Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

OPERATION |

| ||||||

|

|

|

|

| |||

|

|

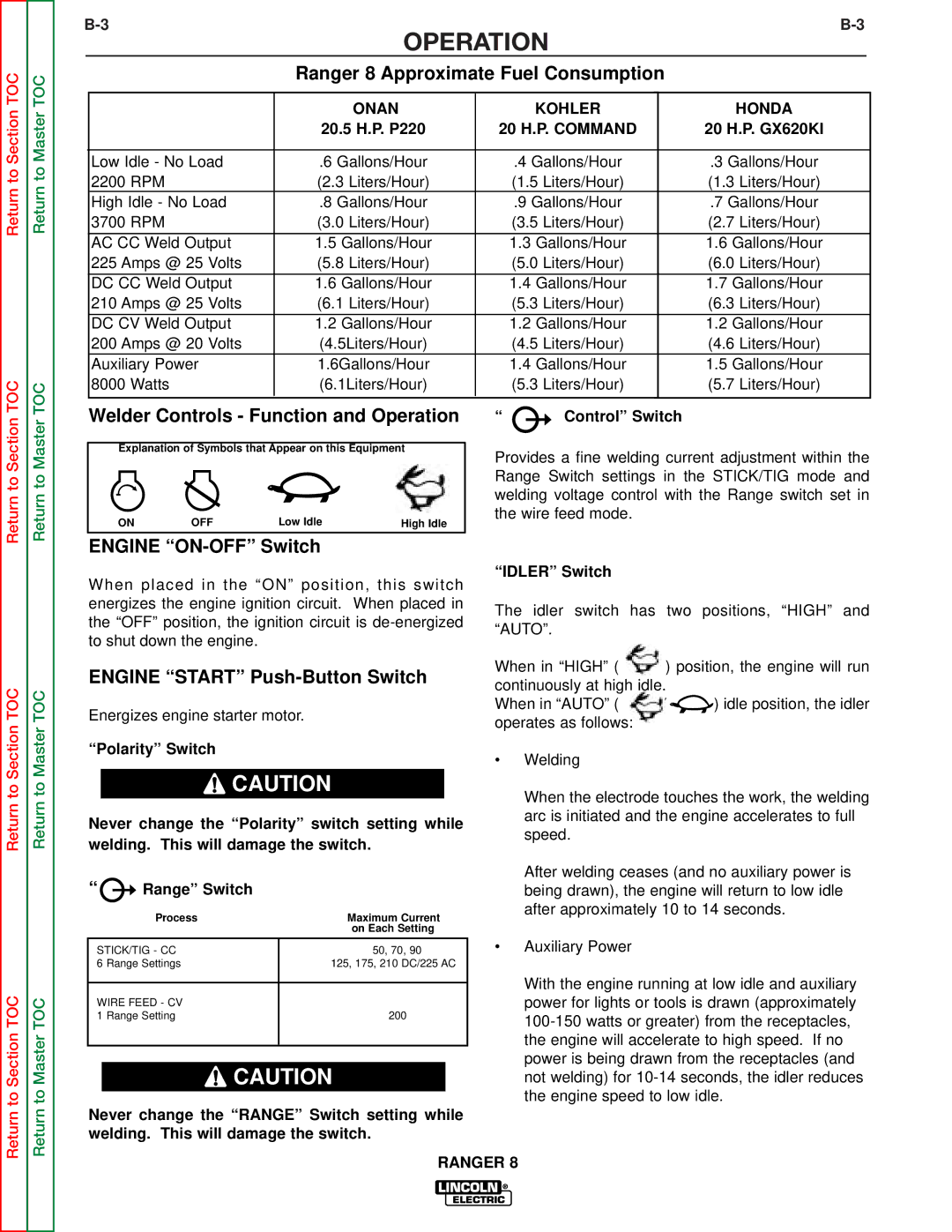

| Ranger 8 Approximate Fuel Consumption |

|

| ||

|

|

|

|

|

|

|

|

|

|

| ONAN | KOHLER |

| HONDA |

|

|

|

| 20.5 H.P. P220 | 20 H.P. COMMAND |

| 20 H.P. GX620KI |

|

|

|

|

|

|

|

|

|

|

| Low Idle - No Load | .6 Gallons/Hour | .4 Gallons/Hour |

| .3 Gallons/Hour |

|

|

| 2200 RPM | (2.3 Liters/Hour) | (1.5 Liters/Hour) |

| (1.3 Liters/Hour) |

|

|

| High Idle - No Load | .8 Gallons/Hour | .9 Gallons/Hour |

| .7 Gallons/Hour |

|

|

| 3700 RPM | (3.0 Liters/Hour) | (3.5 Liters/Hour) |

| (2.7 Liters/Hour) |

|

|

|

|

|

|

|

|

|

|

| AC CC Weld Output | 1.5 Gallons/Hour | 1.3 Gallons/Hour |

| 1.6 Gallons/Hour |

|

|

| 225 Amps @ 25 Volts | (5.8 Liters/Hour) | (5.0 Liters/Hour) |

| (6.0 Liters/Hour) |

|

|

| DC CC Weld Output | 1.6 Gallons/Hour | 1.4 Gallons/Hour |

| 1.7 Gallons/Hour |

|

|

| 210 Amps @ 25 Volts | (6.1 Liters/Hour) | (5.3 Liters/Hour) |

| (6.3 Liters/Hour) |

|

|

|

|

|

|

|

|

|

|

| DC CV Weld Output | 1.2 Gallons/Hour | 1.2 Gallons/Hour |

| 1.2 Gallons/Hour |

|

|

| 200 Amps @ 20 Volts | (4.5Liters/Hour) | (4.5 Liters/Hour) |

| (4.6 Liters/Hour) |

|

|

| Auxiliary Power | 1.6Gallons/Hour | 1.4 Gallons/Hour |

| 1.5 Gallons/Hour |

|

|

| 8000 Watts | (6.1Liters/Hour) | (5.3 Liters/Hour) |

| (5.7 Liters/Hour) |

|

|

|

|

|

|

|

|

|

Welder Controls - Function and Operation | “ | Control” Switch | ||||||||

|

|

|

|

|

|

|

| |||

| Explanation of Symbols that Appear on this Equipment | Provides a fine welding current adjustment within the | ||||||||

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| Range Switch settings in the STICK/TIG mode and | |

