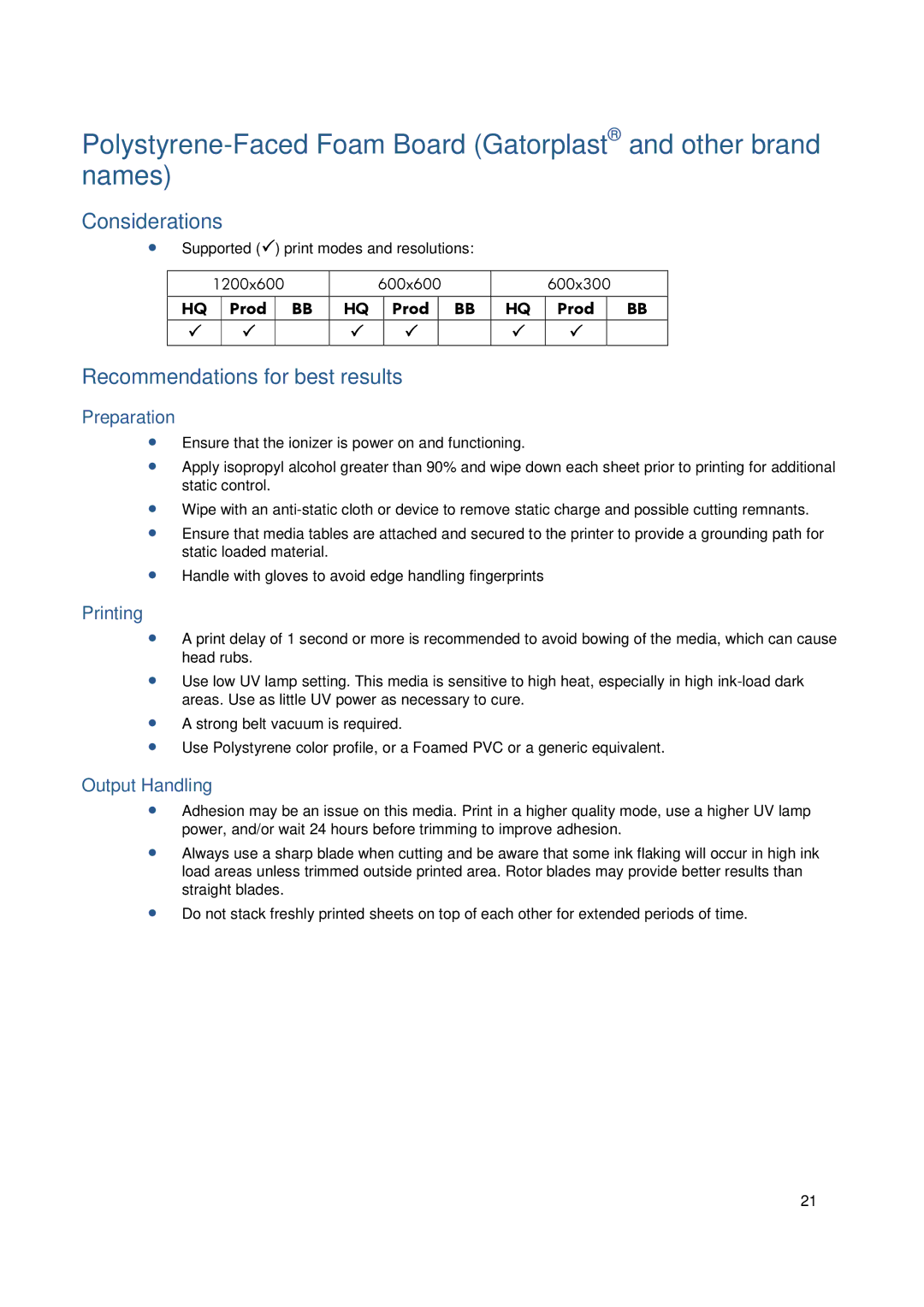

Considerations

∙ Supported ( | ) print modes and resolutions: |

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

| 1200x600 | 600x600 |

| 600x300 |

| |||||

|

|

|

|

|

|

|

|

|

|

|

| HQ | Prod | BB | HQ | Prod | BB | HQ | Prod |

| BB |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Recommendations for best results

Preparation

∙Ensure that the ionizer is power on and functioning.

∙Apply isopropyl alcohol greater than 90% and wipe down each sheet prior to printing for additional static control.

∙Wipe with an

∙Ensure that media tables are attached and secured to the printer to provide a grounding path for static loaded material.

∙Handle with gloves to avoid edge handling fingerprints

Printing

∙A print delay of 1 second or more is recommended to avoid bowing of the media, which can cause head rubs.

∙Use low UV lamp setting. This media is sensitive to high heat, especially in high

∙A strong belt vacuum is required.

∙Use Polystyrene color profile, or a Foamed PVC or a generic equivalent.

Output Handling

∙Adhesion may be an issue on this media. Print in a higher quality mode, use a higher UV lamp power, and/or wait 24 hours before trimming to improve adhesion.

∙Always use a sharp blade when cutting and be aware that some ink flaking will occur in high ink load areas unless trimmed outside printed area. Rotor blades may provide better results than straight blades.

∙Do not stack freshly printed sheets on top of each other for extended periods of time.

21