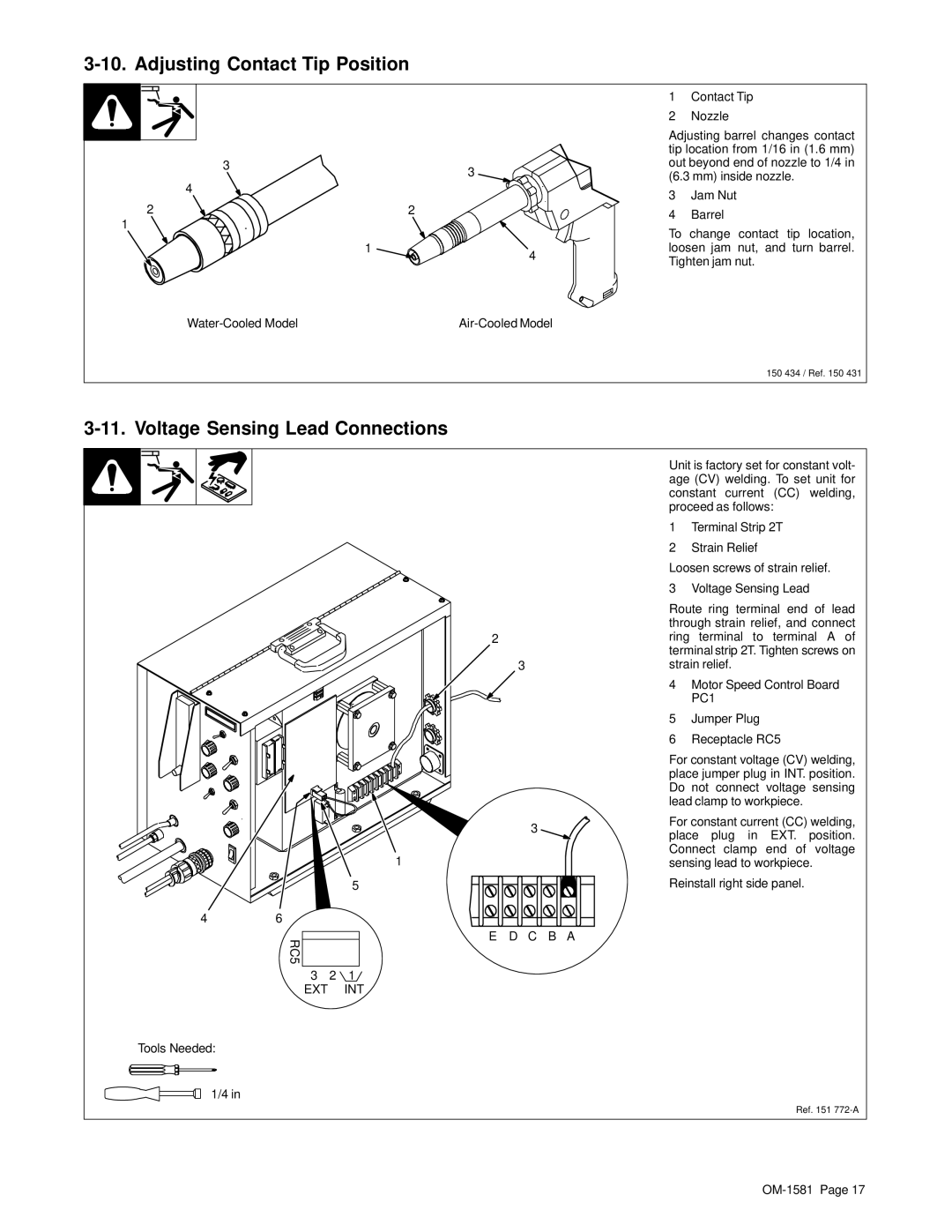

3-10. Adjusting Contact Tip Position

1Contact Tip

2Nozzle

3

4

3

Adjusting barrel changes contact tip location from 1/16 in (1.6 mm) out beyond end of nozzle to 1/4 in (6.3 mm) inside nozzle.

3 Jam Nut |

2 | 2 |

1

1

4

3-11. Voltage Sensing Lead Connections

2

3

|

|

| 3 |

|

|

| 1 |

|

|

| 5 |

4 | 6 |

|

|

| RC5 |

| E D C B A |

|

|

| |

| 3 | 2 | 1 |

| EXT |

| INT |

Tools Needed:

1/4 in

4 Barrel |

To change contact tip location, loosen jam nut, and turn barrel. Tighten jam nut.

150 434 / Ref. 150 431

Unit is factory set for constant volt- age (CV) welding. To set unit for constant current (CC) welding, proceed as follows:

1Terminal Strip 2T

2Strain Relief

Loosen screws of strain relief.

3 Voltage Sensing Lead

Route ring terminal end of lead through strain relief, and connect ring terminal to terminal A of terminal strip 2T. Tighten screws on strain relief.

4Motor Speed Control Board PC1

5Jumper Plug

6Receptacle RC5

For constant voltage (CV) welding, place jumper plug in INT. position. Do not connect voltage sensing lead clamp to workpiece.

For constant current (CC) welding, place plug in EXT. position. Connect clamp end of voltage sensing lead to workpiece.

Reinstall right side panel.

Ref. 151