Chuck & Faceplate

Mounting

This lathe is equipped with an intrinsic backplate spindle nose. With this type of spindle, a chuck or faceplate is mounted directly to the backplate with hex nuts.

Never use spindle speeds faster than the chuck RPM rating or the safe limits of your workpiece. Excessive spindle speeds greatly increase the risk of the workpiece or chuck being thrown from the machine with deadly force!

This lathe ships with the

The included faceplate has slots for

Installation &

Removal Device

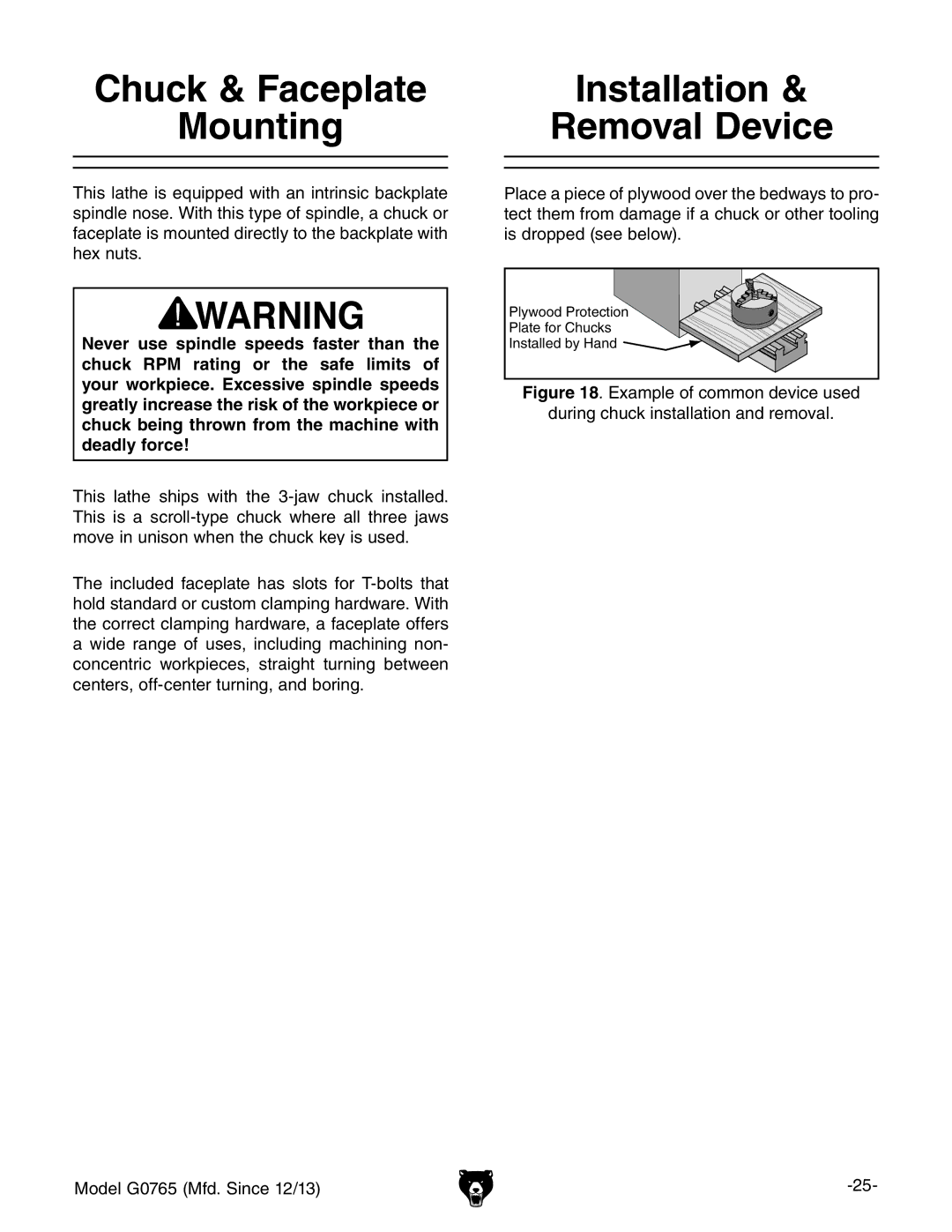

Place a piece of plywood over the bedways to pro- tect them from damage if a chuck or other tooling is dropped (see below).

Plywood Protection |

Plate for Chucks |

Installed by Hand |

Figure 18. Example of common device used

during chuck installation and removal.

Model G0765 (Mfd. Since 12/13) |