Timing Belt Tension

& Replacement

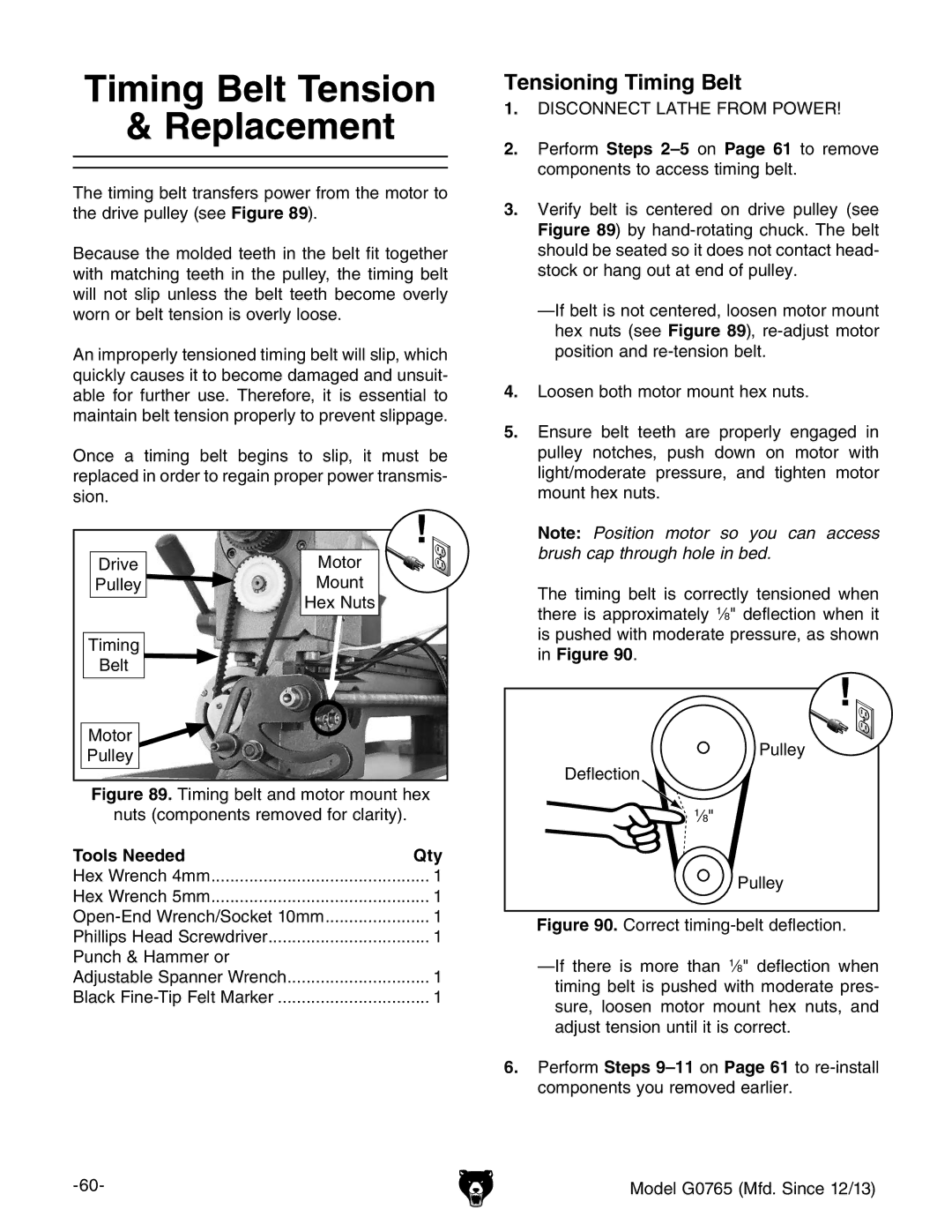

The timing belt transfers power from the motor to the drive pulley (see Figure 89).

Because the molded teeth in the belt fit together with matching teeth in the pulley, the timing belt will not slip unless the belt teeth become overly worn or belt tension is overly loose.

An improperly tensioned timing belt will slip, which quickly causes it to become damaged and unsuit- able for further use. Therefore, it is essential to maintain belt tension properly to prevent slippage.

Once a timing belt begins to slip, it must be replaced in order to regain proper power transmis- sion.

| Drive |

| Motor |

| Pulley |

| Mount |

|

|

| Hex Nuts |

|

|

| |

|

|

|

|

|

|

|

|

Timing |

|

| |

| Belt |

|

|

|

|

|

|

Motor

Pulley

Figure 89. Timing belt and motor mount hex

nuts (components removed for clarity).

Tools Needed | Qty |

Hex Wrench 4mm | 1 |

Hex Wrench 5mm | 1 |

1 | |

Phillips Head Screwdriver | 1 |

Punch & Hammer or |

|

Adjustable Spanner Wrench | 1 |

Black | 1 |

Tensioning Timing Belt

1.DISCONNECT LATHE FROM POWER!

2.Perform Steps

3.Verify belt is centered on drive pulley (see Figure 89) by

4.Loosen both motor mount hex nuts.

5.Ensure belt teeth are properly engaged in pulley notches, push down on motor with light/moderate pressure, and tighten motor mount hex nuts.

Note: Position motor so you can access brush cap through hole in bed.

The timing belt is correctly tensioned when there is approximately 1⁄8" deflection when it is pushed with moderate pressure, as shown in Figure 90.

Pulley

Deflection

1⁄8"

Pulley

Figure 90. Correct timing-belt deflection.

—If there is more than 1⁄8" deflection when timing belt is pushed with moderate pres- sure, loosen motor mount hex nuts, and adjust tension until it is correct.

6.Perform Steps 9–11 on Page 61 to re-install components you removed earlier.

Model G0765 (Mfd. Since 12/13) |