English

SERVICE AND REPAIRS

![]() WARNING

WARNING

•

•

Only service personnel trained by Hitachi, distributor or em- ployer shall repair the Tool.

Use only Hitachi parts supplied or recommended by Hitachi for repair.

All quality Tools will eventually require servicing or replacement of parts because of wear from normal use.

In order to achieve the optimal performance of the NT50AF Pneu‑ matic Flooring Nailer and N5009AF Pneumatic Flooring Stapler preventative maintenance is recommended.

NOTE:

Specifications are subject to change without any obligation on the part of HITACHI.

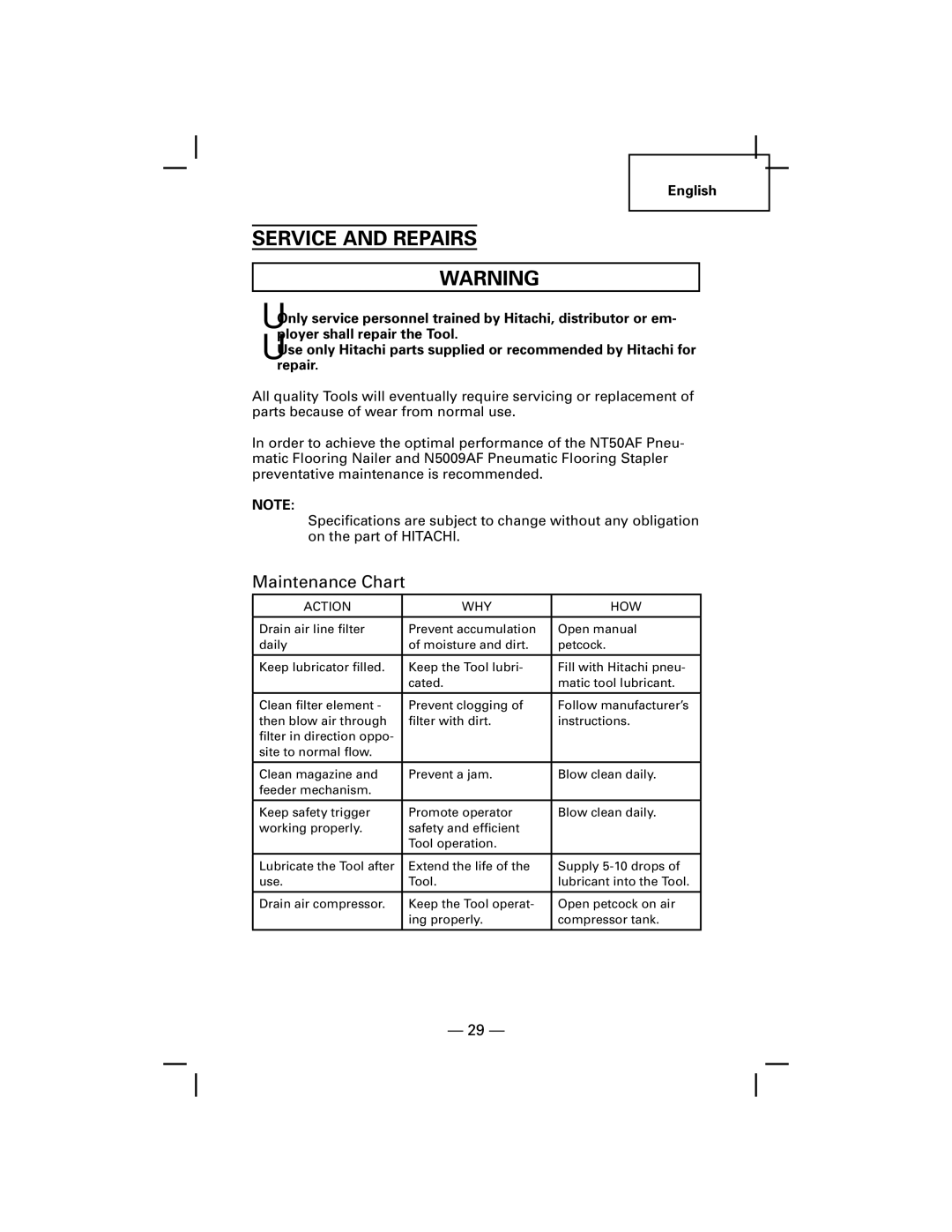

Maintenance Chart

ACTION | WHY | HOW |

|

|

|

Drain air line filter | Prevent accumulation | Open manual |

daily | of moisture and dirt. | petcock. |

|

|

|

Keep lubricator filled. | Keep the Tool lubri‑ | Fill with Hitachi pneu‑ |

| cated. | matic tool lubricant. |

|

|

|

Clean filter element - | Prevent clogging of | Follow manufacturer’s |

then blow air through | filter with dirt. | instructions. |

filter in direction oppo‑ |

|

|

site to normal flow. |

|

|

|

|

|

Clean magazine and | Prevent a jam. | Blow clean daily. |

feeder mechanism. |

|

|

|

|

|

Keep safety trigger | Promote operator | Blow clean daily. |

working properly. | safety and efficient |

|

| Tool operation. |

|

|

|

|

Lubricate the Tool after | Extend the life of the | Supply |

use. | Tool. | lubricant into the Tool. |

|

|

|

Drain air compressor. | Keep the Tool operat‑ | Open petcock on air |

| ing properly. | compressor tank. |

|

|

|

— 29 —