Plywood and Medium Density Overlay (MDO) Plywood Materials

Considerations

∙Due to the natural tendencies of Plywood and Medium Density Overlay Plywood (MDO) to warp and the overall surface smoothness of the product, it can be difficult to attain a consistent rate of media advance or produce repeatable results with this media. If deciding to print with this media, precautions should be taken to minimize the risk of printhead damage from warped media and to minimize the effects of poor media advances.

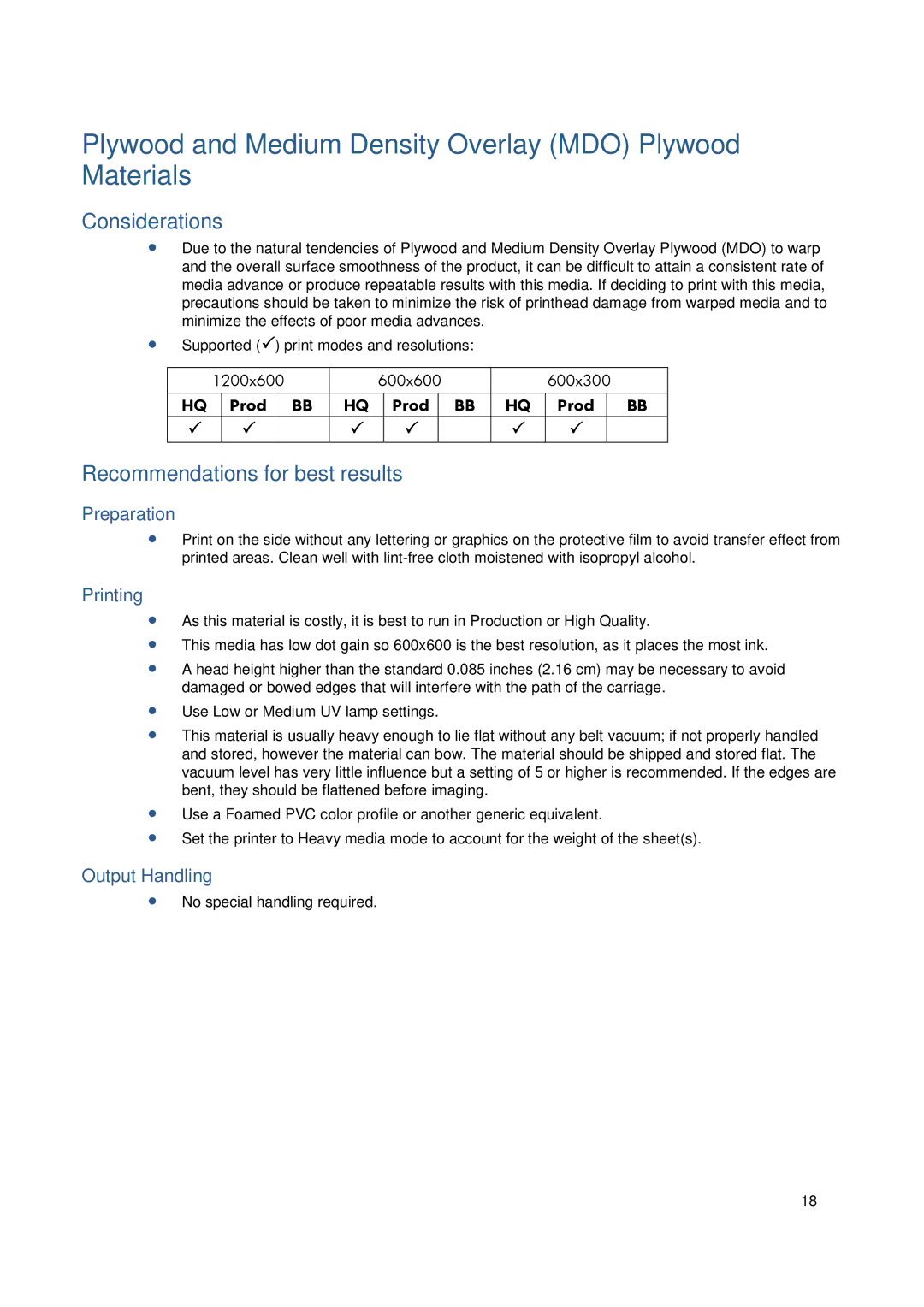

∙ Supported ( | ) print modes and resolutions: |

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

| 1200x600 | 600x600 |

| 600x300 |

| |||||

|

|

|

|

|

|

|

|

|

|

|

| HQ | Prod | BB | HQ | Prod | BB | HQ | Prod |

| BB |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Recommendations for best results

Preparation

∙Print on the side without any lettering or graphics on the protective film to avoid transfer effect from printed areas. Clean well with

Printing

∙As this material is costly, it is best to run in Production or High Quality.

∙This media has low dot gain so 600x600 is the best resolution, as it places the most ink.

∙A head height higher than the standard 0.085 inches (2.16 cm) may be necessary to avoid damaged or bowed edges that will interfere with the path of the carriage.

∙Use Low or Medium UV lamp settings.

∙This material is usually heavy enough to lie flat without any belt vacuum; if not properly handled and stored, however the material can bow. The material should be shipped and stored flat. The vacuum level has very little influence but a setting of 5 or higher is recommended. If the edges are bent, they should be flattened before imaging.

∙Use a Foamed PVC color profile or another generic equivalent.

∙Set the printer to Heavy media mode to account for the weight of the sheet(s).

Output Handling

∙No special handling required.

18