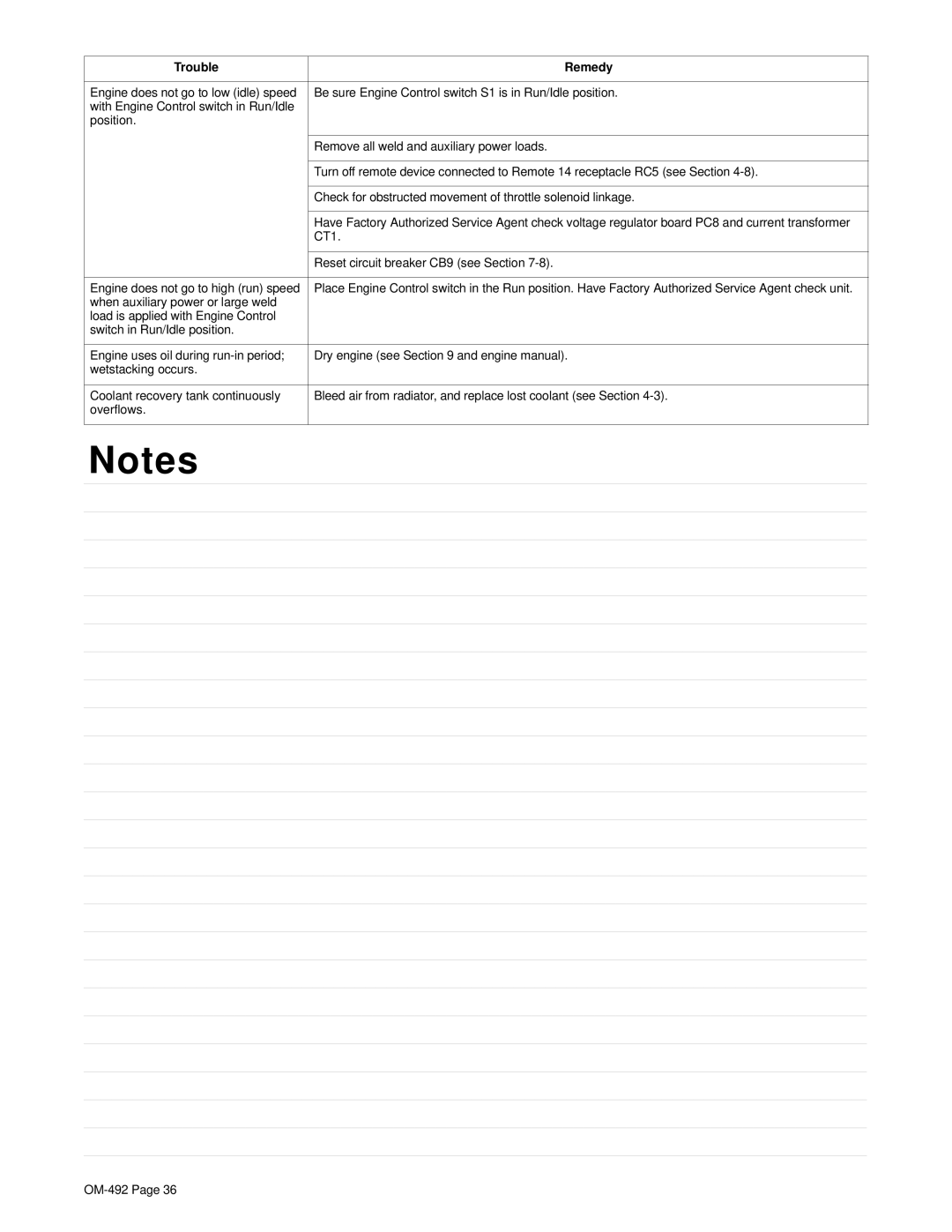

Trouble | Remedy |

|

|

Engine does not go to low (idle) speed | Be sure Engine Control switch S1 is in Run/Idle position. |

with Engine Control switch in Run/Idle |

|

position. |

|

|

|

| Remove all weld and auxiliary power loads. |

|

|

| Turn off remote device connected to Remote 14 receptacle RC5 (see Section |

|

|

| Check for obstructed movement of throttle solenoid linkage. |

|

|

| Have Factory Authorized Service Agent check voltage regulator board PC8 and current transformer |

| CT1. |

|

|

| Reset circuit breaker CB9 (see Section |

|

|

Engine does not go to high (run) speed | Place Engine Control switch in the Run position. Have Factory Authorized Service Agent check unit. |

when auxiliary power or large weld |

|

load is applied with Engine Control |

|

switch in Run/Idle position. |

|

|

|

Engine uses oil during | Dry engine (see Section 9 and engine manual). |

wetstacking occurs. |

|

|

|

Coolant recovery tank continuously | Bleed air from radiator, and replace lost coolant (see Section |

overflows. |

|

|

|

Notes