English

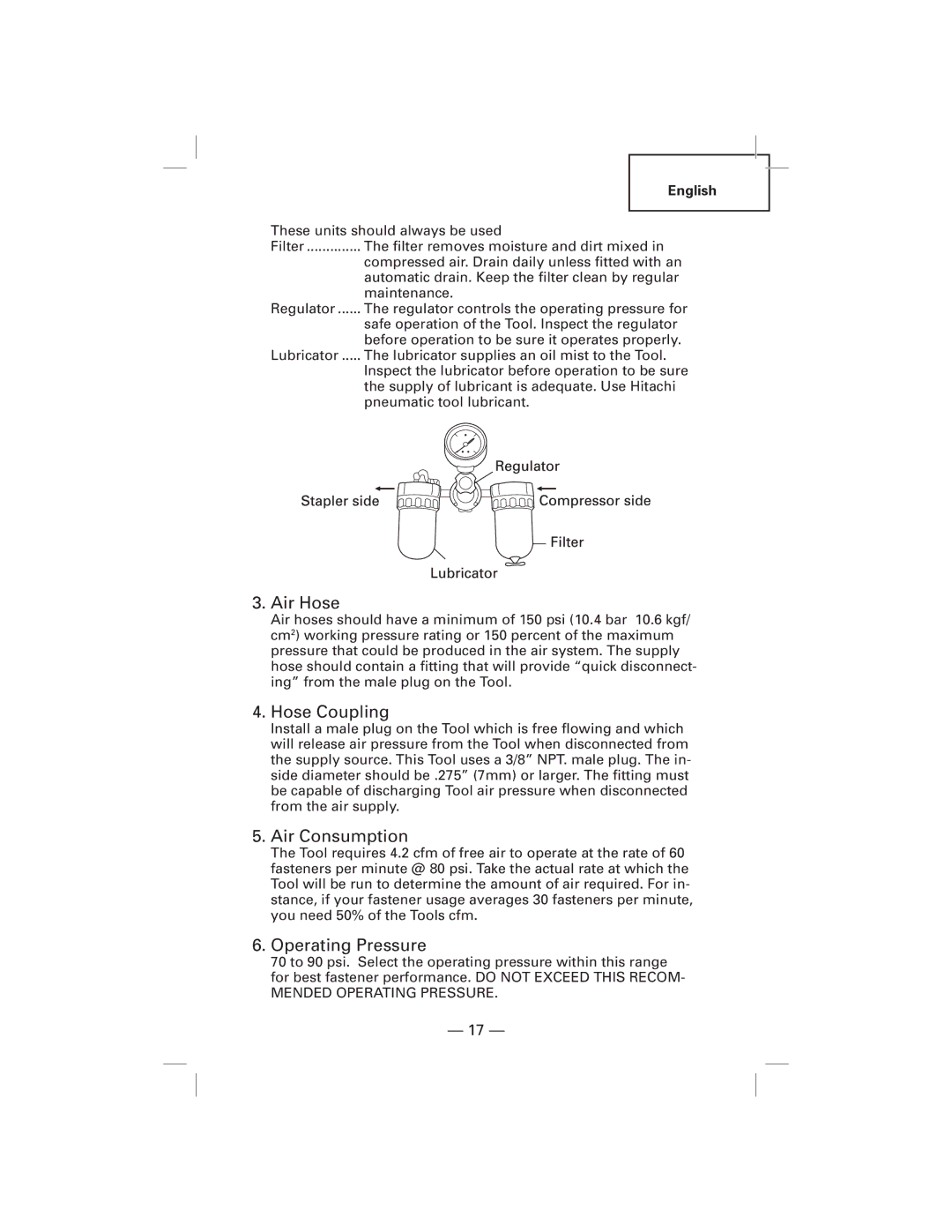

These units should always be used

Filter............... The filter removes moisture and dirt mixed in

compressed air. Drain daily unless fitted with an automatic drain. Keep the filter clean by regular maintenance.

Regulator....... The regulator controls the operating pressure for

safe operation of the Tool. Inspect the regulator before operation to be sure it operates properly.

Lubricator...... The lubricator supplies an oil mist to the Tool.

Inspect the lubricator before operation to be sure the supply of lubricant is adequate. Use Hitachi pneumatic tool lubricant.

3. Air Hose

Air hoses should have a minimum of 150 psi (10.4 bar 10.6 kgf/ cm2) working pressure rating or 150 percent of the maximum pressure that could be produced in the air system. The supply hose should contain a fitting that will provide “quick disconnect‑ ing” from the male plug on the Tool.

4. Hose Coupling

Install a male plug on the Tool which is free flowing and which will release air pressure from the Tool when disconnected from the supply source. This Tool uses a 3/8” NPT. male plug. The in‑ side diameter should be .275” (7mm) or larger. The fitting must be capable of discharging Tool air pressure when disconnected from the air supply.

5. Air Consumption

The Tool requires 4.2 cfm of free air to operate at the rate of 60 fasteners per minute @ 80 psi. Take the actual rate at which the Tool will be run to determine the amount of air required. For in‑ stance, if your fastener usage averages 30 fasteners per minute, you need 50% of the Tools cfm.

6. Operating Pressure

70 to 90 psi. Select the operating pressure within this range for best fastener performance. DO NOT EXCEED THIS RECOM‑

MENDED OPERATING PRESSURE.

— 17 —