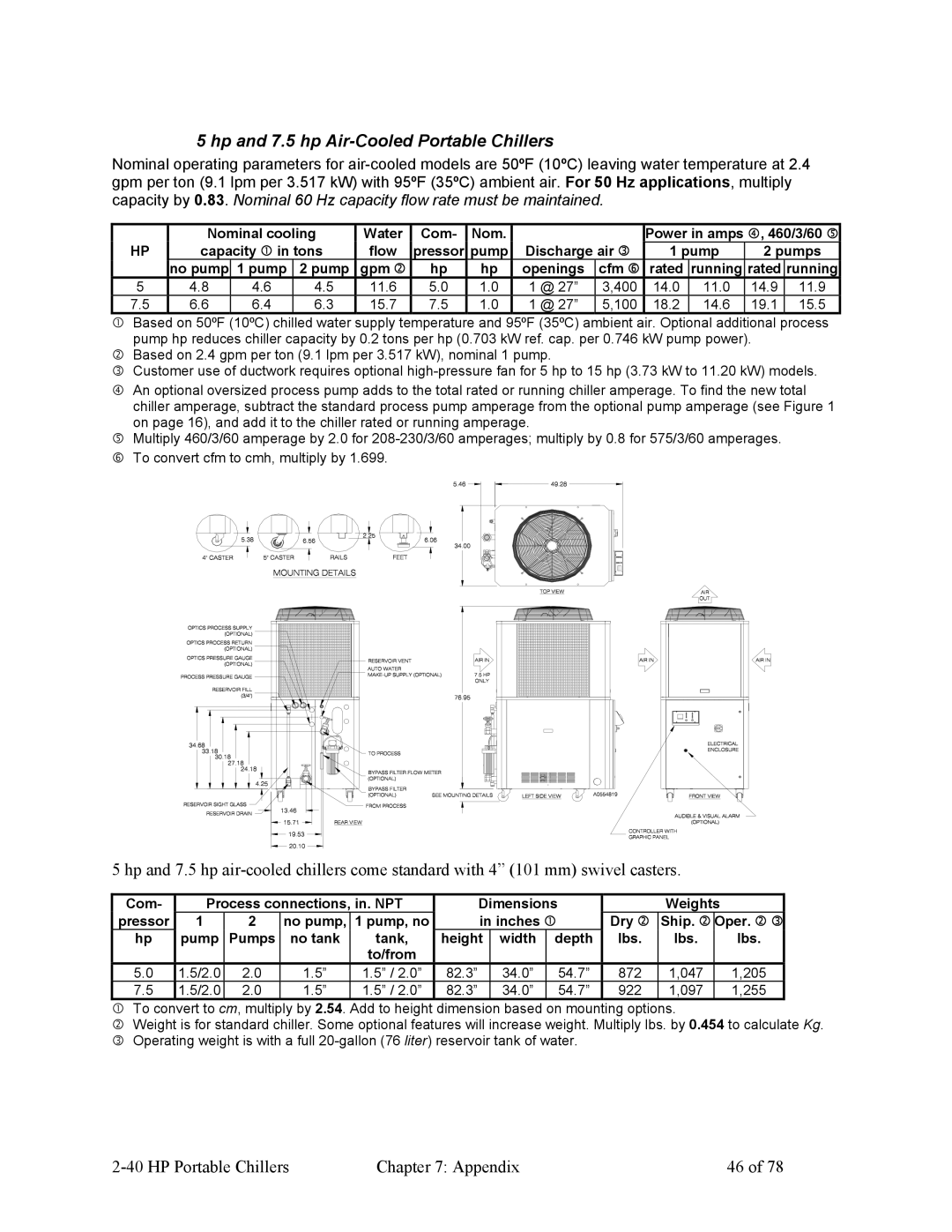

5 hp and 7.5 hp Air-Cooled Portable Chillers

Nominal operating parameters for

| Nominal cooling | Water | Com- | Nom. |

|

| Power in amps f, 460/3/60 g | |||||

HP | capacity c in tons | flow | pressor | pump | Discharge air e | 1 pump | 2 pumps | |||||

| no pump | 1 pump | 2 pump | gpm d | hp | hp | openings | cfm h | rated | running | rated | running |

5 | 4.8 | 4.6 | 4.5 | 11.6 | 5.0 | 1.0 | 1 @ 27” | 3,400 | 14.0 | 11.0 | 14.9 | 11.9 |

7.5 | 6.6 | 6.4 | 6.3 | 15.7 | 7.5 | 1.0 | 1 @ 27” | 5,100 | 18.2 | 14.6 | 19.1 | 15.5 |

cBased on 50ºF (10ºC) chilled water supply temperature and 95ºF (35ºC) ambient air. Optional additional process pump hp reduces chiller capacity by 0.2 tons per hp (0.703 kW ref. cap. per 0.746 kW pump power).

dBased on 2.4 gpm per ton (9.1 lpm per 3.517 kW), nominal 1 pump.

eCustomer use of ductwork requires optional

fAn optional oversized process pump adds to the total rated or running chiller amperage. To find the new total chiller amperage, subtract the standard process pump amperage from the optional pump amperage (see Figure 1

on page 16), and add it to the chiller rated or running amperage.

gMultiply 460/3/60 amperage by 2.0 for

5 hp and 7.5 hp

Com- | Process connections, in. NPT | Dimensions |

| Weights |

| ||||||

pressor | 1 | 2 | no pump, | 1 pump, no | in inches c | Dry d | Ship. d | Oper. d e | |||

hp | pump | Pumps | no tank | tank, | height | width | depth | lbs. | lbs. |

| lbs. |

|

|

|

| to/from |

|

|

|

|

|

|

|

5.0 | 1.5/2.0 | 2.0 | 1.5” | 1.5” / 2.0” | 82.3” | 34.0” | 54.7” | 872 | 1,047 |

| 1,205 |

7.5 | 1.5/2.0 | 2.0 | 1.5” | 1.5” / 2.0” | 82.3” | 34.0” | 54.7” | 922 | 1,097 |

| 1,255 |

cTo convert to cm, multiply by 2.54. Add to height dimension based on mounting options.

dWeight is for standard chiller. Some optional features will increase weight. Multiply lbs. by 0.454 to calculate Kg. e Operating weight is with a full

Chapter 7: Appendix | 46 of 78 |