Operation Guide

Notice

Symbols

Notice on Software

Regarding Tradenames

1. License

2. Limited Warranty

IBM PROGRAM LICENSE AGREEMENT

3. Limitation of Remedies

9.New York, U.S.A. law governs this Agreement

Contents

Appendix C Host Computer Interface

Appendix E Specifications

CONTENTS

Appendix D Option Units

2. Guide to the Operation Guide

Introduction

1. For More Information

Item

Caution Labels

IMPORTANT! PLEASE READ FIRST

Other Precautions

Installation Precautions

QPower Supply/Grounding the Printer

QEnvironment

Precautions for Use

QCautions when Using the Printer

QCautions for Toner Handling

M G L K J I H

Chapter

Names of Parts

A B 1 C D E F 2 3 4

FCleaning brush

9Main switch

DCleaning knob

GPower cord

Inch specifications

Chapter 2 How to Load Paper

1. How to Load Paper

Metric specifications

Chapter 2 How to Load Paper

1.2Loading Paper into the MP Multi-Pur-pose Tray

1.3 Setting Envelopes

1. Understanding the Operator Panel

Chapter 3 Using the Operator Panel

Ready A4 PLAIN

DATA

Chapter 3 Using the Operator Panel

Indicator

Message

Paper Type

Paper Size

Display

Function

2. Using the Operator Panel

2.1 Menu Selection System

Continued

Continued

Continued on the next page

Print Quality >

Paper Handling >

Life Counters > Others >

3-10

2.2.1 Printing the Menu Map

2.2.2 Printing Status Page

STATUS PAGE

2.2.3 e-MPS

5Installed Options

8Error Log

3-11

e-MPS

>Report

>Private/Stored

>Agenda

>Print VMB Data

e-MPS

2.2.4 Changing the Interface Parameters

?Serial

>Baud Rate >Data Bits >Stop Bits >Parity None

>Protocol DTRpos.&XON >Barcode Mode Off

>Baud Rate

3-20

>>DHCP Off

Emulation

3-22

Emulation

2.2.6 Setting the Default Font

Font

2.2.7 Using Page Set Menus

Page Set

CS→CS98%

Page Set

>KIR Mode

2.2.8 Setting the Print Quality

Print Quality >

EcoPrint Mode

2.2.9 Operating an Option Hard Disk

3-31

DataH001

Hard Disk

>Read Data

>Write Data

Hard Disk

2.2.10 Operating a RAM Disk

3-34

? DataH001

3-35

2.2.11 Operating a Memory Card

Memory Card

?DataS001

Formatting

Memory Card

2.2.12 Paper Handling

6 7 8

Setting the MP Tray Size

3-40

Plain

Setting the MP Tray Type

>MP Tray Type

? Plain

>>Unit

Setting the Cassette Paper Type

>Cassette1 size

? mm

Binding Setups

Setting Duplex Printing

QBinding Setups

>Cassette 1 Type

Paper Handling >

>Override A4/LT

>Type Adjust > Custom

Customizing Paper Type

>Type Adjust

2.2.13 Other Modes

Others

Others

Others

>Buzzer

>>Print

>Service >

Q Printing the Service Status Page

>>Print Status Page ?

