|

|

|

| OPERATION |

|

|

|

| |||||||

| 3. The Mode Push Buttons and Indicators show the |

|

|

|

|

|

|

| |||||||

| current selection made by the corresponding weld |

|

|

|

|

|

|

| mode is only available when the | ||||||

|

|

|

|

|

|

|

| ||||||||

| push buttons |

|

|

|

| 2S |

| machine senses a remote amperage | |||||||

|

|

|

|

|

| ||||||||||

| of all parameters and their ranges. Below is a |

|

|

|

|

|

|

| control device is plugged in. It is used | ||||||

| description of the function of each push button and |

|

|

|

|

|

|

| when a foot or hand amptrol is | ||||||

| display: |

|

|

|

|

|

|

|

|

|

|

| plugged in. When this trigger mode is | ||

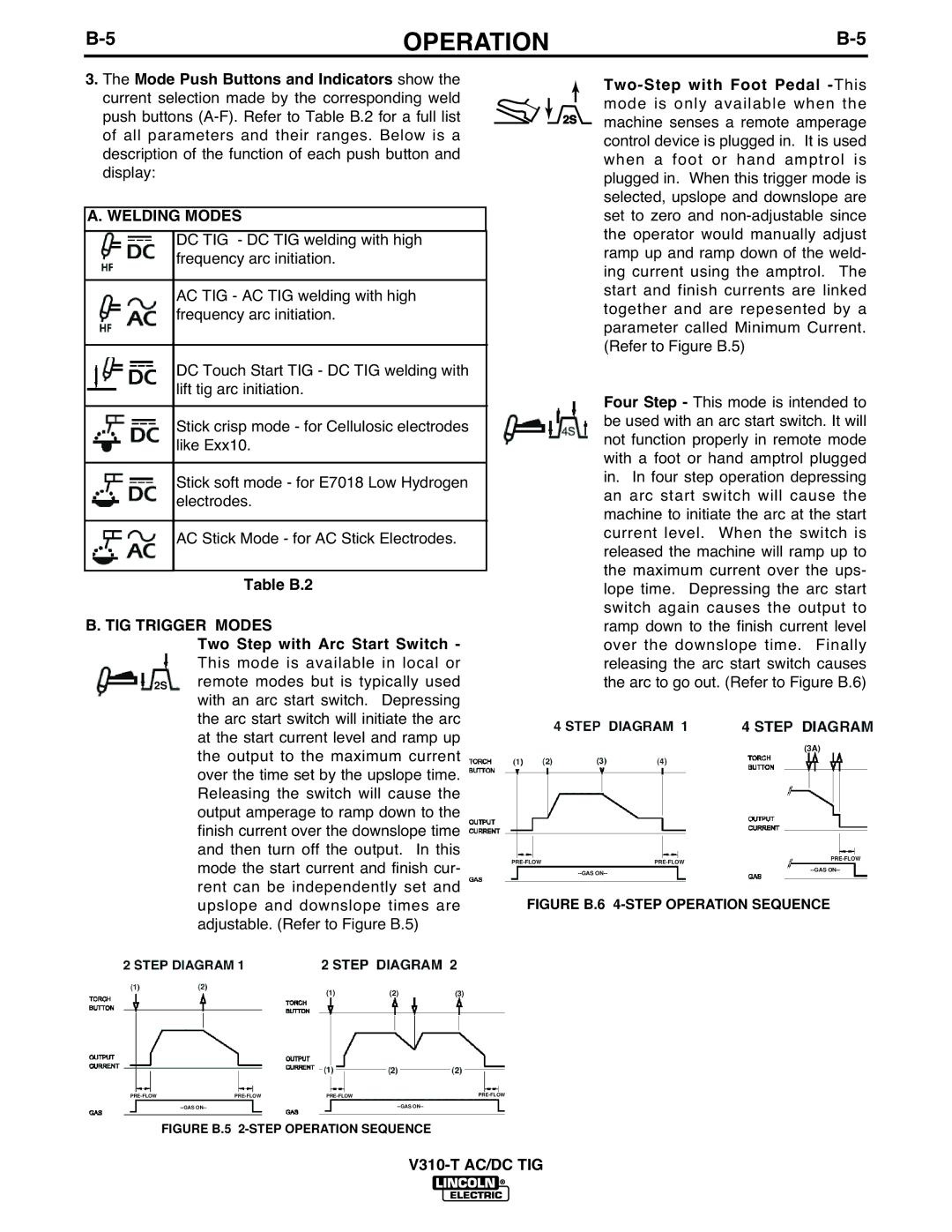

| A. WELDING MODES |

|

|

|

|

|

|

|

|

|

| selected, upslope and downslope are | |||

|

|

|

|

|

|

|

|

|

|

| set to zero and | ||||

|

|

|

|

|

|

|

| ||||||||

|

|

| DC TIG - DC TIG welding with high |

|

|

|

|

|

|

|

| the operator would manually adjust | |||

|

|

|

|

|

|

|

| ||||||||

|

|

| frequency arc initiation. |

|

|

|

|

|

|

|

|

|

| ramp up and ramp down of the weld- | |

|

|

|

|

|

|

|

|

|

|

|

|

| ing current using the amptrol. The | ||

|

|

| AC TIG - AC TIG welding with high |

|

|

|

|

|

|

| start and finish currents are linked | ||||

|

|

| frequency arc initiation. |

|

|

|

|

|

|

|

|

|

| together and are repesented by a | |

|

|

|

|

|

|

|

|

|

|

|

|

| parameter called Minimum Current. | ||

|

|

|

|

|

|

|

|

|

|

|

| (Refer to Figure B.5) |

| ||

|

|

| DC Touch Start TIG - DC TIG welding with |

|

|

|

|

| |||||||

|

|

| lift tig arc initiation. |

|

|

|

|

|

|

|

|

|

| Four Step - This mode is intended to | |

|

|

| Stick crisp mode - for Cellulosic electrodes |

|

|

|

|

|

|

| be used with an arc start switch. It will | ||||

|

|

| like Exx10. |

|

|

|

|

|

|

|

|

|

| not function properly in remote mode | |

|

|

|

|

|

|

|

|

|

|

|

|

| with a foot or hand amptrol plugged | ||

|

|

| Stick soft mode - for E7018 Low Hydrogen |

|

|

|

|

|

|

| in. In four step operation depressing | ||||

