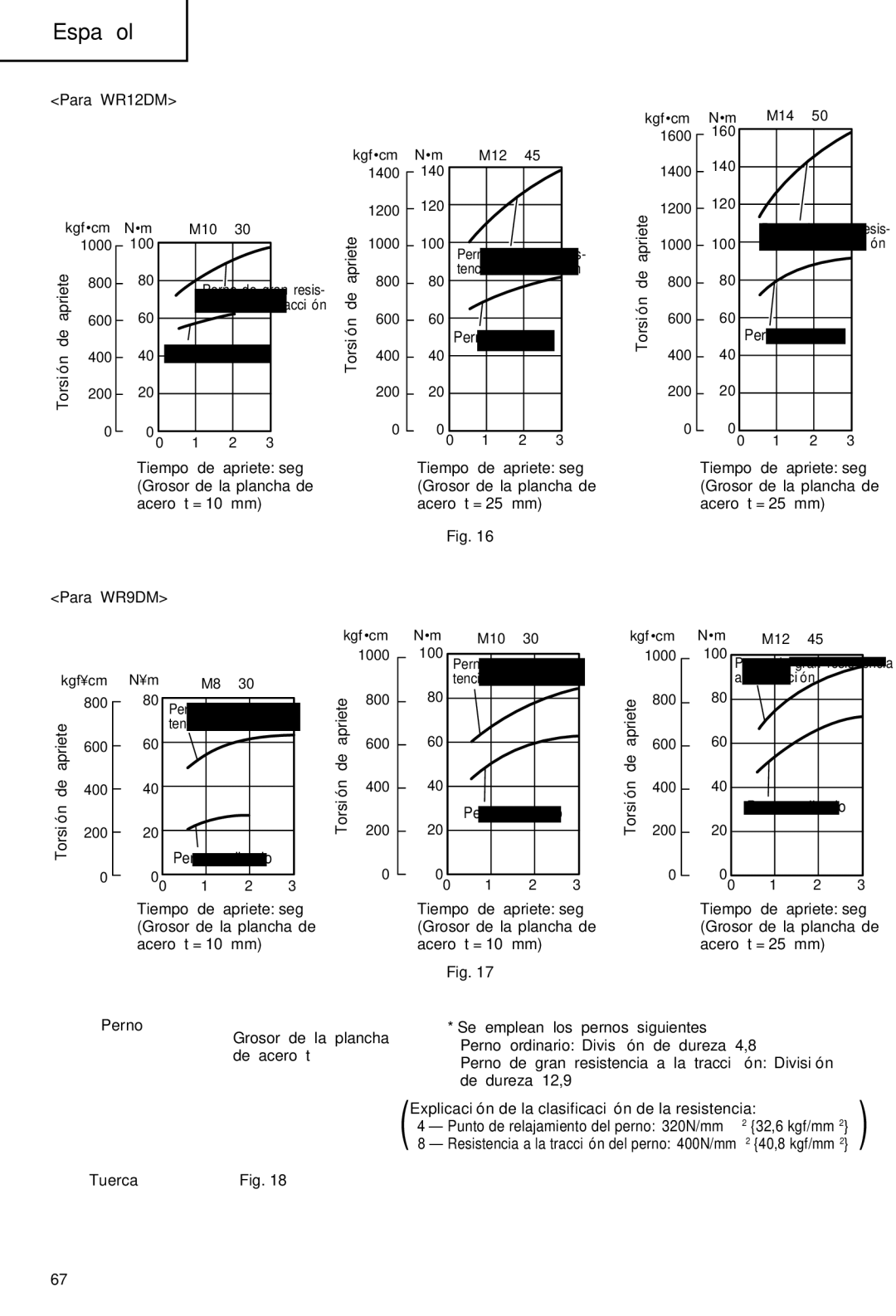

WR 9DM, WR 12DM specifications

The Hitachi WR 12DM and WR 9DM are professional grade power tools designed to meet the needs of both DIY enthusiasts and construction professionals. These powerful models stand out in the market with their innovative features, advanced technology, and ergonomic design, making them ideal for a variety of applications such as drilling, fastening, and woodworking.The Hitachi WR 12DM is equipped with a robust 12V motor that delivers impressive torque and speed, enabling it to tackle a wide range of fastening tasks with ease. It features a maximum torque of 130Nm, making it suitable for heavy-duty applications. The compact and lightweight design of the tool allows for easy maneuverability in tight spaces, reducing operator fatigue during extended use.

One of the standout technologies of the WR 12DM is its brushless motor, which provides several advantages over traditional brushed motors. This technology ensures longer runtime, increased efficiency, and reduced maintenance, as there are fewer moving parts that can wear out over time. Additionally, the integrated Electronic Speed Control allows for variable speeds, giving users the flexibility to adjust performance settings according to the demands of the task at hand.

On the other hand, the Hitachi WR 9DM offers a more compact solution, equipped with a 9V motor for lighter tasks. With a maximum torque of 90Nm, it is perfect for smaller projects and general maintenance work. The design is optimized for ease of handling, ensuring that it’s not only efficient but also comfortable to use for extended periods.

Both models emphasize user safety and convenience. They come with a built-in LED light that illuminates the workspace, ensuring visibility in low-light conditions. The ergonomic grip provides a comfortable hold, reducing stress on the hands during operation. Furthermore, both tools feature a keyless chuck for quick and easy bit changes, enhancing overall productivity.

The Hitachi WR series also showcases an excellent battery system, with Li-ion technology offering longer battery life and faster charging times. These features collectively make the WR 12DM and WR 9DM reliable choices for professionals looking for efficiency, power, and innovation in their tools. Together, they demonstrate Hitachi’s commitment to quality and performance in the power tool market.