Symptom

Chapter 4 Troubleshooting

1. General Guide

See Indicators on page

Clean the charger wire

2. Print Quality Problems

Chapter 4 Troubleshooting

Replacement on page

Container Replacement on page

Check the EcoPrint setting

Setting the Print Quality on page

Check the charger unit installation

READY

3. Indicators and Messages

Condition

Close the printer front cover

a Paper Jam on page

Auto Continue Setting on page

on page

See Memory Card CF on page D-2

correct reading of the memory card

select Auto. See Page Protect Mode on page

Pager jam location

4. Correcting a Paper Jam

Paper jam message

Reference Page

4.1 Jam in Paper Cassette

4.2 Jam at the MP Tray

4-10

8 9 10

4.3 Jam in Left Cover

Close the front cover

4.5 Paper Jam at the Option Document Finisher

4.4 Jam in Left Cover

4-11

Specification

Chapter 5 Paper Selection

1. General Guidelines

Condition of the Paper

Chapter 5 Paper Selection

Basis Weight

Moisture Content

MP tray

Other Paper Properties

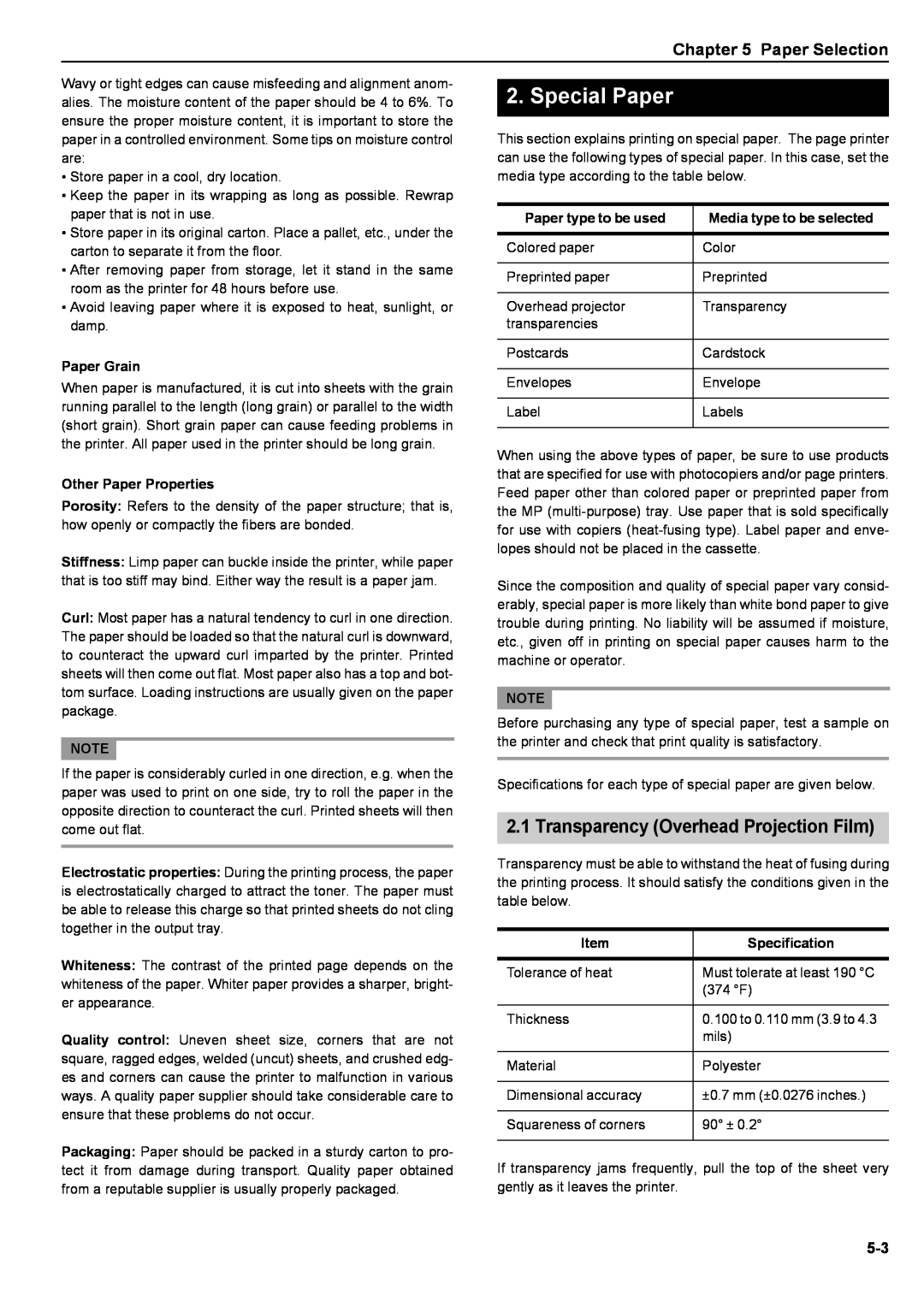

2. Special Paper

Paper Grain

Paper type to be used

Preprinted Paper

Envelopes

Colored Paper

Recycled Paper

Paper

3. Paper Type

Weight

Duplex path

Maintenance

1. Toner Container Replacement

When inserting, be sure that the gear side of the

Chapter 6 Maintenance

cover open to allow insertion of the waste toner

plastic bag and dispose of it

16 Remove the blue colored cleaning brush

Fonts

Appendix A

List of Fonts

Appendix A Fonts

3PCL Scalable and Bitmap Fonts

3KPDL Fonts

Appendix A Fonts

YES NO

Appendix B Expansion Memory

1. Removing the Main Circuit Board

2.1 Removing DIMM

2. Installing DIMMs

2.2 Testing the Expansion Memory

Appendix B Expansion Memory

Nibble high default

Appendix C Host Computer Interface

1. Parallel Interface

Parallel Connector Pin Assignment

Paper Empty PError Pin

2. Serial Interface

Data 0 1 to Data 7 8 Pins 2 to

Error* nFault Pin

Serial interface error

3. RS-232CProtocol

PRESCRIBE FRPO D0 command

Error

4.3 Setting the RS-232CParameters

4. RS-232CCable Connection

4.2 Connecting the RS-232CCable

4.1 Preparing an RS-232CCable

QDOS

Option Units

Appendix D

1. Available Options

PF-75Paper Feeder

Appendix D Option Units

PF-70Paper Feeder

Network Interface Card

2.2 DF-70/71/75Document Finishers

2. Installing Option Units

2.1 PF-70/75Paper Feeders

2.3 Network Interface

2.4 Hard Disk

2.5 Memory Card

Appendix E

Specifications

Specifications

Specifications

Appendix E Specifications

Cassette mode

Glossary

Glossary-1

dpi dots per inch

Printer driver

Glossary

Glossary-2

RAM disk

Index

Page

2-28, 1-Chome,Tamatsukuri, Chuo-ku

Kyocera Mita Corporation

