Two-Sided Printing

General Notes

If

The success of

Loading Media for Two-Sided Printing

The printer automatically finds the media position from left to right (except in the special cases noted earlier), so positioning on the belt is not particularly difficult. Using the techniques for

Preparing Image for Two-Sided Printing

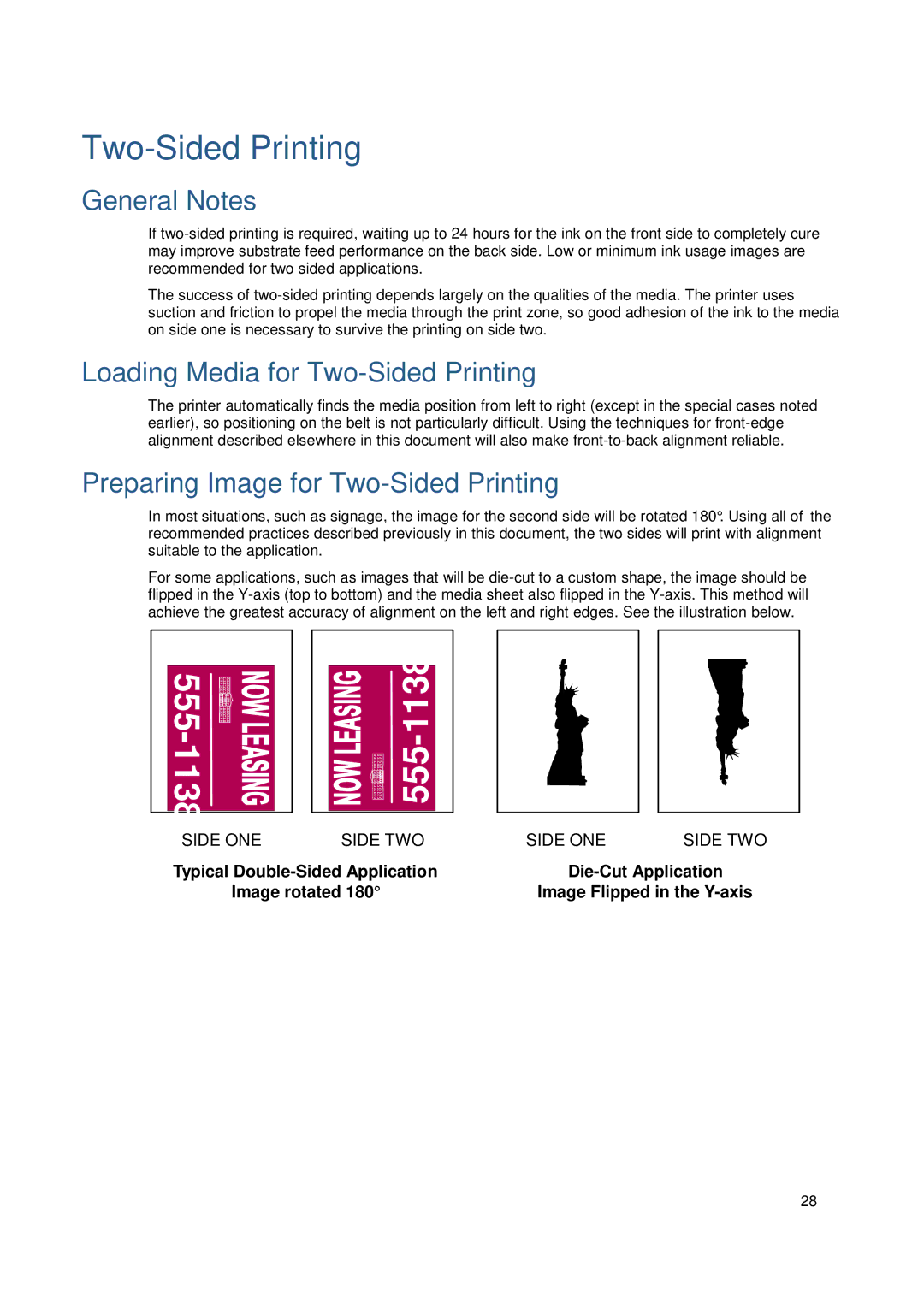

In most situations, such as signage, the image for the second side will be rotated 180°. Using all of the recommended practices described previously in this document, the two sides will print with alignment suitable to the application.

For some applications, such as images that will be

ERASMUSB. DRAGON M,ANAGEMENTINC. |

SIDE ONE

ERASMUSB. DRAGON | MANAGEMENT, INC. |

SIDE TWO

SIDE ONE | SIDE TWO |

Typical

Image rotated 180°

Image Flipped in the

28