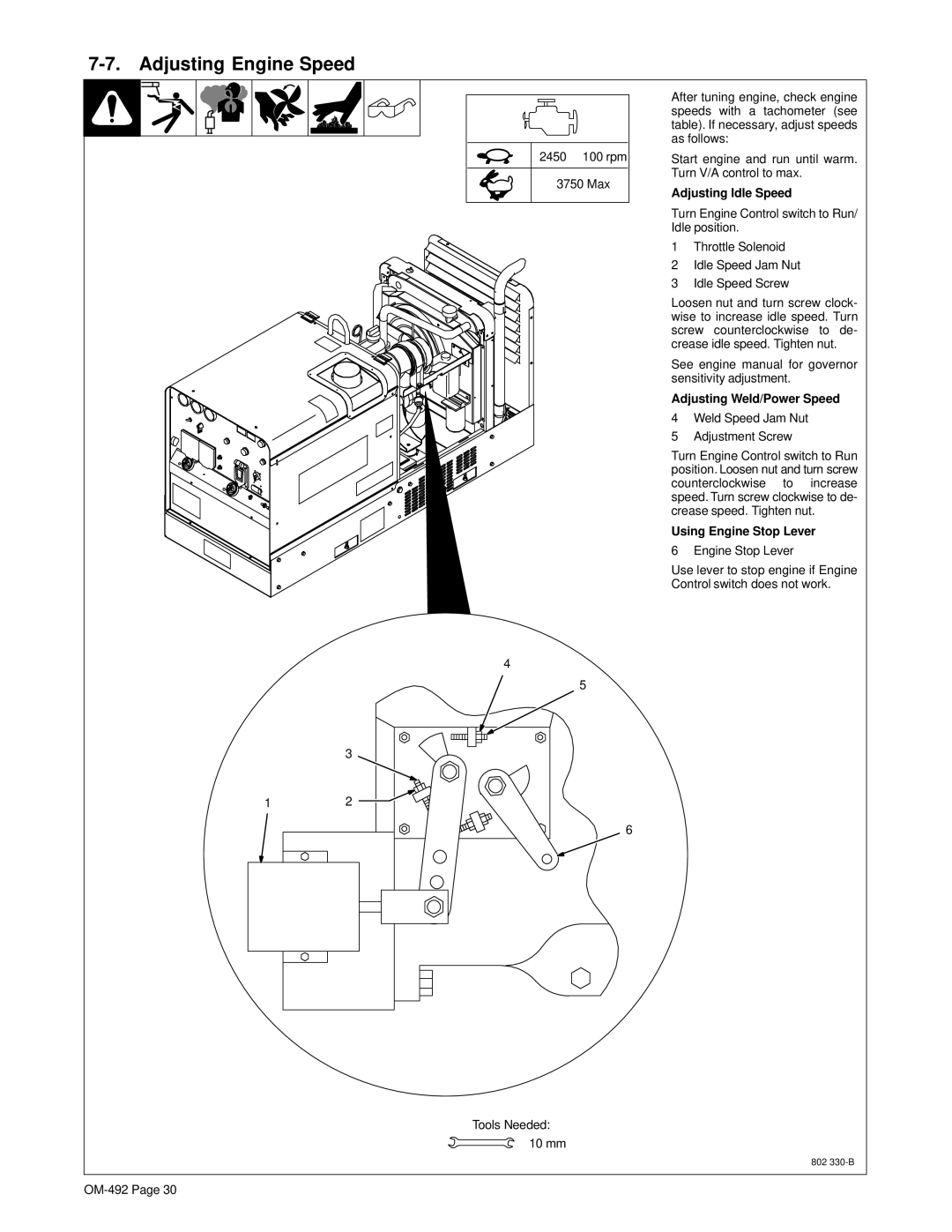

7-7. Adjusting Engine Speed

2450 ± 100 rpm

3750 Max

4

5

3

12

6

Tools Needed:

10 mm

After tuning engine, check engine speeds with a tachometer (see table). If necessary, adjust speeds as follows:

Start engine and run until warm. Turn V/A control to max.

Adjusting Idle Speed

Turn Engine Control switch to Run/ Idle position.

1Throttle Solenoid

2Idle Speed Jam Nut

3Idle Speed Screw

Loosen nut and turn screw clock- wise to increase idle speed. Turn screw counterclockwise to de- crease idle speed. Tighten nut.

See engine manual for governor sensitivity adjustment.

Adjusting Weld/Power Speed

4Weld Speed Jam Nut

5Adjustment Screw

Turn Engine Control switch to Run position. Loosen nut and turn screw counterclockwise to increase speed. Turn screw clockwise to de- crease speed. Tighten nut.

Using Engine Stop Lever

6 Engine Stop Lever

Use lever to stop engine if Engine Control switch does not work.

802