|

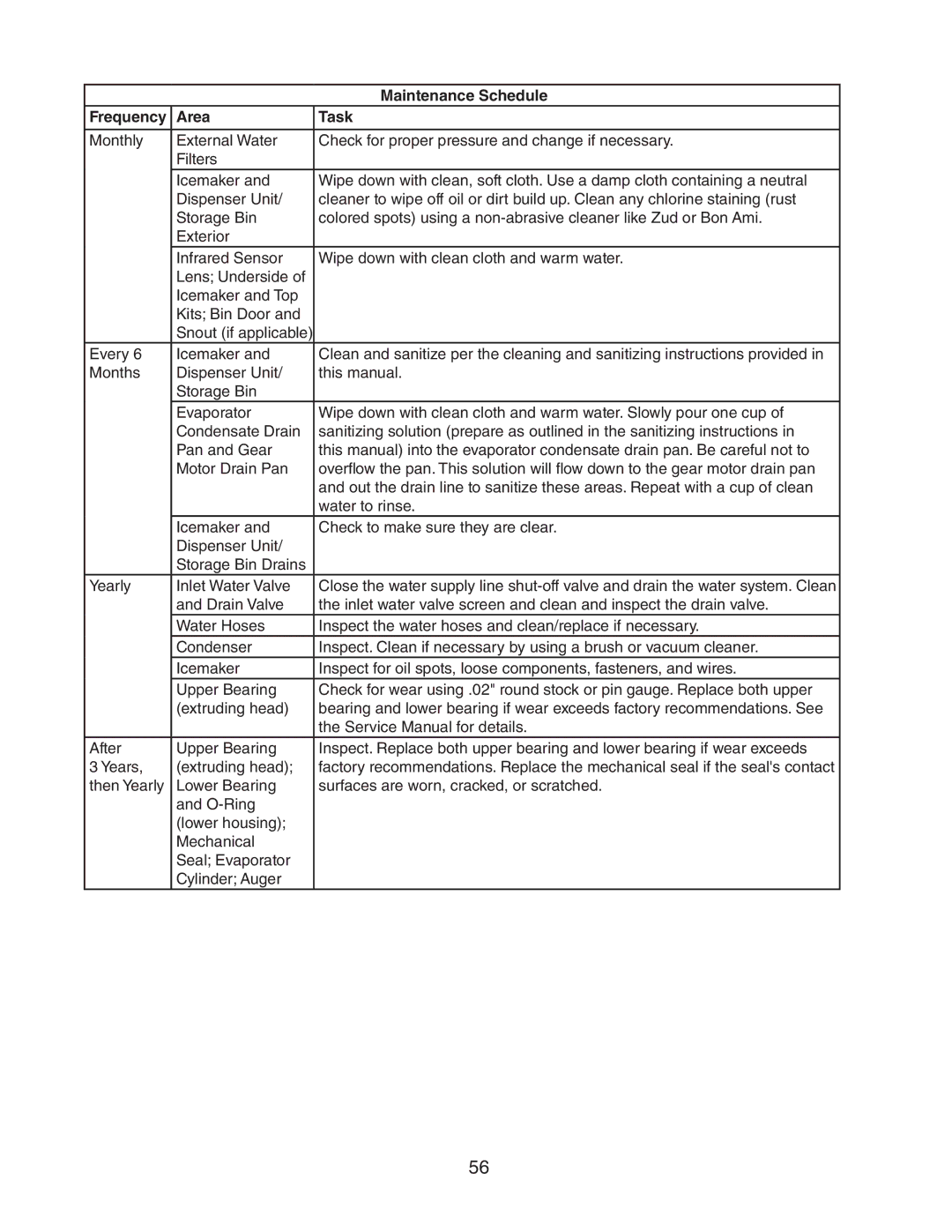

| Maintenance Schedule |

Frequency | Area | Task |

|

|

|

Monthly | External Water | Check for proper pressure and change if necessary. |

| Filters |

|

| Icemaker and | Wipe down with clean, soft cloth. Use a damp cloth containing a neutral |

| Dispenser Unit/ | cleaner to wipe off oil or dirt build up. Clean any chlorine staining (rust |

| Storage Bin | colored spots) using a |

| Exterior |

|

| Infrared Sensor | Wipe down with clean cloth and warm water. |

| Lens; Underside of |

|

| Icemaker and Top |

|

| Kits; Bin Door and |

|

| Snout (if applicable) |

|

Every 6 | Icemaker and | Clean and sanitize per the cleaning and sanitizing instructions provided in |

Months | Dispenser Unit/ | this manual. |

| Storage Bin |

|

| Evaporator | Wipe down with clean cloth and warm water. Slowly pour one cup of |

| Condensate Drain | sanitizing solution (prepare as outlined in the sanitizing instructions in |

| Pan and Gear | this manual) into the evaporator condensate drain pan. Be careful not to |

| Motor Drain Pan | overflow the pan. This solution will flow down to the gear motor drain pan |

|

| and out the drain line to sanitize these areas. Repeat with a cup of clean |

|

| water to rinse. |

| Icemaker and | Check to make sure they are clear. |

| Dispenser Unit/ |

|

| Storage Bin Drains |

|

Yearly | Inlet Water Valve | Close the water supply line shut‑off valve and drain the water system. Clean |

| and Drain Valve | the inlet water valve screen and clean and inspect the drain valve. |

| Water Hoses | Inspect the water hoses and clean/replace if necessary. |

| Condenser | Inspect. Clean if necessary by using a brush or vacuum cleaner. |

| Icemaker | Inspect for oil spots, loose components, fasteners, and wires. |

| Upper Bearing | Check for wear using .02" round stock or pin gauge. Replace both upper |

| (extruding head) | bearing and lower bearing if wear exceeds factory recommendations. See |

|

| the Service Manual for details. |

After | Upper Bearing | Inspect. Replace both upper bearing and lower bearing if wear exceeds |

3 Years, | (extruding head); | factory recommendations. Replace the mechanical seal if the seal's contact |

then Yearly | Lower Bearing | surfaces are worn, cracked, or scratched. |

| and |

|

| (lower housing); |

|

| Mechanical |

|

| Seal; Evaporator |

|

| Cylinder; Auger |

|

56