|

| INSTALLATION |

| |||

OUTPUT CONNECTIONS |

| purchased separately. The accessories section of this | ||||

| WARNING |

| This unit does not include a TIG torch, but one may be | |||

|

| and TIG Torch Starter Packs that are recommended | ||||

|

|

|

| manual lists a number of Lincoln Electric TIG torches, | ||

| ELECTRIC SHOCK can kill. |

| for use with this machine; however, any similar TIG | |||

|

| torch can be used. To attach the | ||||

| • Insulate yourself from work and | Lincoln Torch, slide the rubber boot onto the torch | ||||

| ground. |

|

| cable (enlarge the boot opening if necessary), screw | ||

| • Turn the input line Switch on the | the fitting on the torch cable into the brass connector | ||||

| snugly and slide the boot back over the brass connec- | |||||

| Invertec V310T AC/DC “off” before | tor. |

|

| ||

| connecting or disconnecting output | TIG ADAPTER |

| STRAIN RELIEF BOOT | ||

| cables or other equipment. |

|

|

| ||

• Keep the electrode holder, TIG torch and cable |

|

|

| |||

insulation in good condition and in place. |

|

|

| |||

• Do not touch electrically live parts or electrode | RE AINING C M U ND |

| G R H P W R CABLE WITH GA S F NG | |||

with skin or wet clothing. |

|

| OUTPUT CONNECTION FOR STICK | |||

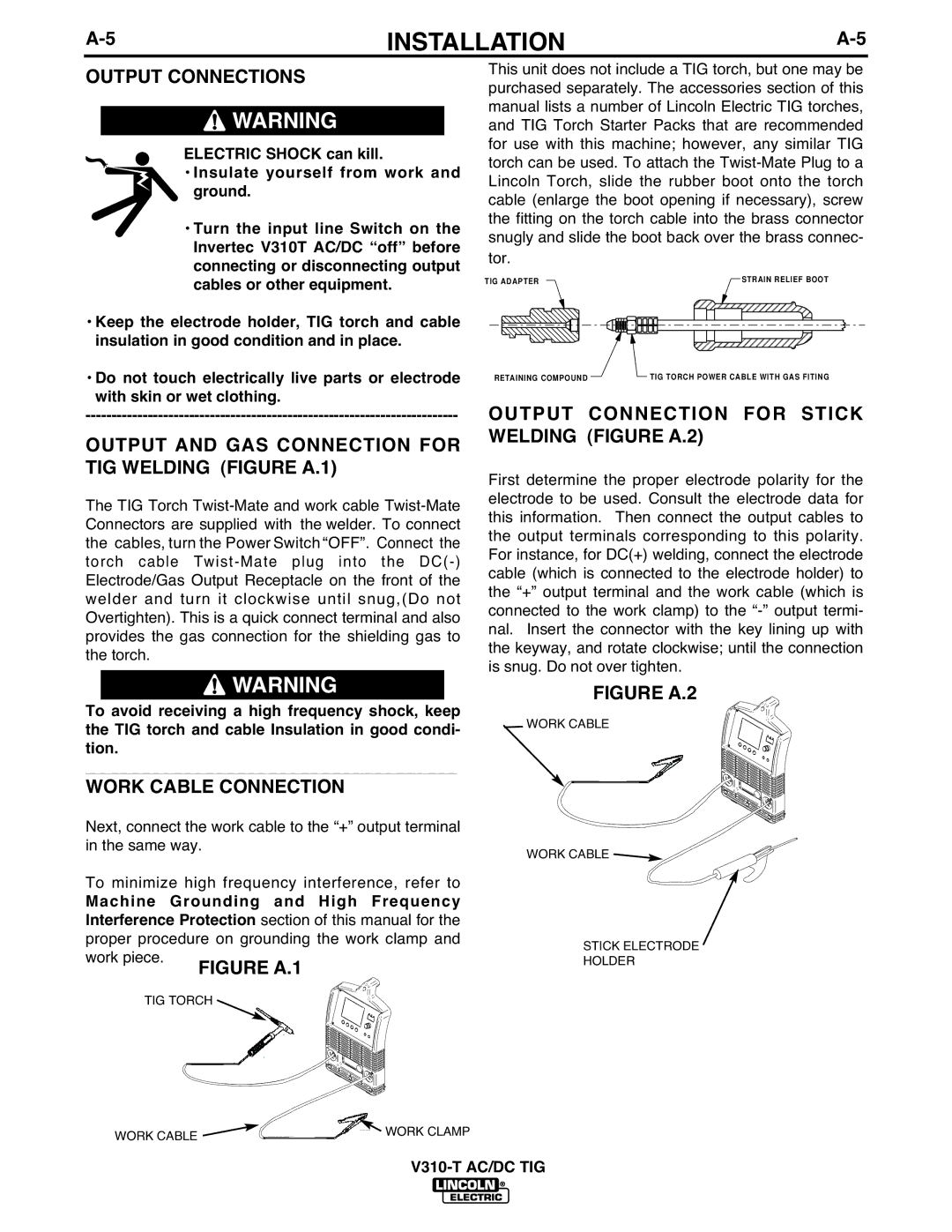

OUTPUT AND GAS CONNECTION FOR | WELDING (FIGURE A.2) | |||||

TIG WELDING (FIGURE A.1) |

| First determine the proper electrode polarity for the | ||||

The TIG Torch | electrode to be used. Consult the electrode data for | |||||

this information. | Then connect the output cables to | |||||

Connectors are supplied with | the welder. To connect | the output terminals corresponding to this polarity. | ||||

the cables, turn the Power Switch “OFF”. Connect the | For instance, for DC(+) welding, connect the electrode | |||||

torch cable | cable (which is connected to the electrode holder) to | |||||

Electrode/Gas Output Receptacle on the front of the | the “+” output terminal and the work cable (which is | |||||

welder and turn it clockwise until snug,(Do not | connected to the work clamp) to the | |||||

Overtighten). This is a quick connect terminal and also | nal. Insert the connector with the key lining up with | |||||

provides the gas connection for the shielding gas to | the keyway, and rotate clockwise; until the connection | |||||

the torch. | WARNING |

| is snug. Do not over tighten. | |||

|

|

| FIGURE A.2 | |||

To avoid receiving a high frequency shock, keep | WORK CABLE |

| ||||

the TIG torch and cable Insulation in good condi- |

| |||||

tion. |

|

|

|

|

|

|

___________________________________________ |

|

|

| |||

WORK CABLE CONNECTION |

|

|

|

| ||

Next, connect the work cable to the “+” output terminal | WORK CABLE |

| ||||

in the same way. |

|

|

| |||

To minimize high frequency interference, refer to |

|

|

| |||

Machine Grounding and High Frequency |

|

|

| |||

Interference Protection section of this manual for the | STICK ELECTRODE | |||||

proper procedure on grounding the work clamp and | ||||||

work piece. | FIGURE A.1 |

| HOLDER | |||

TIG TORCH |

|

|

|

|

| |

WORK CABLE |

| WORK CLAMP |

|

|

| |

|

|

|

|

| ||