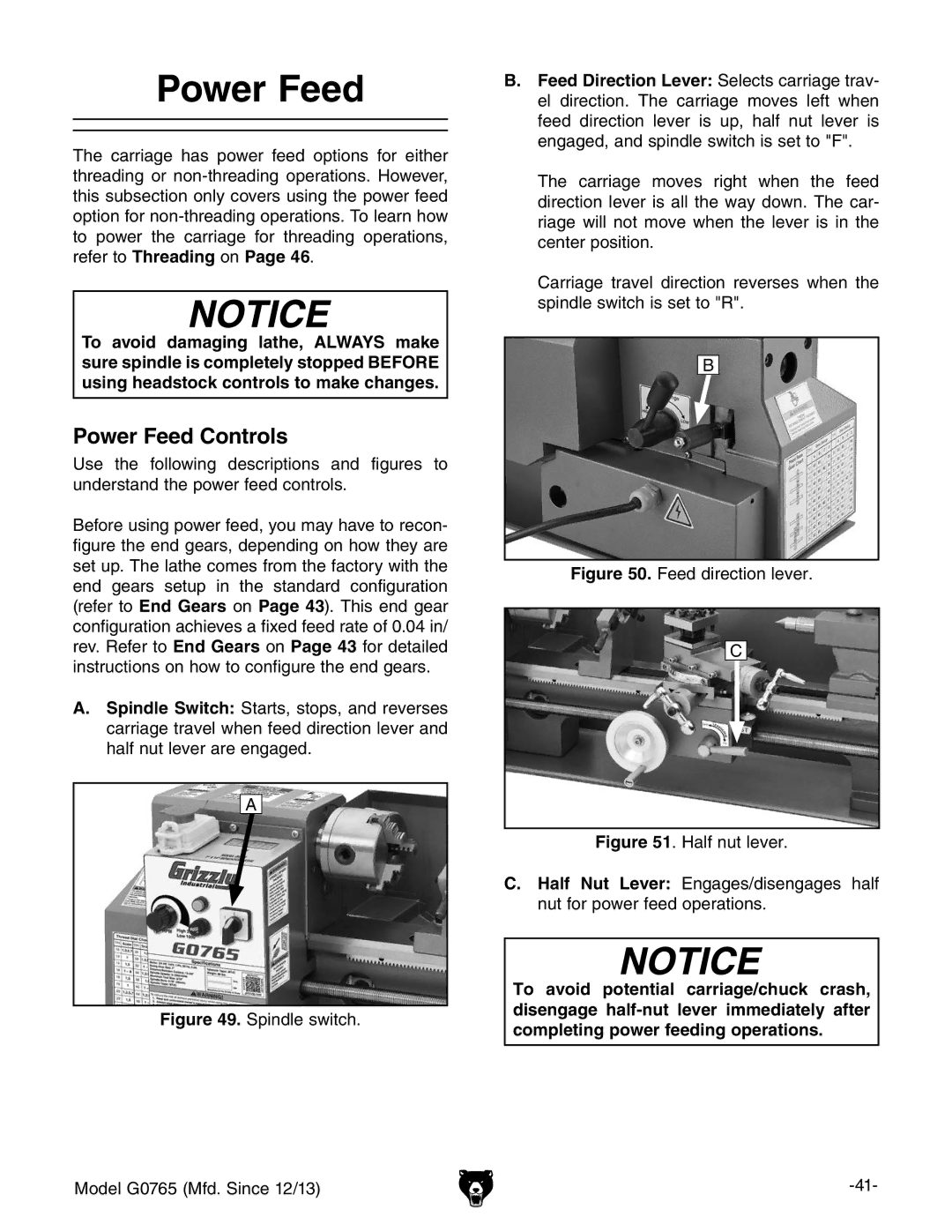

A.Spindle Switch: Starts, stops, and reverses carriage travel when feed direction lever and half nut lever are engaged.

A

Figure 49. Spindle switch.

Model G0765 (Mfd. Since 12/13)

B.Feed Direction Lever: Selects carriage trav- el direction. The carriage moves left when feed direction lever is up, half nut lever is engaged, and spindle switch is set to "F".

The carriage moves right when the feed direction lever is all the way down. The car- riage will not move when the lever is in the center position.

Carriage travel direction reverses when the spindle switch is set to "R".

B

Figure 50. Feed direction lever.

C

Figure 51. Half nut lever.

C.Half Nut Lever: Engages/disengages half nut for power feed operations.

To avoid potential carriage/chuck crash, disengage