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| welding voltage control with the Range switch set in | |

|

|

|

|

|

|

|

|

| the wire feed mode. | |

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| ||

| ON |

| OFF |

|

| Low Idle |

| High Idle | ||

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

ENGINE “ON-OFF” Switch

When placed in the “ON” position, this switch energizes the engine ignition circuit. When placed in the “OFF” position, the ignition circuit is

ENGINE “START” Push-Button Switch

Energizes engine starter motor.

“Polarity” Switch

![]() CAUTION

CAUTION

Never change the “Polarity” switch setting while welding. This will damage the switch.

“ | Range” Switch |

|

|

|

|

|

|

| Process | Maximum Current | |

|

| on Each Setting |

|

STICK/TIG - CC | 50, 70, 90 |

| |

6 | Range Settings | 125, 175, 210 DC/225 AC | |

|

|

| |

WIRE FEED - CV |

|

| |

1 | Range Setting | 200 |

|

|

|

|

|

![]() CAUTION

CAUTION

Never change the “RANGE” Switch setting while welding. This will damage the switch.

“IDLER” Switch

The idler switch has two positions, “HIGH” and “AUTO”.

When in “HIGH” ( ![]() ) position, the engine will run continuously at high idle.

) position, the engine will run continuously at high idle.

When in “AUTO” ( / ![]() ) idle position, the idler operates as follows:

) idle position, the idler operates as follows:

•Welding

When the electrode touches the work, the welding arc is initiated and the engine accelerates to full speed.

After welding ceases (and no auxiliary power is being drawn), the engine will return to low idle after approximately 10 to 14 seconds.

•Auxiliary Power

With the engine running at low idle and auxiliary power for lights or tools is drawn (approximately