Air Handler Coils

There are a wide variety of coil types to meet the load requirements of conditioned spaces. Heatcraft’s four coil types are: water, direct expansion, heat reclaim and steam coils. All standard coils have copper tubes and aluminum fins and a heavy gauge mill galvanized steel casing. Staggered tube designs increase air turbulence and improve coil performance. The plate type, die formed, corrugated fin design provides optimum strength. The fin design also enhances air turbulence for peak performance. Each fin has die formed,

Water

Coils

Direct Expansion Coils

Select direct expansion coils from 3, 4, 5, 6, or 8 row coil depth options. All direct expansion coils offer five fin densities (6, 8, 10, 12, or 14 FPI). Specify either 1/2" (Type A) or 5/8" (Type 5) tube diameters. Each coil has a brass, sweat connection type distributor and copper suction header. Distributor leads of equal length work for equal refrigerant distribution to all the circuits. Working with Heatcraft software or your representative, select from a among variety of circuit designs. Heatcraft has an optimum design to deliver the proper refrigerant pressure drop for your conditions. Specify multiple distributors for face split or row split control of the coil.

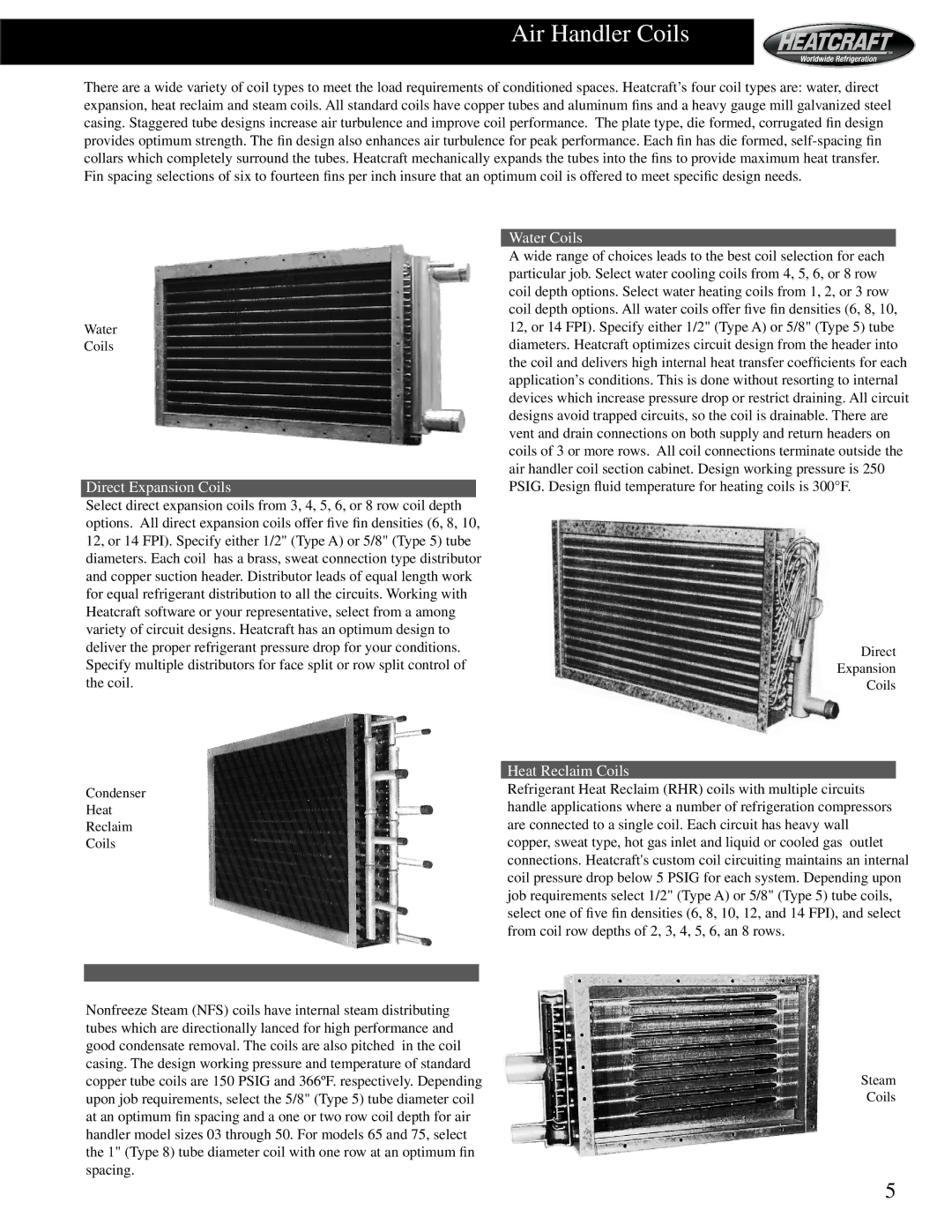

Condenser

Heat

Reclaim

Coils

Nonfreeze Steam (NFS) coils have internal steam distributing tubes which are directionally lanced for high performance and good condensate removal. The coils are also pitched in the coil casing. The design working pressure and temperature of standard copper tube coils are 150 PSIG and 366ºF. respectively. Depending upon job requirements, select the 5/8" (Type 5) tube diameter coil at an optimum fin spacing and a one or two row coil depth for air handler model sizes 03 through 50. For models 65 and 75, select the 1" (Type 8) tube diameter coil with one row at an optimum fin spacing.

Water Coils

A wide range of choices leads to the best coil selection for each particular job. Select water cooling coils from 4, 5, 6, or 8 row coil depth options. Select water heating coils from 1, 2, or 3 row coil depth options. All water coils offer five fin densities (6, 8, 10, 12, or 14 FPI). Specify either 1/2" (Type A) or 5/8" (Type 5) tube diameters. Heatcraft optimizes circuit design from the header into the coil and delivers high internal heat transfer coefficients for each application’s conditions. This is done without resorting to internal devices which increase pressure drop or restrict draining. All circuit designs avoid trapped circuits, so the coil is drainable. There are vent and drain connections on both supply and return headers on coils of 3 or more rows. All coil connections terminate outside the air handler coil section cabinet. Design working pressure is 250 PSIG. Design fluid temperature for heating coils is 300°F.

Direct

Expansion

Coils

Heat Reclaim Coils

Refrigerant Heat Reclaim (RHR) coils with multiple circuits handle applications where a number of refrigeration compressors are connected to a single coil. Each circuit has heavy wall copper, sweat type, hot gas inlet and liquid or cooled gas outlet connections. Heatcraft's custom coil circuiting maintains an internal coil pressure drop below 5 PSIG for each system. Depending upon job requirements select 1/2" (Type A) or 5/8" (Type 5) tube coils, select one of five fin densities (6, 8, 10, 12, and 14 FPI), and select from coil row depths of 2, 3, 4, 5, 6, an 8 rows.

Steam

Coils

5