|

|

| electrodes. |

|

|

|

|

|

|

|

|

|

| an arc start switch will cause the | |

|

|

|

|

|

|

|

|

|

|

|

|

| machine to initiate the arc at the start | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

| current level. When the switch is | |

|

|

| AC Stick Mode - for AC Stick Electrodes. |

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

| released the machine will ramp up to | |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| the maximum current over the ups- | |

|

|

| Table B.2 |

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

| lope time. Depressing the arc start | ||

| B. TIG TRIGGER MODES |

|

|

|

|

|

|

|

|

|

| switch again causes the output to | |||

|

|

|

|

|

|

|

|

|

|

| ramp down to the finish current level | ||||

|

|

| Two Step with Arc Start Switch - |

|

|

|

|

|

|

| over the downslope time. | Finally | |||

|

|

| This mode is available in local or |

|

|

|

|

|

|

| releasing the arc start switch causes | ||||

|

| 2S | remote modes but is typically used |

|

|

|

|

|

|

| the arc to go out. (Refer to Figure B.6) | ||||

|

|

| with an arc start switch. Depressing |

|

|

|

|

|

|

|

|

| |||

|

|

| the arc start switch will initiate the arc |

|

|

|

|

|

|

|

|

| |||

|

|

| at the start current level and ramp up |

|

|

|

|

|

|

|

| (3A) | |||

|

|

| the output to the maximum current |

|

|

|

|

|

|

|

|

| |||

|

|

| over the time set by the upslope time. |

|

|

|

|

|

|

|

|

| |||

|

|

| Releasing the switch will cause the |

|

|

|

|

|

|

|

|

| |||

|

|

| output amperage to ramp down to the |

|

|

|

|

|

|

|

|

| |||

|

|

| finish current over the downslope time |

|

|

|

|

|

|

|

|

| |||

|

|

| and then turn off the output. | In this |

|

|

|

| |||||||

|

|

| mode the start current and finish cur- |

|

|

|

|

| |||||||

|

|

| rent can be independently set and |

|

|

|

|

|

|

|

|

| |||

|

|

| upslope and downslope times are |

| FIGURE B.6 | ||||||||||

|

|

| adjustable. (Refer to Figure B.5) |

|

|

|

|

|

|

|

|

| |||

|

|

| (1) | (2) | (3) |

|

|

|

|

|

|

|

|

|

|

|

|