MAINTENANCE

WARNING: HOT OIL AND PARTS CAN CAUSE BURNS. USE CARE WHEN OPERATING, CLEANING AND SERVICING THE FRYER.

WARNING: SPILLING HOT FRYING COMPOUND CAN CAUSE SEVERE BURNS. DO NOT MOVE FRYER WITHOUT DRAINING ALL FRYING COMPOUND FROM THE TANK.

WARNING: UNPLUG ELECTRICAL POWER SUPPLY BEFORE PERFORMING ANY MAINTENANCE.

LID O-RING SEAL REPLACEMENT

Removal and replacement instructions for the lid

OTHER O-RING SEAL REPLACEMENTS

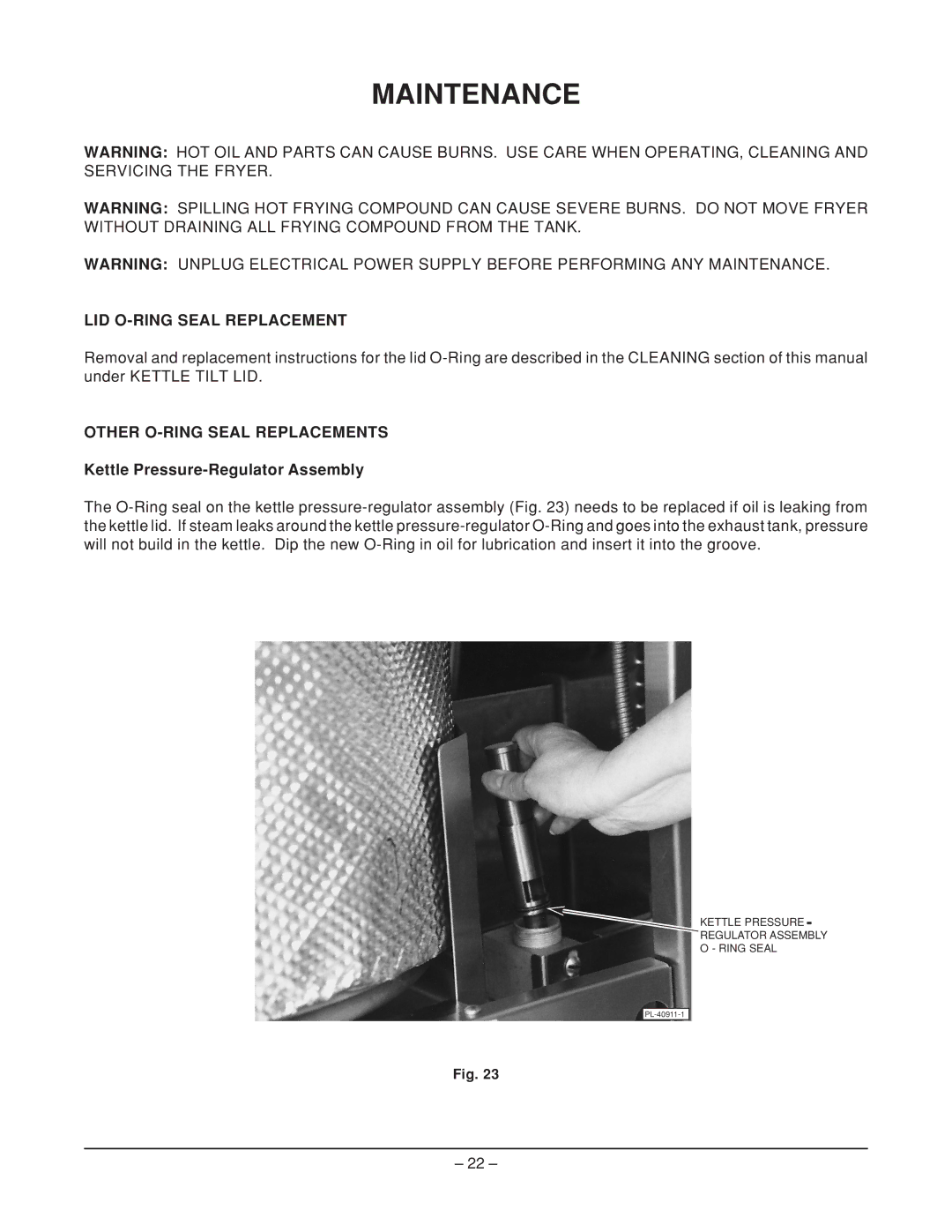

Kettle Pressure-Regulator Assembly

The

KETTLE PRESSURE -

REGULATOR ASSEMBLY

O - RING SEAL

Fig. 23

– 22 –