SECTION 6: PARTS SECTION

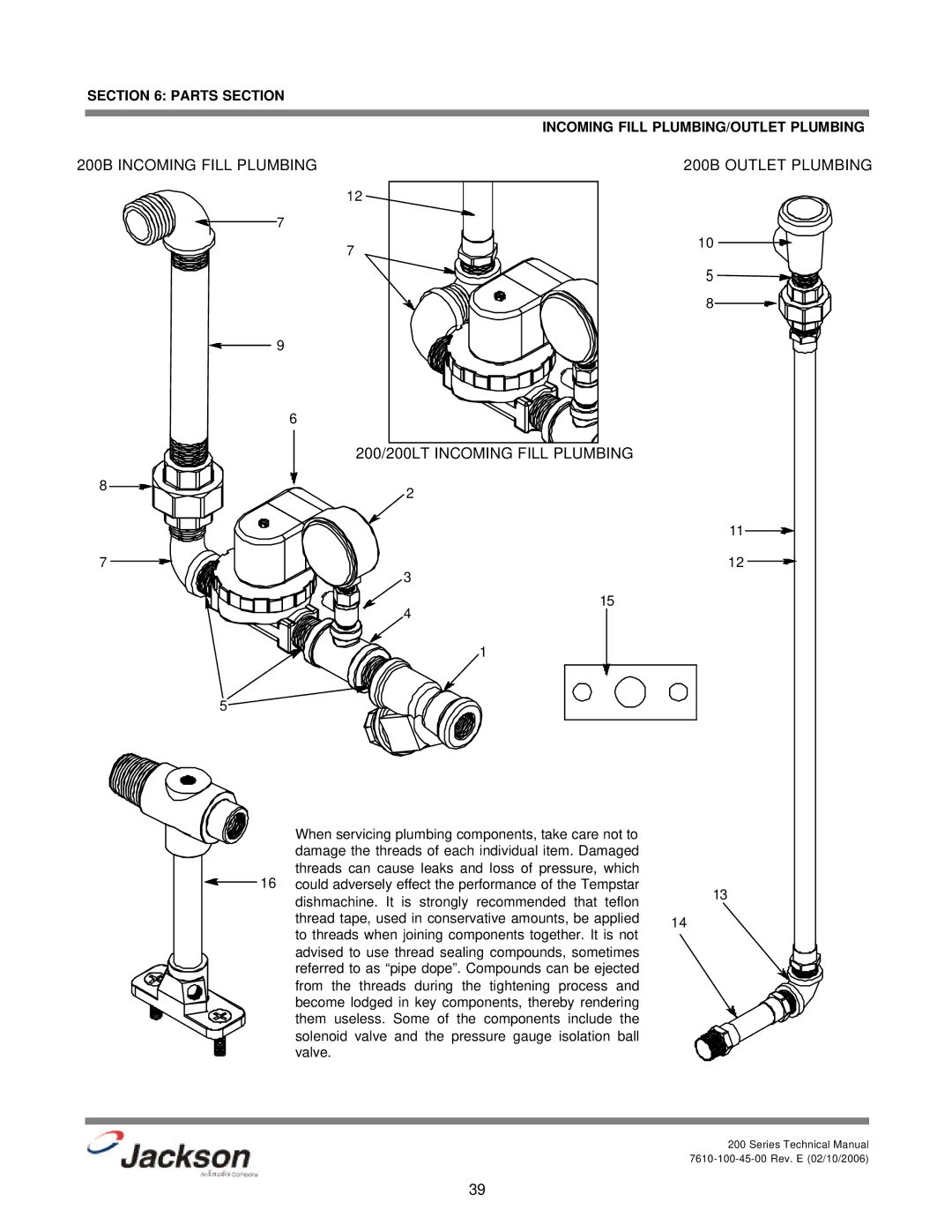

INCOMING FILL PLUMBING/OUTLET PLUMBING

200B INCOMING FILL PLUMBING | 200B OUTLET PLUMBING |

12 ![]()

7

7

9

6

10

5 ![]()

![]()

8

8

7

200/200LT INCOMING FILL PLUMBING

2

11

12

3

15

4

1

5![]()

When servicing plumbing components, take care not to |

| |

damage the threads of each individual item. Damaged |

| |

threads can cause leaks and loss of pressure, which |

| |

16 could adversely effect the performance of the Tempstar | 13 | |

dishmachine. It is strongly recommended that teflon | ||

| ||

thread tape, used in conservative amounts, be applied | 14 | |

to threads when joining components together. It is not | ||

| ||

advised to use thread sealing compounds, sometimes |

| |

referred to as “pipe dope”. Compounds can be ejected |

| |

from the threads during the tightening process and |

| |

become lodged in key components, thereby rendering |

| |

them useless. Some of the components include the |

| |

solenoid valve and the pressure gauge isolation ball |

| |

valve. |

|

200 Series Technical Manual

39