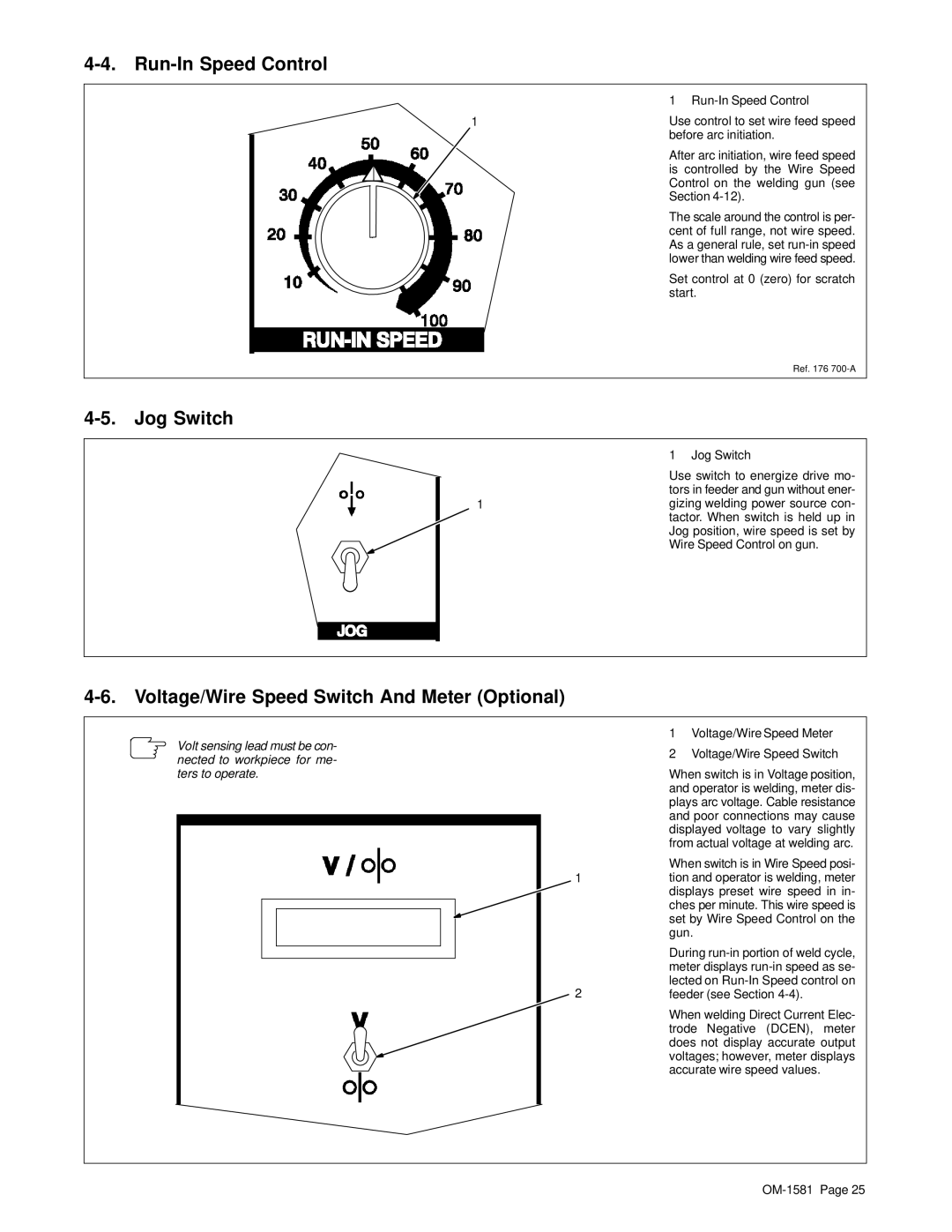

4-4. Run-In Speed Control

| 1 |

1 | Use control to set wire feed speed |

| before arc initiation. |

After arc initiation, wire feed speed is controlled by the Wire Speed Control on the welding gun (see Section

The scale around the control is per- cent of full range, not wire speed. As a general rule, set

Set control at 0 (zero) for scratch start.

Ref. 176

4-5. Jog Switch

1 Jog Switch

Use switch to energize drive mo- tors in feeder and gun without ener-

1gizing welding power source con- tactor. When switch is held up in Jog position, wire speed is set by Wire Speed Control on gun.

4-6. Voltage/Wire Speed Switch And Meter (Optional)

Volt sensing lead must be con- nected to workpiece for me- ters to operate.

1

2

1Voltage/Wire Speed Meter

2Voltage/Wire Speed Switch

When switch is in Voltage position, and operator is welding, meter dis- plays arc voltage. Cable resistance and poor connections may cause displayed voltage to vary slightly from actual voltage at welding arc.

When switch is in Wire Speed posi- tion and operator is welding, meter displays preset wire speed in in- ches per minute. This wire speed is set by Wire Speed Control on the gun.

During

When welding Direct Current Elec- trode Negative (DCEN), meter does not display accurate output voltages; however, meter displays accurate wire speed values.