4-10. Flowmeter (Optional)

CAUTION

Wire feeding system is designed for maximum of 50 psi (345 kPa) gas pressure.

•Be sure that regulator/flowmeter has preset conditions of no more than 50 psi (345 kPa) gas pressure.

CFH

Ar CO2

60 ![]()

![]() 60

60

50 ![]()

![]() 50

50

40 ![]()

![]() 40

40

30 ![]()

![]() 30

30

20 ![]()

![]() 20

20

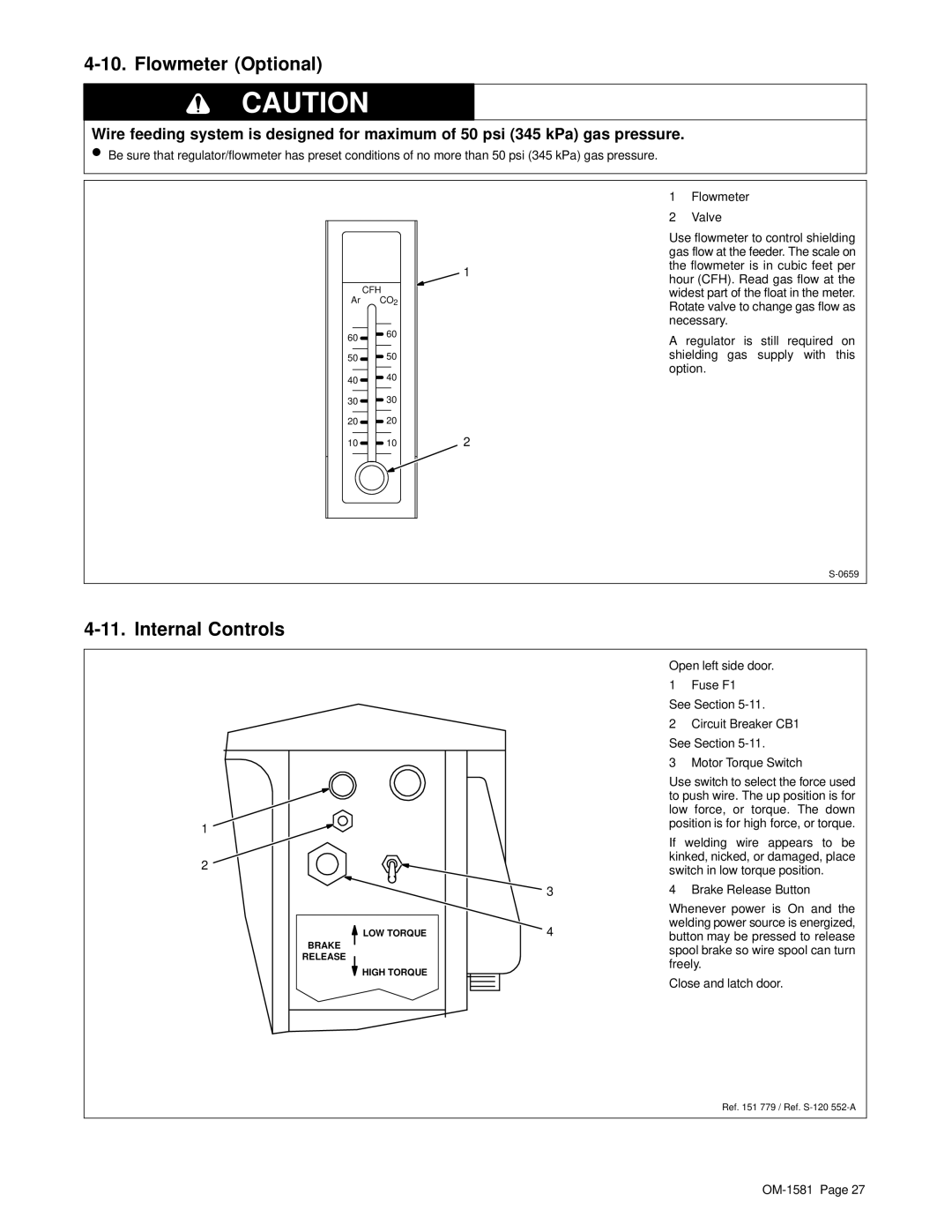

1Flowmeter

2Valve

Use flowmeter to control shielding gas flow at the feeder. The scale on the flowmeter is in cubic feet per hour (CFH). Read gas flow at the widest part of the float in the meter. Rotate valve to change gas flow as necessary.

A regulator is still required on shielding gas supply with this option.

10 ![]()

![]() 10

10

4-11. Internal Controls

1

2

BRAKE

RELEASE

![]() LOW TORQUE

LOW TORQUE

![]() HIGH TORQUE

HIGH TORQUE

3

4

Open left side door.

1 Fuse F1

See Section

2Circuit Breaker CB1 See Section

3Motor Torque Switch

Use switch to select the force used to push wire. The up position is for low force, or torque. The down position is for high force, or torque.

If welding wire appears to be kinked, nicked, or damaged, place switch in low torque position.

4 Brake Release Button

Whenever power is On and the welding power source is energized, button may be pressed to release spool brake so wire spool can turn freely.

Close and latch door.

Ref. 151 779 / Ref.