Installing Tooling

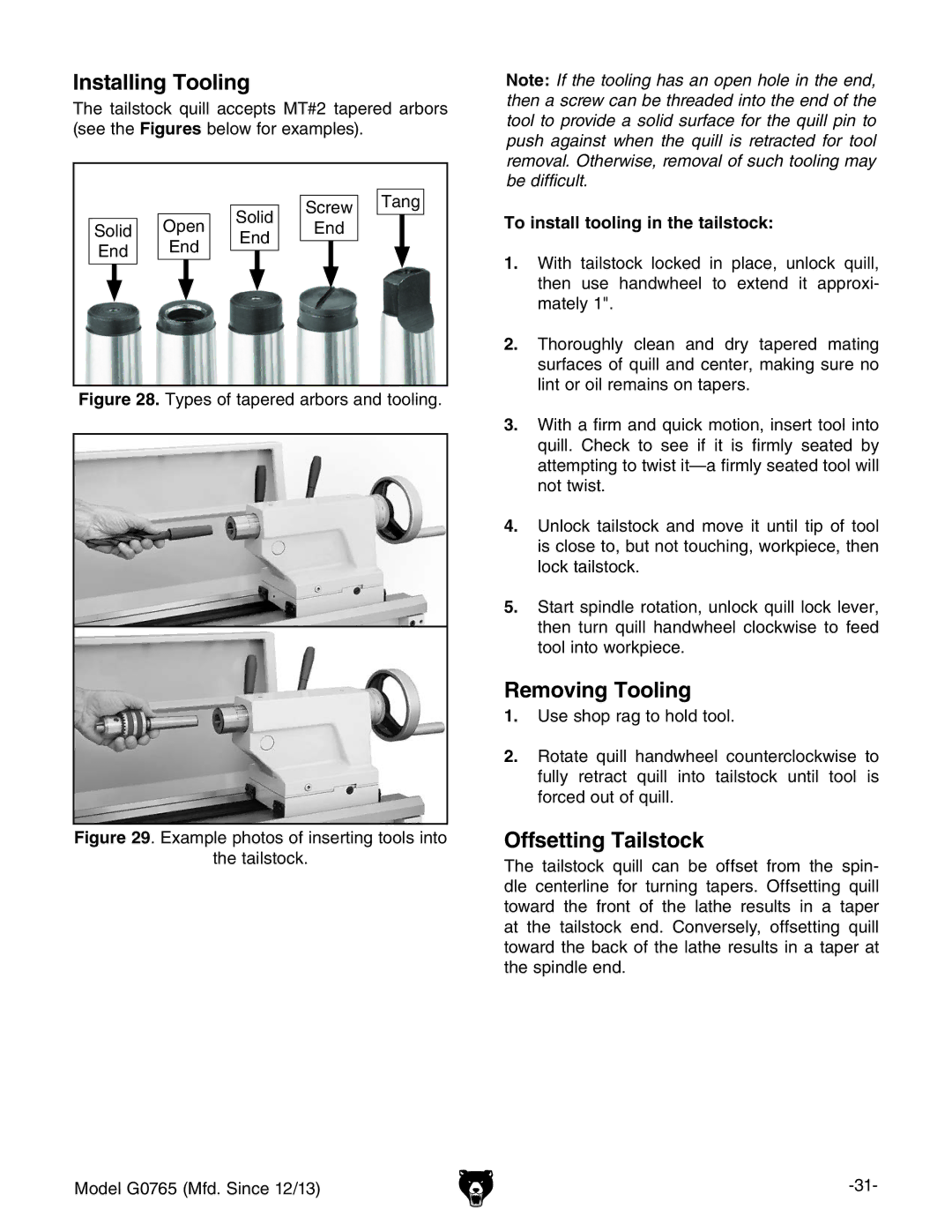

The tailstock quill accepts MT#2 tapered arbors (see the Figures below for examples).

|

|

|

|

|

|

|

|

|

|

|

| Tang |

| |||

|

|

|

|

|

|

|

|

| Screw |

|

|

| ||||

|

|

|

|

|

| Solid |

|

|

|

| ||||||

Solid |

| Open |

|

| End |

|

|

|

|

|

| |||||

|

| End |

|

|

|

|

|

| ||||||||

End |

| End |

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure 28. Types of tapered arbors and tooling.

Figure 29. Example photos of inserting tools into

the tailstock.

Model G0765 (Mfd. Since 12/13)

Note: If the tooling has an open hole in the end, then a screw can be threaded into the end of the tool to provide a solid surface for the quill pin to push against when the quill is retracted for tool removal. Otherwise, removal of such tooling may be difficult.

To install tooling in the tailstock:

1.With tailstock locked in place, unlock quill, then use handwheel to extend it approxi- mately 1".

2.Thoroughly clean and dry tapered mating surfaces of quill and center, making sure no lint or oil remains on tapers.

3.With a firm and quick motion, insert tool into quill. Check to see if it is firmly seated by attempting to twist

4.Unlock tailstock and move it until tip of tool is close to, but not touching, workpiece, then lock tailstock.

5.Start spindle rotation, unlock quill lock lever, then turn quill handwheel clockwise to feed tool into workpiece.

Removing Tooling

1.Use shop rag to hold tool.

2.Rotate quill handwheel counterclockwise to fully retract quill into tailstock until tool is forced out of quill.

Offsetting Tailstock

The tailstock quill can be offset from the spin- dle centerline for turning tapers. Offsetting quill toward the front of the lathe results in a taper at the tailstock end. Conversely, offsetting quill toward the back of the lathe results in a taper at the spindle end.