3-9 Water Reservoir

All portable chillers shipped during the fall, winter, or spring, or those units that are shipped from stock are flushed at the factory with a water/ethylene glycol solution to prevent piping components prone to retaining water from freezing. During startup and when additional solution is required, refer to the ethylene glycol and propylene glycol curves in Figure 6 on page 26. Add a

Glycol and/or water, with an inhibitor, should be used to protect the materials (copper, steel, stainless steel, and bronze) in the system from corrosion. If you intend to use straight water, we strongly advise a minimum leaving water temperature of 50ºF (10ºC) or contact the service department.

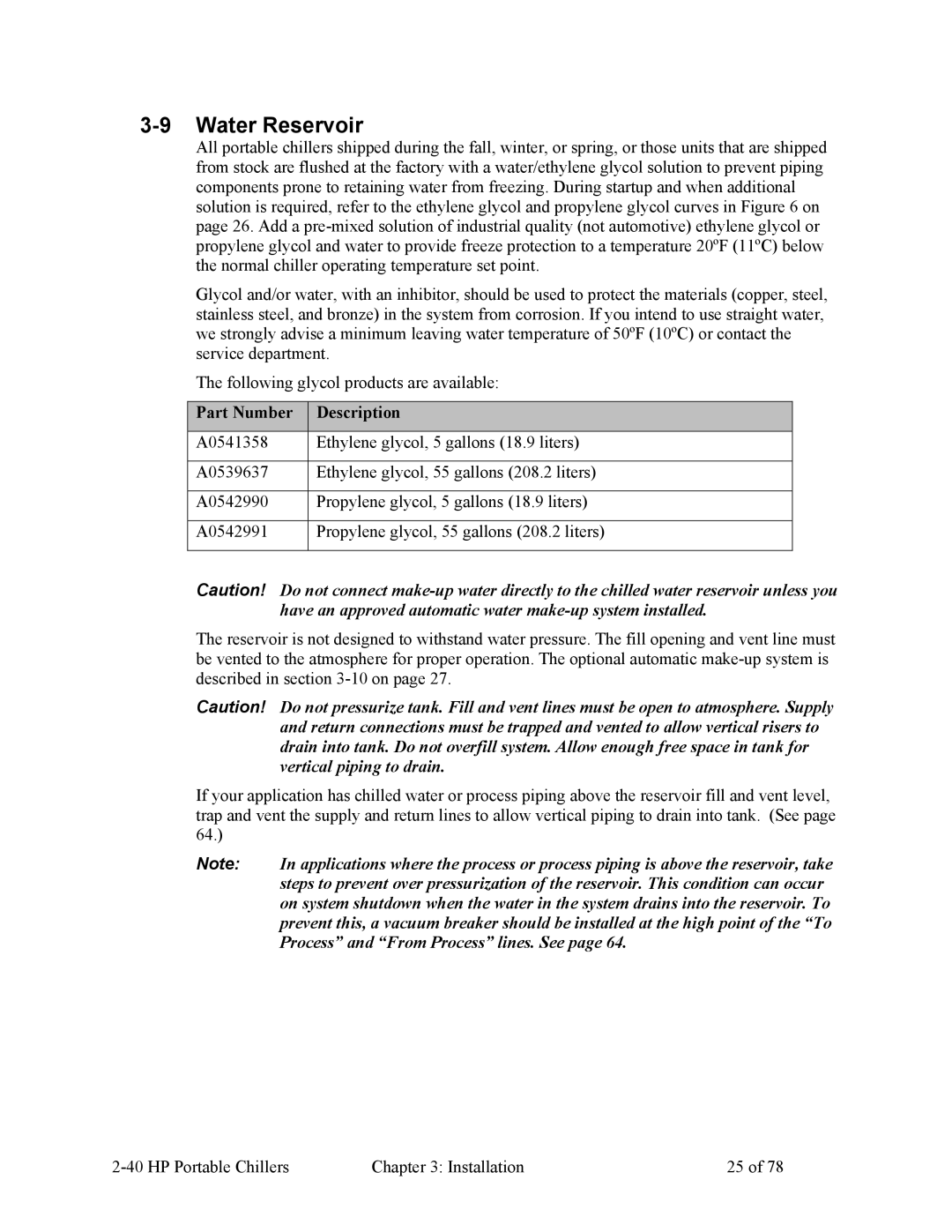

The following glycol products are available:

Part Number | Description |

|

|

A0541358 | Ethylene glycol, 5 gallons (18.9 liters) |

|

|

A0539637 | Ethylene glycol, 55 gallons (208.2 liters) |

|

|

A0542990 | Propylene glycol, 5 gallons (18.9 liters) |

|

|

A0542991 | Propylene glycol, 55 gallons (208.2 liters) |

|

|

Caution! Do not connect

The reservoir is not designed to withstand water pressure. The fill opening and vent line must be vented to the atmosphere for proper operation. The optional automatic

Caution! Do not pressurize tank. Fill and vent lines must be open to atmosphere. Supply and return connections must be trapped and vented to allow vertical risers to drain into tank. Do not overfill system. Allow enough free space in tank for vertical piping to drain.

If your application has chilled water or process piping above the reservoir fill and vent level, trap and vent the supply and return lines to allow vertical piping to drain into tank. (See page 64.)

Note: In applications where the process or process piping is above the reservoir, take steps to prevent over pressurization of the reservoir. This condition can occur on system shutdown when the water in the system drains into the reservoir. To prevent this, a vacuum breaker should be installed at the high point of the “To Process” and “From Process” lines. See page 64.

| Chapter 3: Installation | 25 of 78 |