SECTION 4 – OPERATION

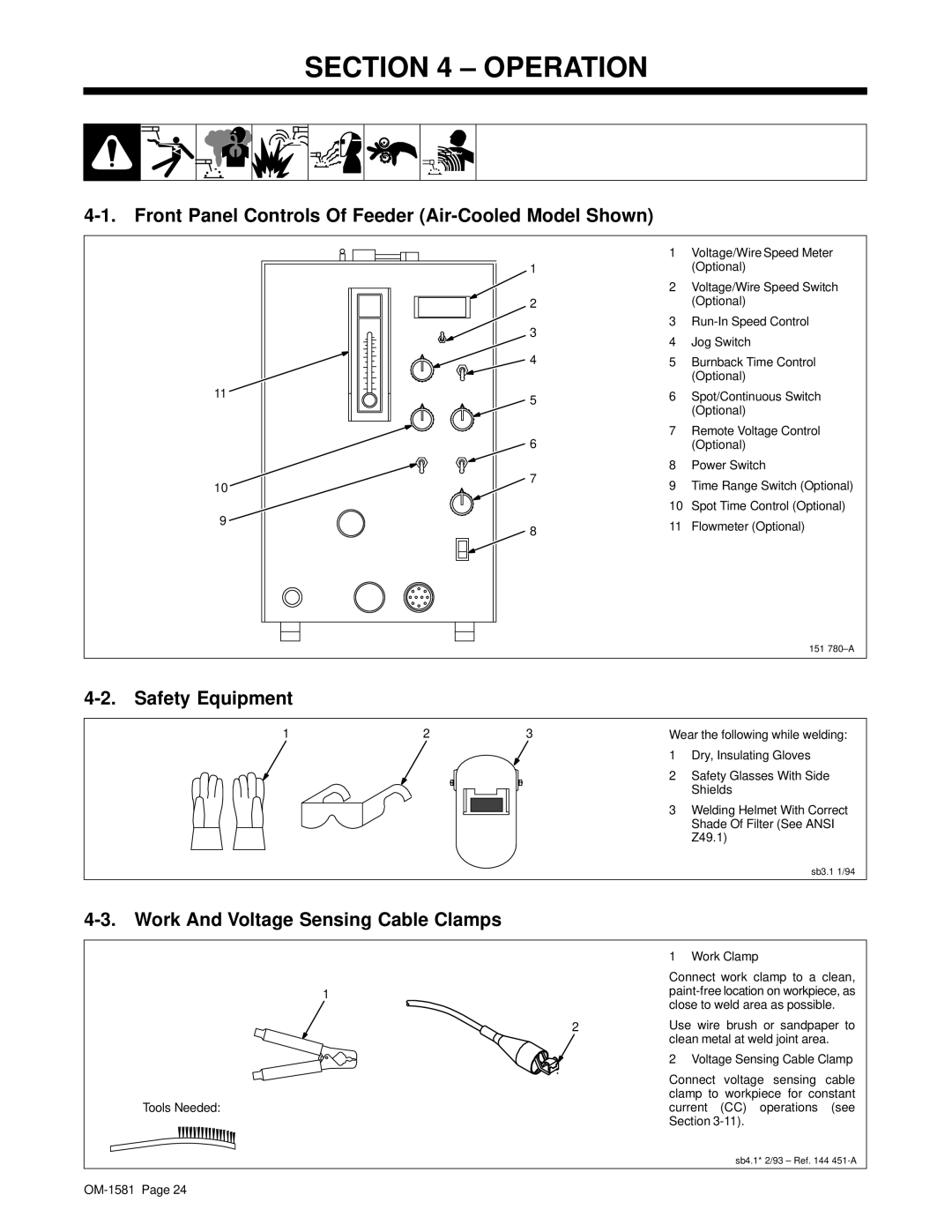

4-1. Front Panel Controls Of Feeder (Air-Cooled Model Shown)

|

| 1 | Voltage/Wire Speed Meter | |

| 1 |

| (Optional) | |

|

| 2 | Voltage/Wire Speed Switch | |

| 2 |

| (Optional) | |

| 3 | 3 | ||

| 4 | Jog Switch | ||

|

| |||

| 4 | 5 | Burnback Time Control | |

|

|

| (Optional) | |

11 | 5 | 6 | Spot/Continuous Switch | |

|

| (Optional) | ||

|

|

| ||

| 6 | 7 | Remote Voltage Control | |

|

| (Optional) | ||

| 7 | 8 | Power Switch | |

10 | 9 | Time Range Switch (Optional) | ||

| ||||

|

| 10 | Spot Time Control (Optional) | |

9 | 8 | 11 | Flowmeter (Optional) | |

| ||||

|

|

|

151

4-2. Safety Equipment

1 | 2 | 3 | Wear the following while welding: |

1 Dry, Insulating Gloves

2 Safety Glasses With Side

Shields

3 Welding Helmet With Correct

Shade Of Filter (See ANSI

Z49.1)

sb3.1 1/94

4-3. Work And Voltage Sensing Cable Clamps

1 Work Clamp

Connect work clamp to a clean,

1paint-free location on workpiece, as close to weld area as possible.

2 | Use wire brush or sandpaper to | ||

| clean metal at weld joint area. | ||

| 2 Voltage Sensing Cable Clamp | ||

| Connect | voltage sensing | cable |

| clamp to workpiece for constant | ||

Tools Needed: | current | (CC) operations | (see |

| Section |

| |

sb4.1* 2/93 – Ref. 144