Gib Adjustment

The goal of adjusting the gib screws is to remove sloppiness or "play" from the ways without over- adjusting them to the point where they become stiff and difficult to move.

In general, loose gibs cause poor finishes and tool chatter; however,

The gib adjustment process usually requires some

Clean and lubricate the ways before beginning any adjustments. Refer to Lubrication on Page 51 for instructions and lubricant specifications.

Tools Needed | Qty |

................................... 1 | |

Hex Wrench 3mm | 1 |

To adjust cross slide and compound slide gibs:

1.DISCONNECT LATHE FROM POWER!

2.Loosen three hex nuts on side of cross slide or compound slide (see Figures

Cross Slide

Adjustment

Fasteners

Figure 82. Cross slide gib adjustment hex nuts

and cap screws.

Model G0765 (Mfd. Since 12/13)

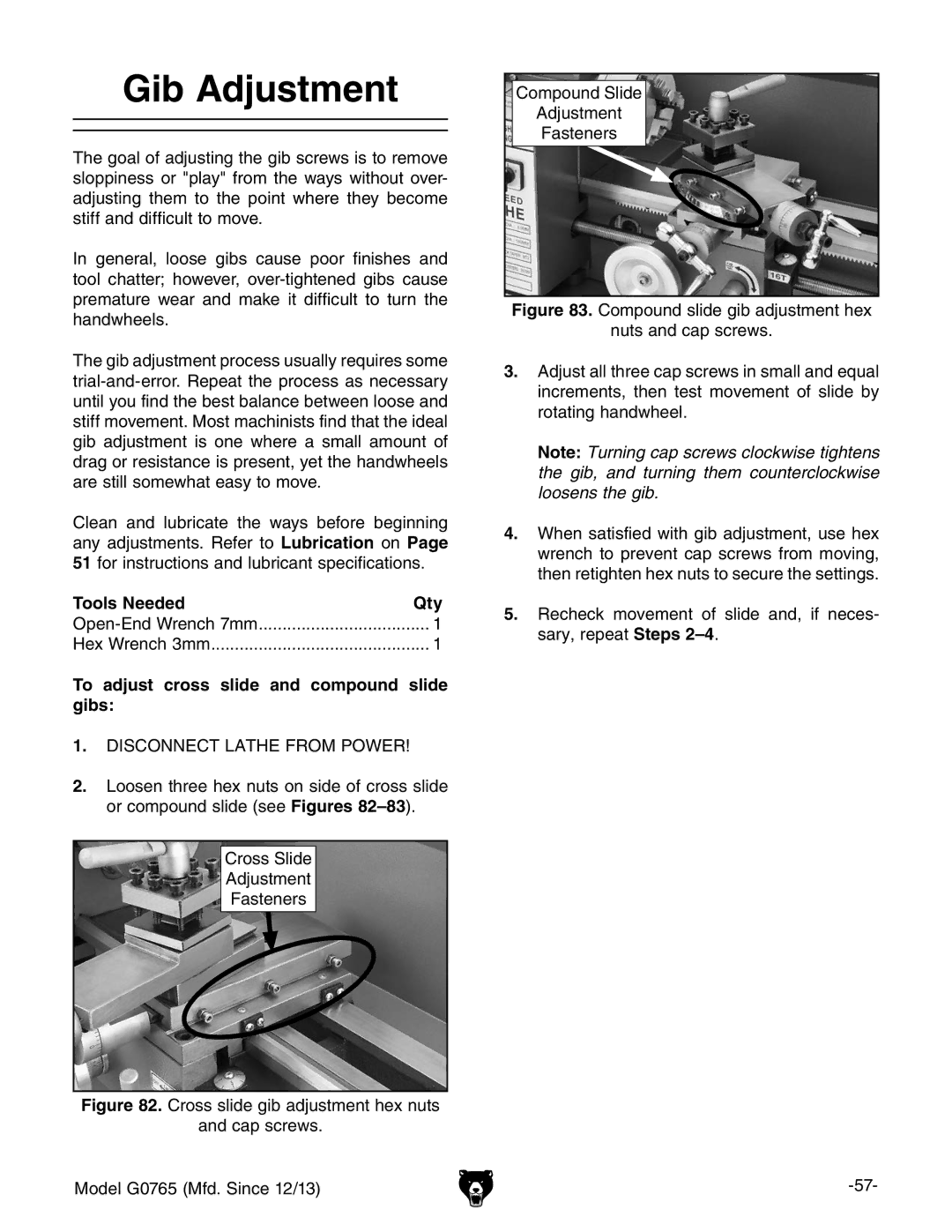

Compound Slide

Adjustment

Fasteners

Figure 83. Compound slide gib adjustment hex

nuts and cap screws.

3.Adjust all three cap screws in small and equal increments, then test movement of slide by rotating handwheel.

Note: Turning cap screws clockwise tightens the gib, and turning them counterclockwise loosens the gib.