ASSEMBLY

Fence Facing

Fence facing can be custom made for special

To install the fence facing, do these steps:

1.Using

2.For custom fence facing, make sure the screw heads are countersunk completely below the surface of the fence face.

Safety Guard

Always use a safety guard whenever possible. The safety guard improve shaping safety.

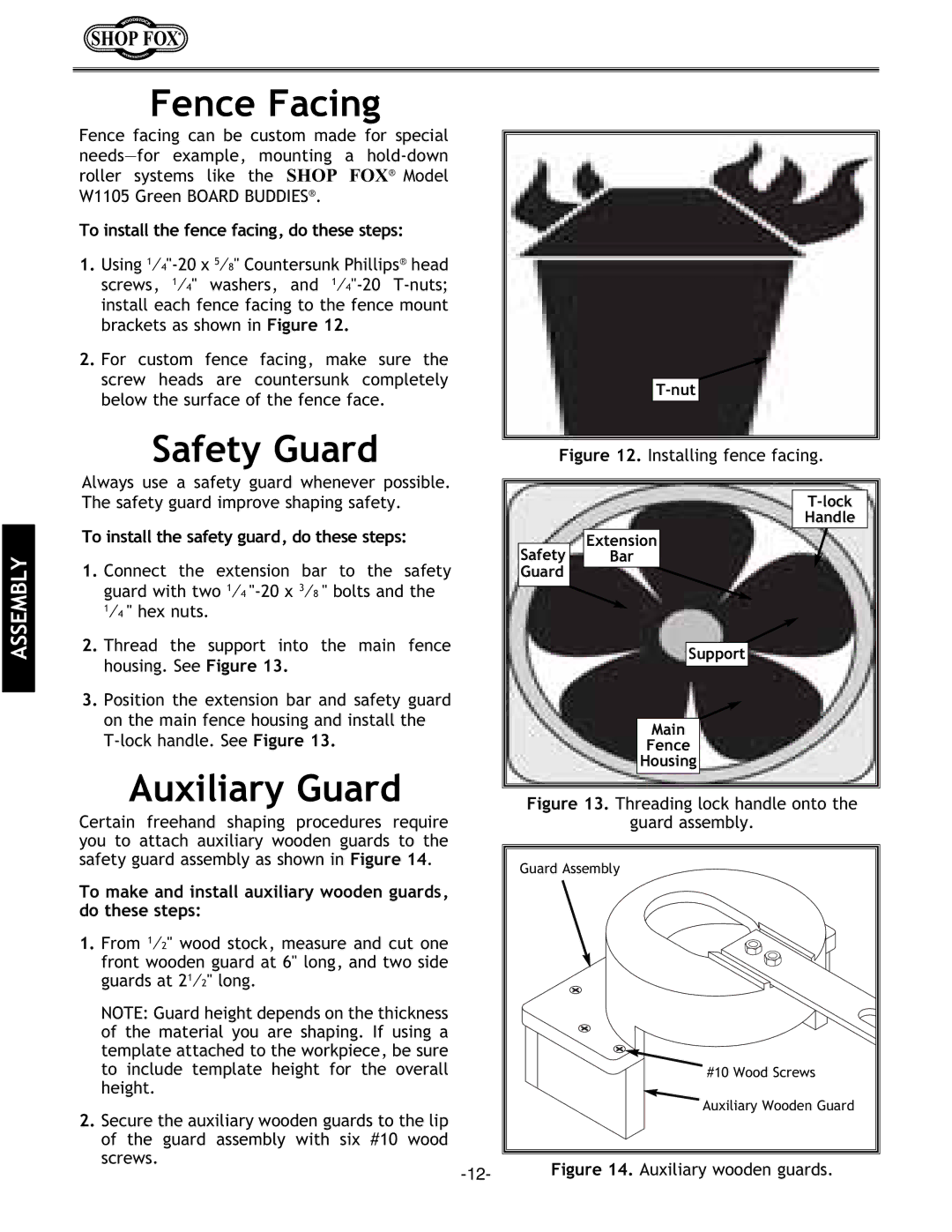

To install the safety guard, do these steps:

1.Connect the extension bar to the safety guard with two 1⁄4

1⁄4 " hex nuts.

2.Thread the support into the main fence housing. See Figure 13.

3.Position the extension bar and safety guard on the main fence housing and install the

Auxiliary Guard

Certain freehand shaping procedures require you to attach auxiliary wooden guards to the safety guard assembly as shown in Figure 14.

To make and install auxiliary wooden guards, do these steps:

1.From 1⁄2" wood stock, measure and cut one front wooden guard at 6" long, and two side guards at 21⁄2" long.

NOTE: Guard height depends on the thickness of the material you are shaping. If using a template attached to the workpiece, be sure to include template height for the overall height.

2.Secure the auxiliary wooden guards to the lip of the guard assembly with six #10 wood screws.

Figure 12. Installing fence facing.

| |

| Handle |

Safety | Extension |

Bar | |

Guard |

|

| Support |

| Main |

| Fence |

| Housing |

Figure 13. Threading lock handle onto the

guard assembly.

Guard Assembly |

#10 Wood Screws |

Auxiliary Wooden Guard |