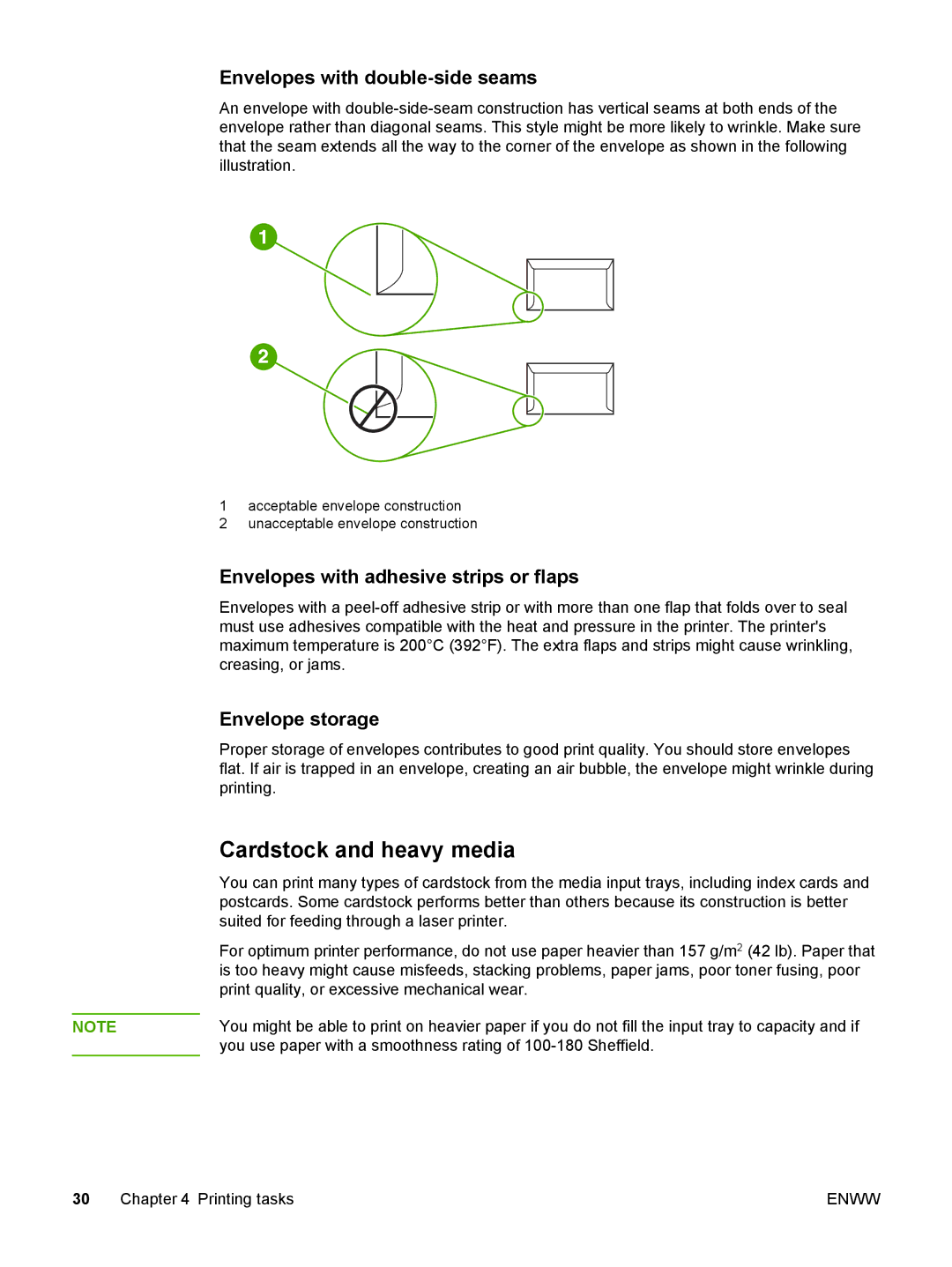

Envelopes with double-side seams

An envelope with

1 acceptable envelope construction

2 unacceptable envelope construction

Envelopes with adhesive strips or flaps

Envelopes with a

Envelope storage

Proper storage of envelopes contributes to good print quality. You should store envelopes flat. If air is trapped in an envelope, creating an air bubble, the envelope might wrinkle during printing.

| Cardstock and heavy media |

| You can print many types of cardstock from the media input trays, including index cards and |

| postcards. Some cardstock performs better than others because its construction is better |

| suited for feeding through a laser printer. |

| For optimum printer performance, do not use paper heavier than 157 g/m2 (42 lb). Paper that |

| is too heavy might cause misfeeds, stacking problems, paper jams, poor toner fusing, poor |

| print quality, or excessive mechanical wear. |

| You might be able to print on heavier paper if you do not fill the input tray to capacity and if |

NOTE | |

| you use paper with a smoothness rating of |

30 Chapter 4 Printing tasks | ENWW |