Return to Section TOC

TOC

Return to Master TOC

TOC

THEORY OF OPERATION

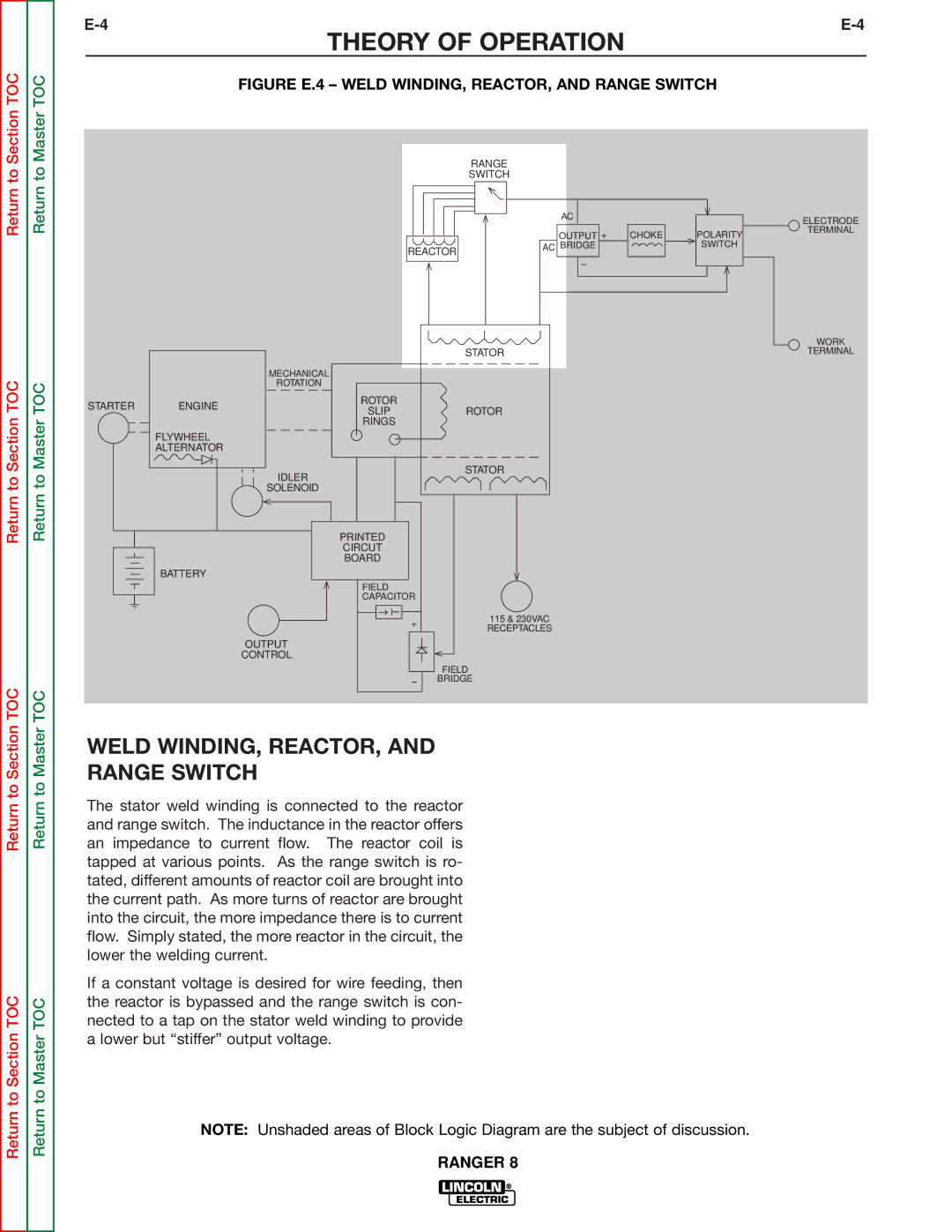

FIGURE E.4 – WELD WINDING, REACTOR, AND RANGE SWITCH

RANGE

SWITCH

| AC |

|

| ELECTRODE |

|

|

|

| |

| OUTPUT | CHOKE | POLARITY | TERMINAL |

|

| |||

REACTOR | AC BRIDGE |

| SWITCH |

|

|

|

|

|

| WORK |

STATOR | TERMINAL |

MECHANICAL

ROTATION

ROTOR

STARTER ENGINESLIPROTOR

RINGS

Section

to Master

FLYWHEEL

ALTERNATOR

IDLER

STATOR

Return to

Return to Section TOC

Return to Section TOC

Return

Return to Master TOC

Return to Master TOC

SOLENOID

PRINTED

CIRCUT

BOARD

BATTERY

FIELD

CAPACITOR

115 & 230VAC

RECEPTACLES

OUTPUT

CONTROL

FIELD

BRIDGE

WELD WINDING, REACTOR, AND

RANGE SWITCH

The stator weld winding is connected to the reactor and range switch. The inductance in the reactor offers an impedance to current flow. The reactor coil is tapped at various points. As the range switch is ro- tated, different amounts of reactor coil are brought into the current path. As more turns of reactor are brought into the circuit, the more impedance there is to current flow. Simply stated, the more reactor in the circuit, the lower the welding current.

If a constant voltage is desired for wire feeding, then the reactor is bypassed and the range switch is con- nected to a tap on the stator weld winding to provide a lower but “stiffer” output voltage.

NOTE: Unshaded areas of Block Logic Diagram are the subject of discussion.