Air Handler Selection

1.Air handler selections vary with each application. Use the index below to find Heatcraft Products air handler performance tables for:

•Standard comfort cooling (either direct expansion or chilled water)

•Heating (either steam or hot water, either make up air or return air)

•Supermarket air conditioning (direct expansion refrigerant)

•Heat reclaim (coil performance, refrigerant condenser, typically supermarket)

2.The air handler performance tables give ARI ratings for the specific applications, conditions and coils listed. All performance tables (except reclaim) rate: 10 FPI coils at 500 FPM coil air velocity.

To select air handlers for other applications, conditions, or components:

•Call your representative. With your representative, you can have specific

computer selected coils rated for your job conditions.

•Use tables on pages 21 to 23 for estimates of coil performance at various conditions.

3.See page 12, step 5 to calculate total static pressure. Consult fan tables, pages 24 to 29 and select fan motor.

4.Heatcraft builds each air handler to your components specifications. Please specify the following as needed with your order:

•CFM

•External or total static pressure

•Motor HP, motor type, motor voltage, motor location (left hand or right hand)

•Describe coils or specify with Heatcraft Products model numbers.

Coil description can include:

Rows, FPI, refrigerant, design capacity (BTUH),

Number of circuits, coil location inside air handler (preheat, reheat, etc.)

Location of coil connections (left hand or right hand)

•Filter sections and filter types

•Vibration isolators

5.Go to page 12 for air handler selection example.

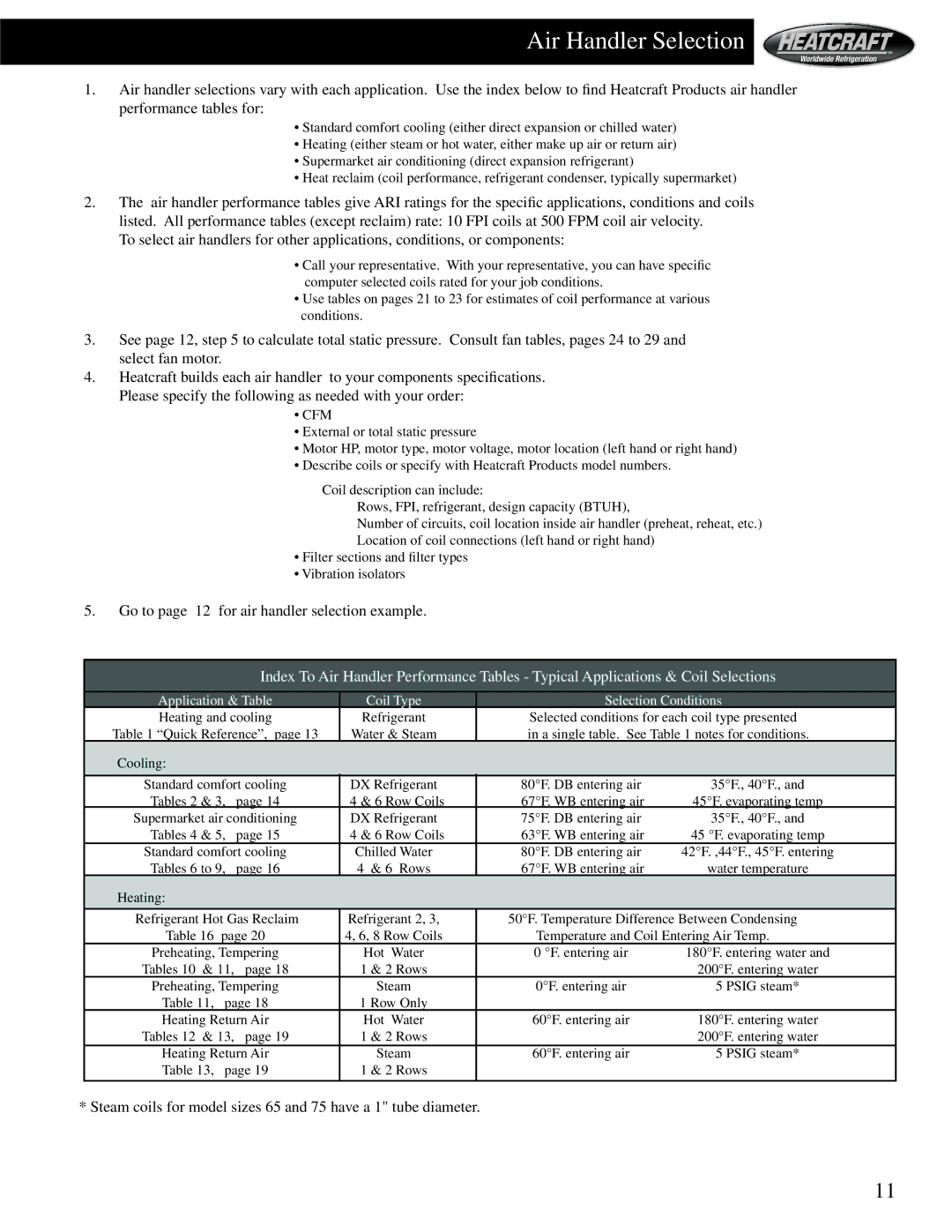

Index To Air Handler Performance Tables - Typical Applications & Coil Selections

Application & Table | Coil Type | Selection Conditions | |||

Heating and cooling | Refrigerant | Selected conditions for each coil type presented | |||

Table 1 “Quick Reference”, page 13 | Water & Steam | in a single table. See Table 1 notes for conditions. | |||

Cooling: |

|

|

|

|

|

Standard comfort cooling | DX Refrigerant | 80°F. DB entering air | 35°F., 40°F., and | ||

Tables 2 & 3, | page 14 | 4 & 6 Row Coils | 67°F. WB entering air | 45°F. evaporating temp | |

Supermarket air conditioning | DX Refrigerant | 75°F. DB entering air | 35°F., 40°F., and | ||

Tables 4 & 5, | page 15 | 4 & 6 Row Coils | 63°F. WB entering air | 45 °F. evaporating temp | |

Standard comfort cooling | Chilled Water | 80°F. DB entering air | 42°F. ,44°F., 45°F. entering | ||

Tables 6 to 9, | page 16 | 4 & 6 Rows | 67°F. WB entering air | water temperature | |

Heating: |

|

|

|

|

|

Refrigerant Hot Gas Reclaim | Refrigerant 2, 3, | 50°F. Temperature Difference Between Condensing | |||

Table 16 page 20 | 4, 6, 8 Row Coils | Temperature and Coil Entering Air Temp. | |||

Preheating, Tempering | Hot Water | 0 °F. entering air | 180°F. entering water and | ||

Tables 10 & 11, | page 18 | 1 & 2 Rows |

| 200°F. entering water | |

Preheating, Tempering | Steam | 0°F. entering air | 5 PSIG steam* | ||

Table 11, | page 18 | 1 Row Only |

|

| |

Heating Return Air | Hot Water | 60°F. entering air | 180°F. entering water | ||

Tables 12 & 13, | page 19 | 1 & 2 Rows |

| 200°F. entering water | |

Heating Return Air | Steam | 60°F. entering air | 5 PSIG steam* | ||

Table 13, | page 19 | 1 & 2 Rows |

|

| |

|

|

|

|

|

|

* Steam coils for model sizes 65 and 75 have a 1" tube diameter.

11