Cutter Installation

Always follow the cutter manufacturer recommendations; however, if not available use the list below with your particular cutting needs in mind to help select the correct cutter, spindle, and RPM. Then install your cutter as outlined.

a)Choose Cutter Profile and Cutter:

To help select the correct cutter, you can go online to select your cutter, bushings, and rub collars.

•For shaper cutter profile selection go to www.romancarbide.com and select the applicable cutter.

b)Choose Cutter Height and Spindle Size:

Use these general specifications to help select cutter and spindle size.

| • For the 1⁄2" diameter spindle, the | ||

| maximum safe cutter height used with | ||

| washers, | ||

| lock nuts installed is 2". |

|

|

| • For the 3⁄4" diameter spindle, the | ||

| maximum safe cutter height with | ||

| washers, | ||

| lock nuts installed is 2 1⁄2". |

| |

| • For the 1" diameter | spindle, | the |

| maximum safe cutter height with | ||

| washers, | ||

| lock nuts installed is 2 1⁄4". |

| |

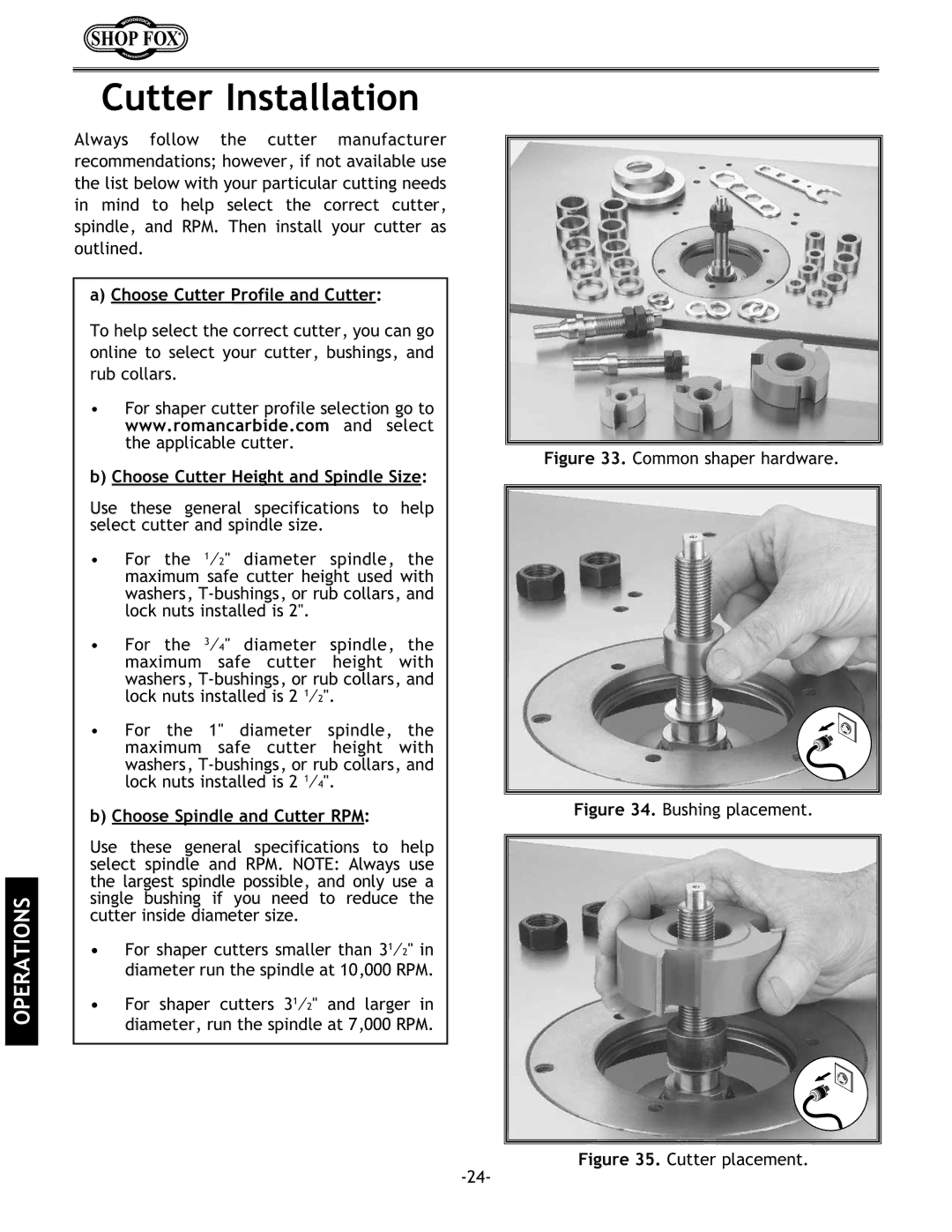

| b) Choose Spindle and Cutter RPM: |

| |

| Use these general specifications to help | ||

| select spindle and RPM. NOTE: Always use | ||

| the largest spindle possible, and only use a | ||

| |||

OPERATIONS | single bushing if you need | to reduce | the |

cutter inside diameter size. |

|

| |

|

|

| |

| • For shaper cutters smaller than 31⁄2" in | ||

| diameter run the spindle at 10,000 RPM. | ||

| • For shaper cutters 31⁄2" and larger in | ||

| diameter, run the spindle at 7,000 RPM. | ||

|

|

|

|