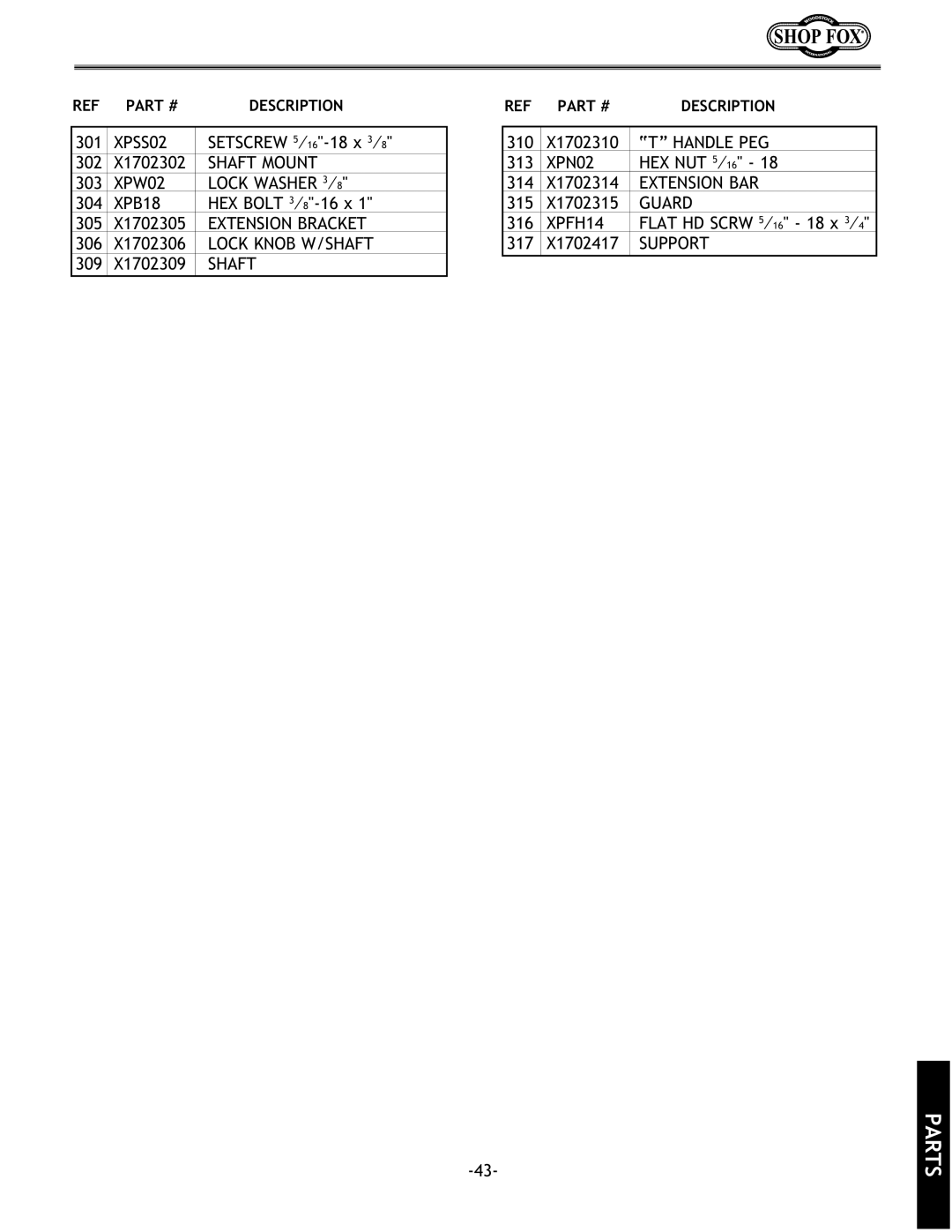

REF | PART # | DESCRIPTION | |

|

|

|

|

301 | XPSS02 | SETSCREW | |

302 | X1702302 | SHAFT MOUNT |

|

303 | XPW02 | LOCK WASHER 3⁄8" |

|

304 | XPB18 | HEX BOLT |

|

305 | X1702305 | EXTENSION BRACKET |

|

306 | X1702306 | LOCK KNOB W/SHAFT | |

309 | X1702309 | SHAFT | |

REF | PART # | DESCRIPTION |

|

|

|

310 | X1702310 | “T” HANDLE PEG |

313 | XPN02 | HEX NUT 5⁄16" - 18 |

314 | X1702314 | EXTENSION BAR |

315 | X1702315 | GUARD |

316 | XPFH14 | FLAT HD SCRW 5⁄16" - 18 x 3⁄4" |

317 | X1702417 | SUPPORT |