|

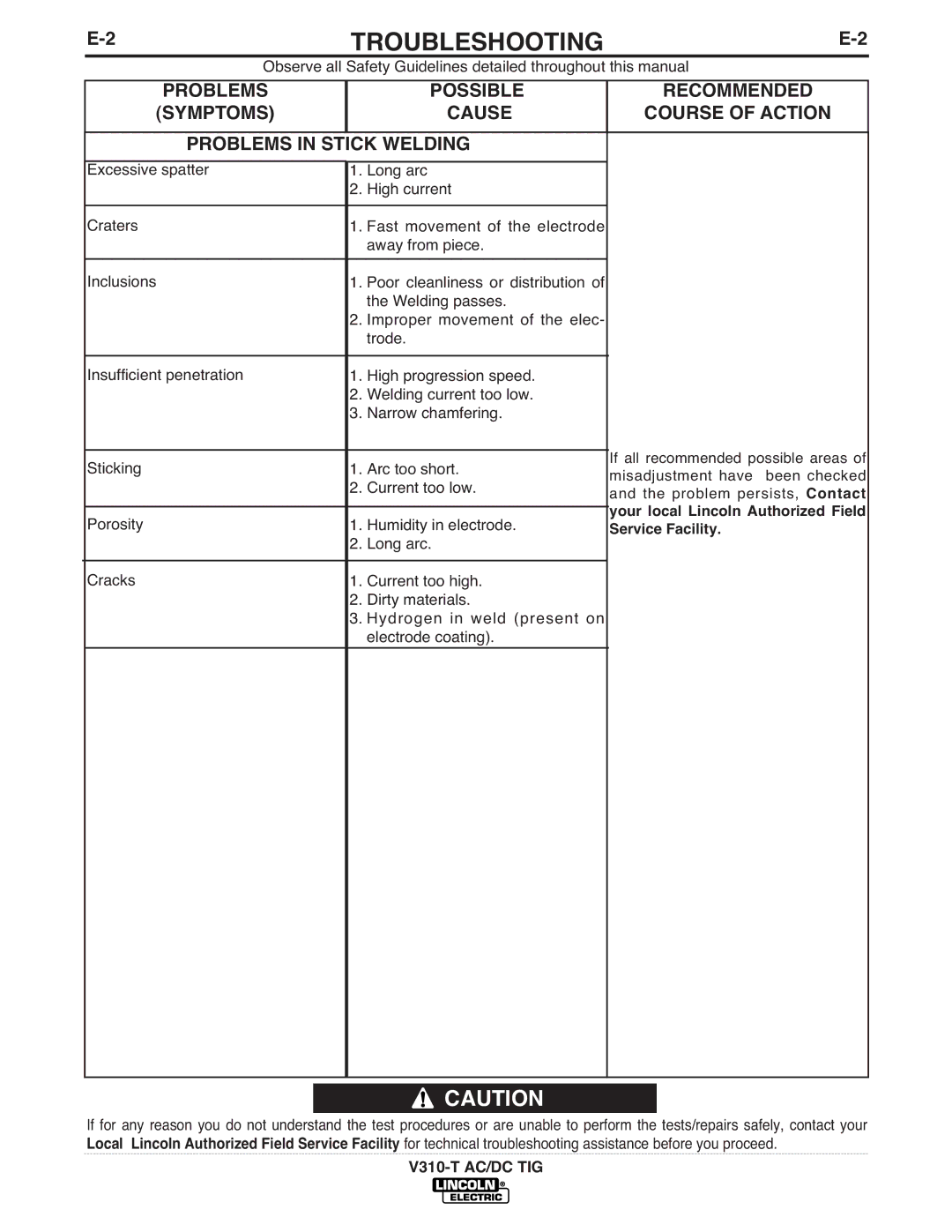

| TROUBLESHOOTING |

|

| |||

|

| Observe all Safety Guidelines detailed throughout this manual |

| ||||

|

| PROBLEMS |

| POSSIBLE |

| RECOMMENDED |

|

|

|

|

|

| |||

|

| (SYMPTOMS) |

| CAUSE |

| COURSE OF ACTION |

|

|

| PROBLEMS IN STICK WELDING |

|

|

| ||

|

|

|

|

| |||

| Excessive spatter | 1. | Long arc |

|

|

| |

|

|

| 2. | High current |

|

|

|

| Craters |

| 1. | Fast movement of the electrode |

|

|

|

|

|

|

| away from piece. |

|

|

|

| Inclusions | 1. | Poor cleanliness or distribution of |

|

|

| |

|

|

| 2. | the Welding passes. |

|

|

|

|

|

| Improper movement of the elec- |

|

|

| |

|

|

|

| trode. |

|

|

|

| Insufficient penetration | 1. | High progression speed. |

|

|

| |

|

|

| 2. | Welding current too low. |

|

|

|

|

|

| 3. | Narrow chamfering. |

| If all recommended possible areas of | |

| Sticking |

| 1. | Arc too short. |

| ||

|

|

| misadjustment have been checked | ||||

|

|

| 2. | Current too low. |

| and the problem persists, Contact | |

|

|

|

|

|

| your local Lincoln Authorized Field | |

| Porosity |

| 1. | Humidity in electrode. |

| ||

|

|

| Service Facility. |

| |||

|

|

| 2. | Long arc. |

|

| |

| Cracks |

| 1. | Current too high. |

|

|

|

|

|

| 2. | Dirty materials. |

|

|

|

|

|

| 3. Hydrogen in weld (present on |

|

|

| |

|

|

|

| electrode coating). |

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.