Foamed PVC (Sintra® and other brand names)

Considerations

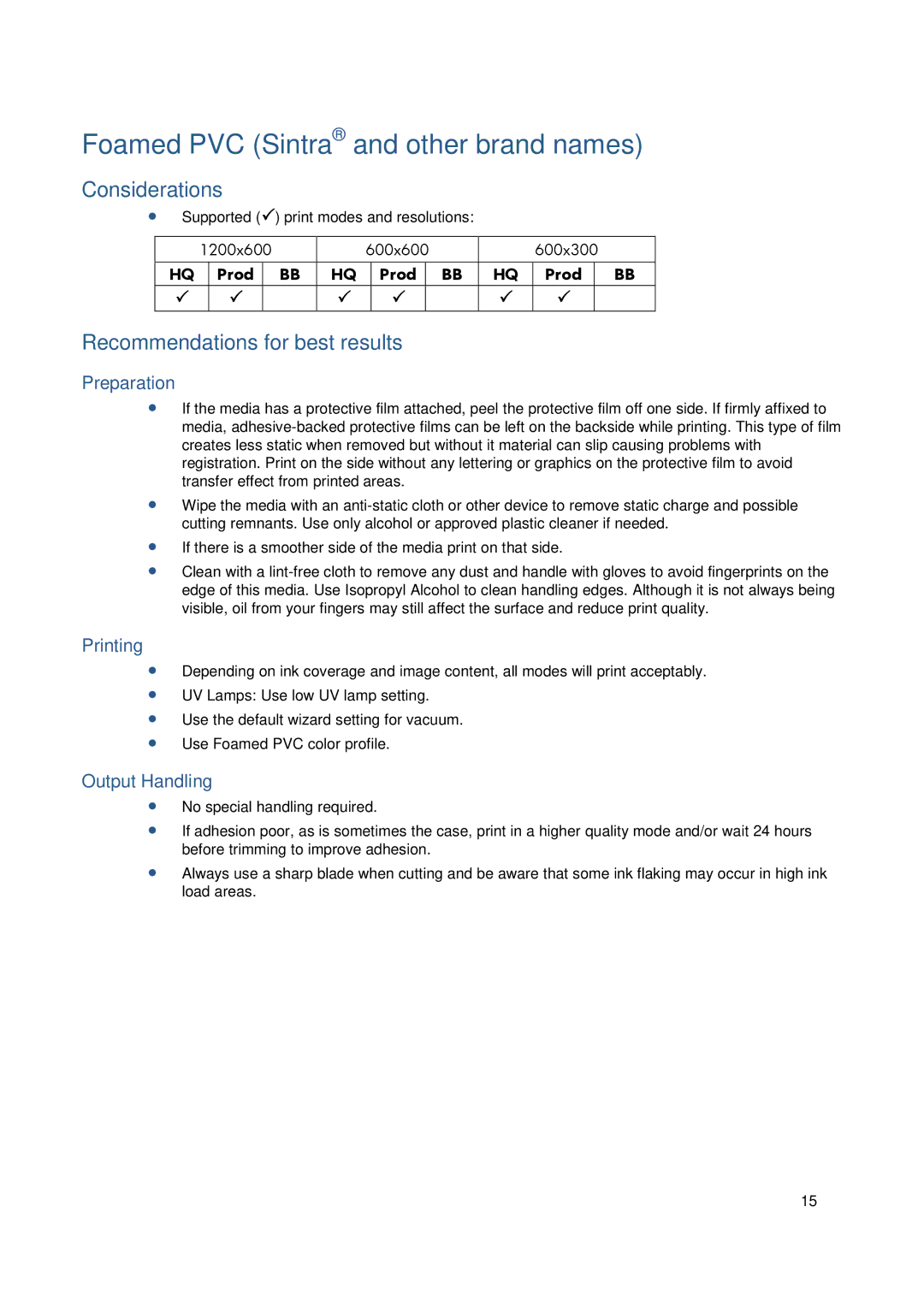

∙ Supported ( | ) print modes and resolutions: |

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

| 1200x600 |

| 600x600 |

| 600x300 |

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

| HQ | Prod |

| BB | HQ | Prod | BB | HQ | Prod |

| BB |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Recommendations for best results

Preparation

∙If the media has a protective film attached, peel the protective film off one side. If firmly affixed to media,

∙Wipe the media with an

∙If there is a smoother side of the media print on that side.

∙Clean with a

Printing

∙Depending on ink coverage and image content, all modes will print acceptably.

∙UV Lamps: Use low UV lamp setting.

∙Use the default wizard setting for vacuum.

∙Use Foamed PVC color profile.

Output Handling

∙No special handling required.

∙If adhesion poor, as is sometimes the case, print in a higher quality mode and/or wait 24 hours before trimming to improve adhesion.

∙Always use a sharp blade when cutting and be aware that some ink flaking may occur in high ink load areas.

15