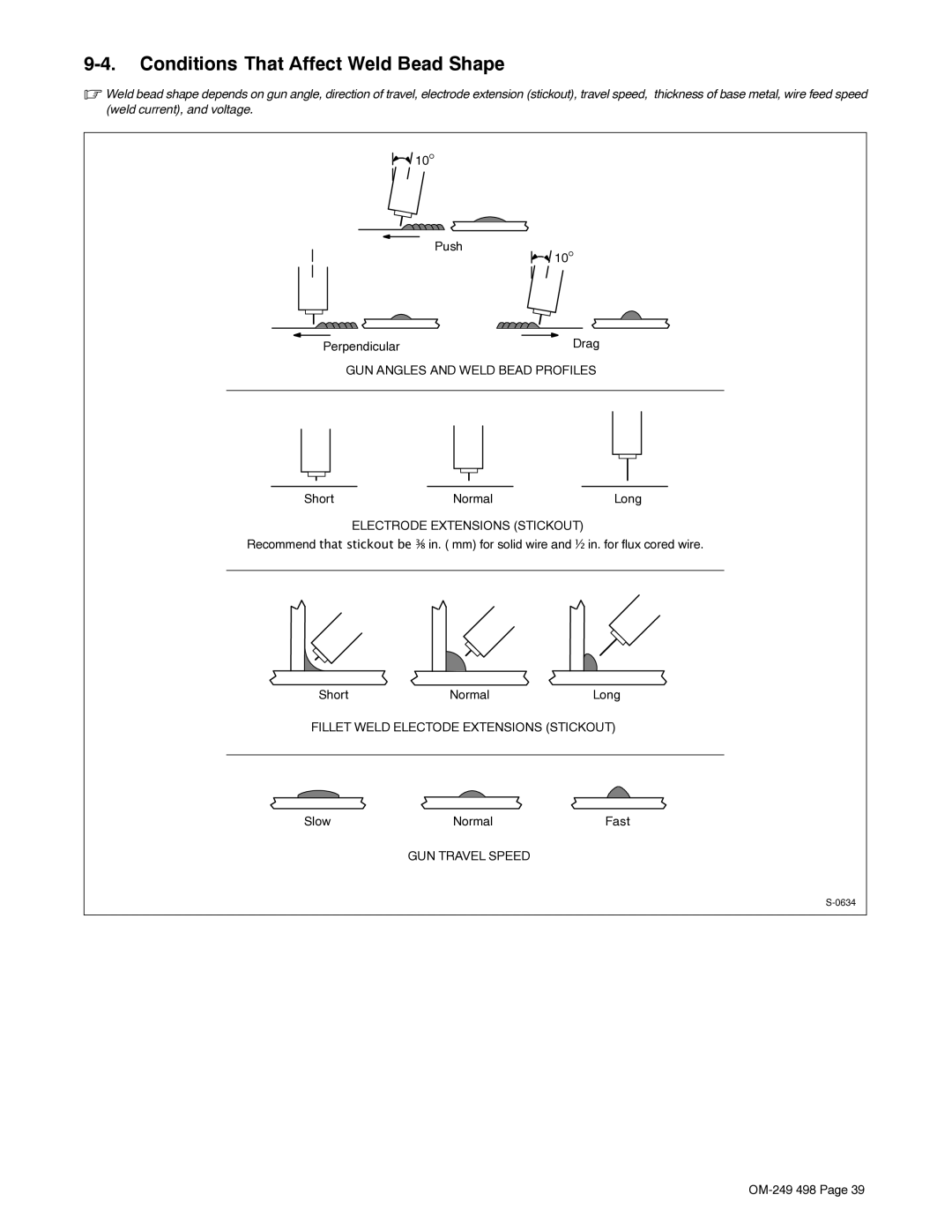

9-4. Conditions That Affect Weld Bead Shape

.Weld bead shape depends on gun angle, direction of travel, electrode extension (stickout), travel speed, thickness of base metal, wire feed speed (weld current), and voltage.

| 10° |

| Push |

| 10° |

Perpendicular | Drag |

GUN ANGLES AND WELD BEAD PROFILES

Short | Normal | Long |

ELECTRODE EXTENSIONS (STICKOUT)

Recommend that stickout be ⅜ in. ( mm) for solid wire and ½ in. for flux cored wire.

Short | Normal | Long |

FILLET WELD ELECTODE EXTENSIONS (STICKOUT)

Slow | Normal | Fast |

GUN TRAVEL SPEED