Osaka 540-8585,Japan Phone: 06

Printer Driver Guide

Notice

Preface

Regarding Tradenames

Chapter 2 Setting the Defaults

Chapter 1 Installing the Printer Driver

Chapter 3 Printing Through Application Software

In the Select a device model window, click FS

Chapter 1 Installing the Printer Driver

9100DN or FS-9500DN

Chapter 1 Installing the Printer Driver

Browse Start > Settings > Printers

Chapter 2 Setting the Defaults

2.1 Adding Option Devices Setup

3 Click the Device Settings tab

Click the Device Settings tab

Chapter 2 Setting the Defaults

Check Large Capacity Feeder in the Device Options

Check Finisher in the Device Options list box

Chapter

2.1.4 Installing the Document Finisher DF-75

Setting the Defaults

the Device Options list

4 Check Hard Disk in the Device Options list box

4 Check RAM Disk in the Device Options list box

Click the Device Settings tab

Chapter 2 Setting the Defaults

Browse Start Settings Printers

Right click on the Kyocera Mita FS-9100DNKX or

Click the Device Settings tab

Chapter 2 Setting the Defaults

Browse Start > Settings > Printers

Right click on the Kyocera Mita FS-9100DNKX or

Chapter 2 Setting the Defaults

Guide

3.1 Setting the Paper Size

Chapter 3 Printing Through Application Software

FS-9100DNKX or Kyocera Mita FS-9500DNKX

Chapter 3 Printing Through Application Software

tom Size Settings on page

Select Same as Page Size in the Print Size drop

ters

3.1.1 Custom Size Settings

the Customized Paper Sizes list

Page Insert

3.1.2 Advanced Media Settings

leaving Cover Mode

Transparency Interleaving

the Flip on Long Edge or Flip on Short Edge radio

3.2 Setting the Duplex Printing

Click Print on Both Sides Duplex and then check

ing the Booklet Mode on page

1 2 3

3.3 Using the Booklet Mode

Select Finisher Face-down as Output to

Select Finisher Face-down or Finisher Face-up

3.4Using the Document Finisher DF-70/DF-71

Collate box

Finishing Options

document, All or Current page only in Page range

3.5 Using the Document Finisher

DF-75

Face-down or Finisher Face-up.To use the staple

Job Retention

3.6 e-MPS

Virtual MailBox

Code Job Temporary and Parmanent

Job Settings button

Quick Copy Printing

Proof and Hold Printing

Proof and Hold

Private Printing

Job Storage Stored Job Printing

Job Storage

3 Select the Device Settings tab

3Before Using VMB

1 Browse Start > Settings > Printers

Select PCL XL or PCL 5e in the Page Description

3Using VMB Printing

Virtual Mail Box VMB

Settings button

porary or Permanent radio button

Upper left

horizontal

vertical

Lower left

2-28, 1-Chome,Tamatsukuri, Chuo-ku

Kyocera Mita Corporation

Osaka 540-8585,Japan Phone: 06