9-2. Run-In Procedure Using Load Bank

Y Stop engine.

Y Do not touch hot exhaust pipe, engine parts, or load bank/grid.

Y Keep exhaust and pipe away from flammables.

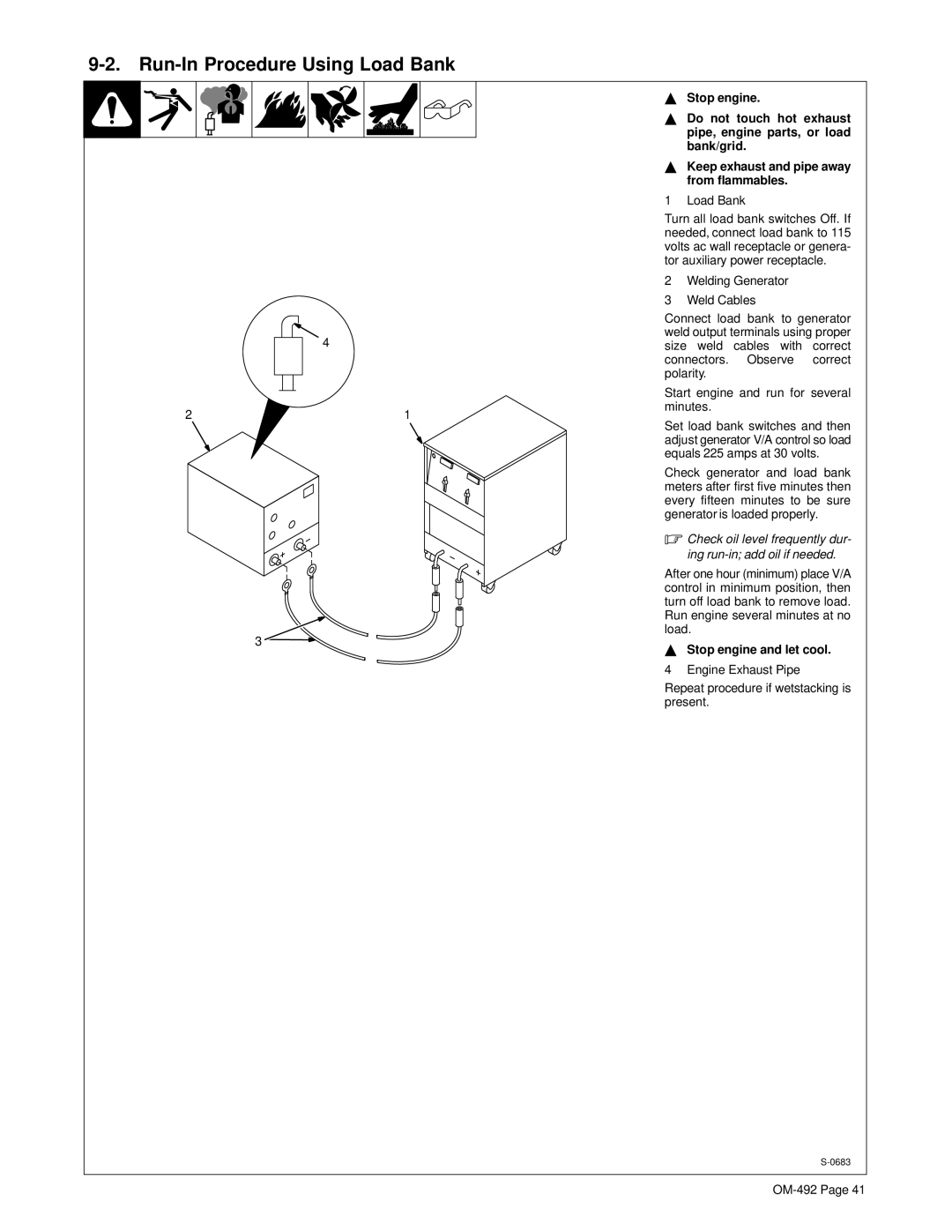

1 Load Bank

Turn all load bank switches Off. If needed, connect load bank to 115 volts ac wall receptacle or genera- tor auxiliary power receptacle.

2 Welding Generator

3 Weld Cables

Connect load bank to generator weld output terminals using proper

4size weld cables with correct connectors. Observe correct polarity.

| Start engine and run for several |

2 | minutes. |

1 |

3 ![]()

Set load bank switches and then adjust generator V/A control so load equals 225 amps at 30 volts.

Check generator and load bank meters after first five minutes then every fifteen minutes to be sure generator is loaded properly.

. Check oil level frequently dur- ing

After one hour (minimum) place V/A control in minimum position, then turn off load bank to remove load. Run engine several minutes at no load.

Y Stop engine and let cool.

4 Engine Exhaust Pipe

Repeat procedure if wetstacking is present.