Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING & REPAIR

ROTOR VOLTAGE TEST (continued)

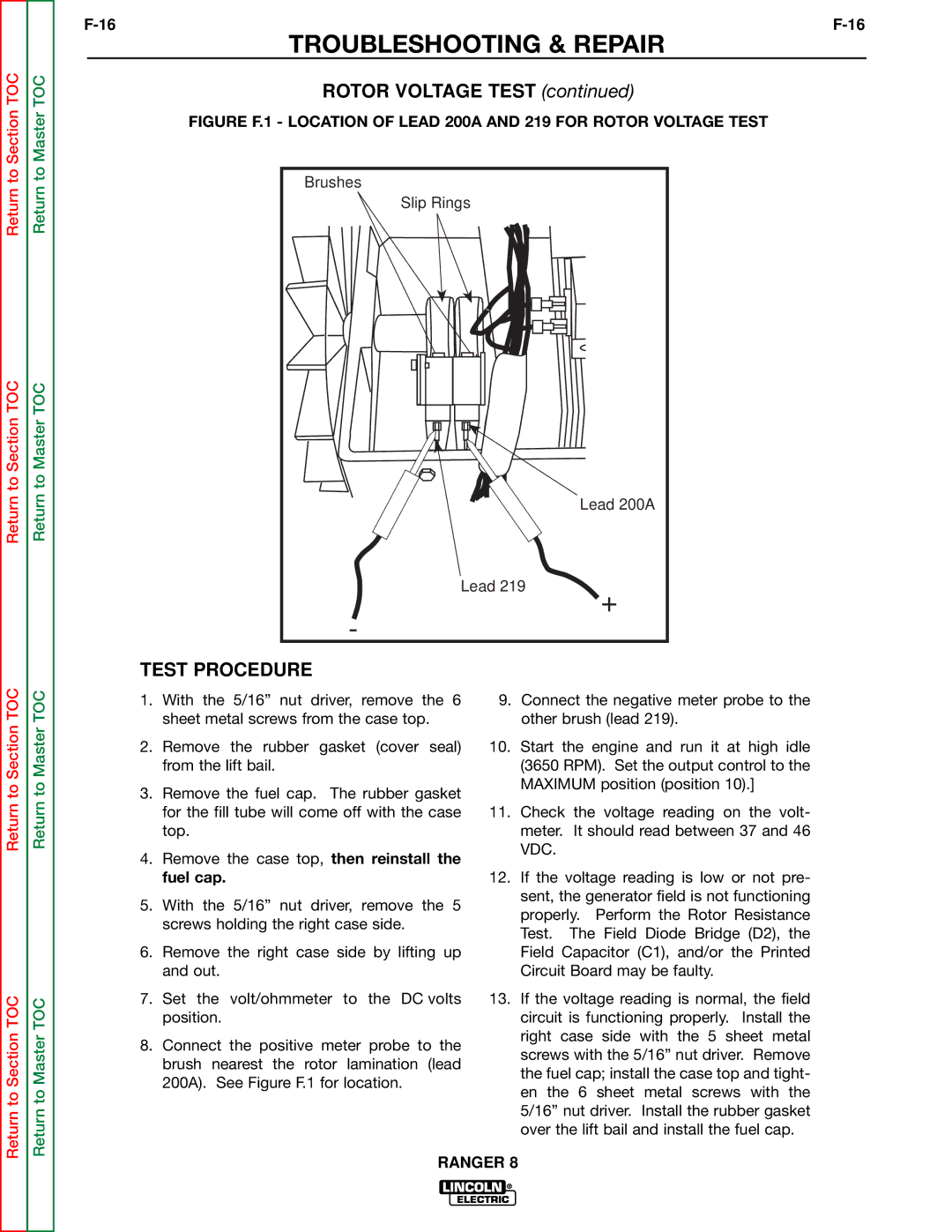

FIGURE F.1 - LOCATION OF LEAD 200A AND 219 FOR ROTOR VOLTAGE TEST

Brushes |

| |

Slip Rings |

| |

| Lead 200A | |

Lead 219 | + | |

- | ||

|

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TEST PROCEDURE

1.With the 5/16” nut driver, remove the 6 sheet metal screws from the case top.

2.Remove the rubber gasket (cover seal) from the lift bail.

3.Remove the fuel cap. The rubber gasket for the fill tube will come off with the case top.

4.Remove the case top, then reinstall the fuel cap.

5.With the 5/16” nut driver, remove the 5 screws holding the right case side.

6.Remove the right case side by lifting up and out.

7.Set the volt/ohmmeter to the DC volts position.

8.Connect the positive meter probe to the brush nearest the rotor lamination (lead 200A). See Figure F.1 for location.

9.Connect the negative meter probe to the other brush (lead 219).

10.Start the engine and run it at high idle (3650 RPM). Set the output control to the MAXIMUM position (position 10).]

11.Check the voltage reading on the volt- meter. It should read between 37 and 46 VDC.

12.If the voltage reading is low or not pre- sent, the generator field is not functioning properly. Perform the Rotor Resistance Test. The Field Diode Bridge (D2), the Field Capacitor (C1), and/or the Printed Circuit Board may be faulty.

13.If the voltage reading is normal, the field circuit is functioning properly. Install the right case side with the 5 sheet metal screws with the 5/16” nut driver. Remove the fuel cap; install the case top and tight- en the 6 sheet metal screws with the 5/16” nut driver. Install the rubber gasket over the lift bail and install the fuel cap.